Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Arm wrestling the leading edge...

- Thread starter aarvig

- Start date

You ain't the Lone Ranger

I distinctly remember trying to cleco the leading edge skins the first time. I was having to strong arm it so much that I was convinced that something was wrong and that someone had shipped me the wrong parts.

Not to worry. That is the way it is supposed to fit. It helps a little to start at the nose and cleco your way back toward the trailing edge, using the cradle. By the time you drill, debur, dimple, disassemble and then reassemble, it will go easier.

Talking to the errant part actually helps. The phrase, "Come on, Baby, you can do it" usually works for me. If not, you may have to progress to, "Help me out here Darlin, we can't fly until you give in just a little." In dire straits, I have had to resort to,"Open the pod bay doors Hal!!"

Let not your heart be troubled. The skins WILL go on and when she is flying, you will chuckle every time you run your hands over the leading edge and think to yourself, "You gave me a run for the money on this one girl, but we got through it."

Anyone else out there have a bear of a time clecoing the leading edge skin to the leading edge ribs? Whats the trick?

I distinctly remember trying to cleco the leading edge skins the first time. I was having to strong arm it so much that I was convinced that something was wrong and that someone had shipped me the wrong parts.

Not to worry. That is the way it is supposed to fit. It helps a little to start at the nose and cleco your way back toward the trailing edge, using the cradle. By the time you drill, debur, dimple, disassemble and then reassemble, it will go easier.

Talking to the errant part actually helps. The phrase, "Come on, Baby, you can do it" usually works for me. If not, you may have to progress to, "Help me out here Darlin, we can't fly until you give in just a little." In dire straits, I have had to resort to,"Open the pod bay doors Hal!!"

Let not your heart be troubled. The skins WILL go on and when she is flying, you will chuckle every time you run your hands over the leading edge and think to yourself, "You gave me a run for the money on this one girl, but we got through it."

Aaron, try this:

Out of the craddle.

Make sure to bent the forward rib tabs that will have no holes so they are square or a bit inwards with the rib web.

Start with the a middle rib and insert it in the skin with a 45 degree rotation (web downwards) instead of in line with the skin holes.

This way, you can easily insert a cleco on the most forward hole on the top skin.

Then spread slightly the skin and rotate the rib in line with the skin holes.

Repeat this one cleco on top for all ribs moving from center to outside.

Then go to the lower side, and insert a cleco in the most forward hole. You might need to insert it at a slight angle to "catch" the rib hole. The trick here is to keep the skin slightly away from the rib so the cleco can go in "angled".

Repeat this one cleco on bottom for all ribs moving from center to outside.

Then you're good to go, one hole at a time from front to back. Don't do one lone rib completely as you will "close the skin" too much on the ribs.

I did one or two front holes on top for all ribs, then one or two front holes on the bottom, then top again, bottom again... until you get to the rear. The bottom cleco are easier as there's less curve in the skin.

Once a third or half way though, it gets much easier.

And as Steve said, when the drilling and deburring is done, it's easier the second time around.

Have fun !!!

Out of the craddle.

Make sure to bent the forward rib tabs that will have no holes so they are square or a bit inwards with the rib web.

Start with the a middle rib and insert it in the skin with a 45 degree rotation (web downwards) instead of in line with the skin holes.

This way, you can easily insert a cleco on the most forward hole on the top skin.

Then spread slightly the skin and rotate the rib in line with the skin holes.

Repeat this one cleco on top for all ribs moving from center to outside.

Then go to the lower side, and insert a cleco in the most forward hole. You might need to insert it at a slight angle to "catch" the rib hole. The trick here is to keep the skin slightly away from the rib so the cleco can go in "angled".

Repeat this one cleco on bottom for all ribs moving from center to outside.

Then you're good to go, one hole at a time from front to back. Don't do one lone rib completely as you will "close the skin" too much on the ribs.

I did one or two front holes on top for all ribs, then one or two front holes on the bottom, then top again, bottom again... until you get to the rear. The bottom cleco are easier as there's less curve in the skin.

Once a third or half way though, it gets much easier.

And as Steve said, when the drilling and deburring is done, it's easier the second time around.

Have fun !!!

Brantel

Well Known Member

Grind/file/cut those bumps down that are on the ribs at the nose of the rib where the notches are for the flanges.

Those are the root of many problems.

If you don't, it is almost guaranteed that you will have a wavy leading edge and those bumps will show even after paint.

Ask me how I know

This will also make it easier to get the rib and the skin to mate!

Those are the root of many problems.

If you don't, it is almost guaranteed that you will have a wavy leading edge and those bumps will show even after paint.

Ask me how I know

This will also make it easier to get the rib and the skin to mate!

RogerGrahl

Member

Trick to getting the leading edge / fuel tank ribs in place.

First, put the skin on your padded workbench, not in the cradle. Put one cleco in the top most forward hole in each rib. At this point you will have all of the ribs in place with a single cleco in each rib.

Here's the trick. Rotate the rib about 20 degrees and push it at an angle so the bottom, forward hole in the rib lines up with the hole in the bottom skin. You'll have to push down on the top of the skin while pushing the rib into place. Have a helper put a single cleco in the bottom most forward hole. The skin will have to hang slightly over the edge of the bench so your helper can access the bottom, forward hole.

Next, rotate the rib back into position and add three more clecos through the top, forward holes. Do this for all of the ribs. At this point you will have all of your ribs installed with four clecos through the top skin and one cleco through the bottom skin.

Put two or three more clecos through the bottom, forward most holes. Now, put the leading edge / fuel tank in the cradle and finish clecoing every hole. Match drill by removing and replacing one cleco at a time.

It took very little pressure to get the ribs in place. Also, none of the holes were elongated from trying to force in a cleco. Rotating the rib around the single top and bottom cleco did no damage to the holes. It also helps to initially rotate the ribs toward the rib flange so when you get the first two clecos in place and rotate the rib back, the rib flange won't dig into the skin.

I wish I would have taken pictures. It is easier to see than describe.

First, put the skin on your padded workbench, not in the cradle. Put one cleco in the top most forward hole in each rib. At this point you will have all of the ribs in place with a single cleco in each rib.

Here's the trick. Rotate the rib about 20 degrees and push it at an angle so the bottom, forward hole in the rib lines up with the hole in the bottom skin. You'll have to push down on the top of the skin while pushing the rib into place. Have a helper put a single cleco in the bottom most forward hole. The skin will have to hang slightly over the edge of the bench so your helper can access the bottom, forward hole.

Next, rotate the rib back into position and add three more clecos through the top, forward holes. Do this for all of the ribs. At this point you will have all of your ribs installed with four clecos through the top skin and one cleco through the bottom skin.

Put two or three more clecos through the bottom, forward most holes. Now, put the leading edge / fuel tank in the cradle and finish clecoing every hole. Match drill by removing and replacing one cleco at a time.

It took very little pressure to get the ribs in place. Also, none of the holes were elongated from trying to force in a cleco. Rotating the rib around the single top and bottom cleco did no damage to the holes. It also helps to initially rotate the ribs toward the rib flange so when you get the first two clecos in place and rotate the rib back, the rib flange won't dig into the skin.

I wish I would have taken pictures. It is easier to see than describe.

Av8torTom

Well Known Member

HUGE struggle

Aaron,

I had a very difficult time making the nose ribs fit. Using the techniques described here by others I was able to wrestle them into place. When I was don I had a completely unacceptable wavy leading edge. Talking to Vans, then recommended I re-shape the nose ribs to improve the fit. The last thing you want to be doing when you have proseal on everything is struggling to get things in place.

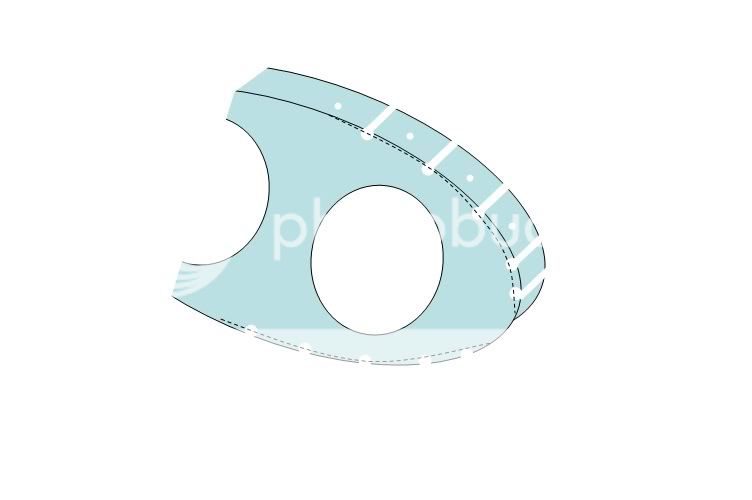

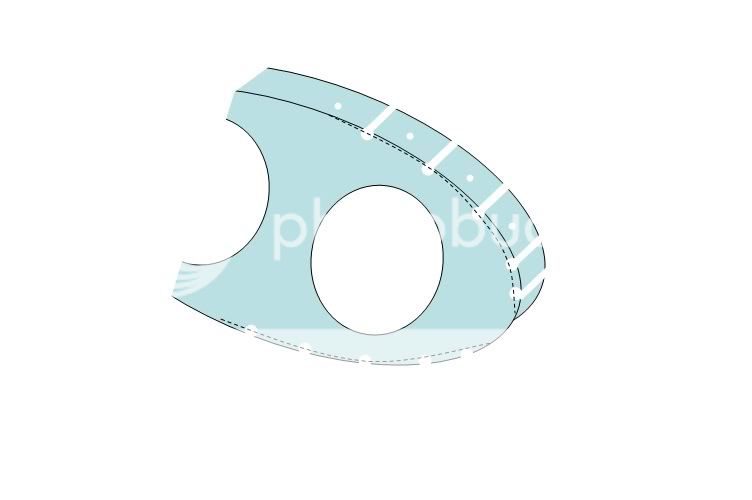

This is an illustration of what I had to do with a hammer and pliers. It's a little exaggerated for illustration purposes, but not much. The dotted line shows the new profile. Go easy and take your time - adjust a little at time.

Aaron,

I had a very difficult time making the nose ribs fit. Using the techniques described here by others I was able to wrestle them into place. When I was don I had a completely unacceptable wavy leading edge. Talking to Vans, then recommended I re-shape the nose ribs to improve the fit. The last thing you want to be doing when you have proseal on everything is struggling to get things in place.

This is an illustration of what I had to do with a hammer and pliers. It's a little exaggerated for illustration purposes, but not much. The dotted line shows the new profile. Go easy and take your time - adjust a little at time.

mvidalr

Well Known Member

Struggle with the skin and ribs, but do not struggle with the clecos!

Maybe this is already known to many builders, or probably common sense, but i learned the hard way during empennage construction and was tempted to do the same thing with the leading edge and ribs.

Whatever you do, as soon as you start placing the first clecos in, DO NOT try to make the ribs fit by twisting, angling, or pushing/pulling on the clecos, as they will make the rivet holes uneven, or even oval, probably leading to some pillowing along the rivet lines after final riveting of the skin.

My two cents

Maybe this is already known to many builders, or probably common sense, but i learned the hard way during empennage construction and was tempted to do the same thing with the leading edge and ribs.

Whatever you do, as soon as you start placing the first clecos in, DO NOT try to make the ribs fit by twisting, angling, or pushing/pulling on the clecos, as they will make the rivet holes uneven, or even oval, probably leading to some pillowing along the rivet lines after final riveting of the skin.

My two cents

wjb

Well Known Member

The first time is tough

Getting the ribs in the first time, especially with the tank with its thicker skin, is sure a challenge. At one point, I was really questioning if it could be done at all (even though lots of others have done it). I found that Jason Beaver's method worked well. Dump the cradle. Straddle the skin. Put something firm but pliable under the leading edge (I used some pretty dense packing foam), and then push hard on the trailing edge flange until the holes line up. It helps if you have a a cleco already inserted into the last two holes in the skin, so you can snap them into place once the rib is in position.

It's funny, after this maneuver, I thought "how the heck am I gonna do this with proseal gooped all over the place?" Happily, after the drilling to size and dimpling, things went together easily. I did use a bit of a pry bar (a sharp poker that I inserted thru the skin, thru the rib hole, and levered everything into place prior to the first cleco) to get the alignment right, but it was quite a bit easier than expected. Thank God!

The first time is really the hardest .. all other assemblies are 10x + easier.

Keep at it; once you get it, you're done!

Getting the ribs in the first time, especially with the tank with its thicker skin, is sure a challenge. At one point, I was really questioning if it could be done at all (even though lots of others have done it). I found that Jason Beaver's method worked well. Dump the cradle. Straddle the skin. Put something firm but pliable under the leading edge (I used some pretty dense packing foam), and then push hard on the trailing edge flange until the holes line up. It helps if you have a a cleco already inserted into the last two holes in the skin, so you can snap them into place once the rib is in position.

It's funny, after this maneuver, I thought "how the heck am I gonna do this with proseal gooped all over the place?" Happily, after the drilling to size and dimpling, things went together easily. I did use a bit of a pry bar (a sharp poker that I inserted thru the skin, thru the rib hole, and levered everything into place prior to the first cleco) to get the alignment right, but it was quite a bit easier than expected. Thank God!

The first time is really the hardest .. all other assemblies are 10x + easier.

Keep at it; once you get it, you're done!

Last edited:

aarvig

Well Known Member

Thanks for all the replies guys. I ended up basically straddling the LE skin and forcing the trailing edge of the rib down. I didn't catch the post about sanding the notches out of the leading edge flanges until after I cleco'd them into place. DARN. I have some nice waves on my leading edge. Oh well, I disassembled the leading edege assembly, filed and sanded them down and reassembled. Waves are still there but hopefully they go away when riveted together. Overall I'm happy with the results. My arms and hands are tired now. I also have to go to confession...

wjb

Well Known Member

Thanks for all the replies guys. I ended up basically straddling the LE skin and forcing the trailing edge of the rib down. I didn't catch the post about sanding the notches out of the leading edge flanges until after I cleco'd them into place. DARN. I have some nice waves on my leading edge. Oh well, I disassembled the leading edge assembly, filed and sanded them down and reassembled. Waves are still there but hopefully they go away when riveted together. Overall I'm happy with the results. My arms and hands are tired now. I also have to go to confession...

OK .. you did it right. Your sins our forgiven ... your penance: 100 dimples and 1000 clecos. (and you got off easy!). This was exactly what I experienced; you're through the hard part. Though, I didn't get any waves in my LE (I did run the ribs thru the scotchbrite disk prior)