vlittle

Well Known Member

I apologize for not having a photo (yet), but here's the scenario.

I noticed a smoking rivet at the outboard forward corner of the skin where the trim tab is cut out of the elevator. At this point, the rear stub spar of the elevator intersects an elevator rib. The elevator skin overhangs and the trim tab hinge is riveted to this overhang.

The outboard portion of the hinge has a lot of stress from the trim tab flexing the skin. This is where I noticed the smoking rivet. I think that there is a high probability of a crack if this is not addressed. The trim tab on the RV-9 is much larger than most of the other RVs, so I expect the strain on this junction to be greater.

My solution was to make a reinforcing bracket that connects the elevator rib to the hinge. I will post a photo later with the details, so this is just a heads up to inspect this weak point. Aircraft flight time is close to 500 hrs.

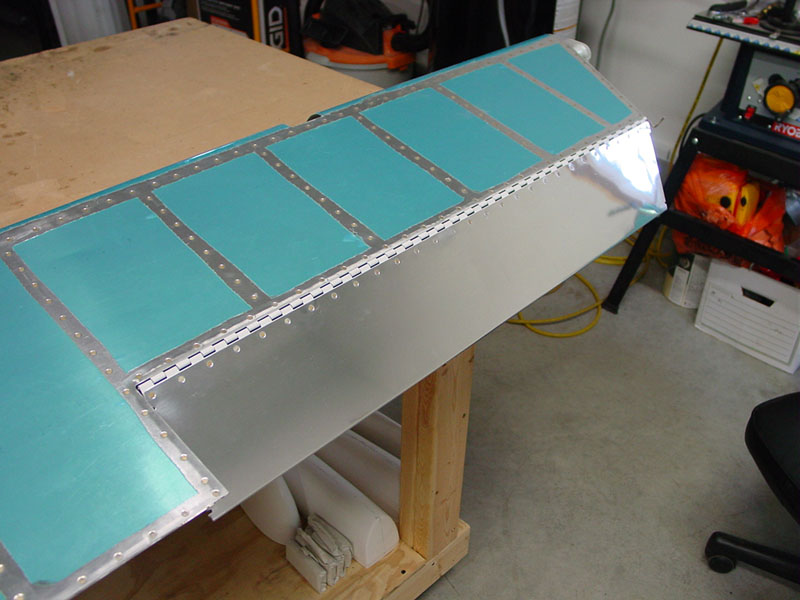

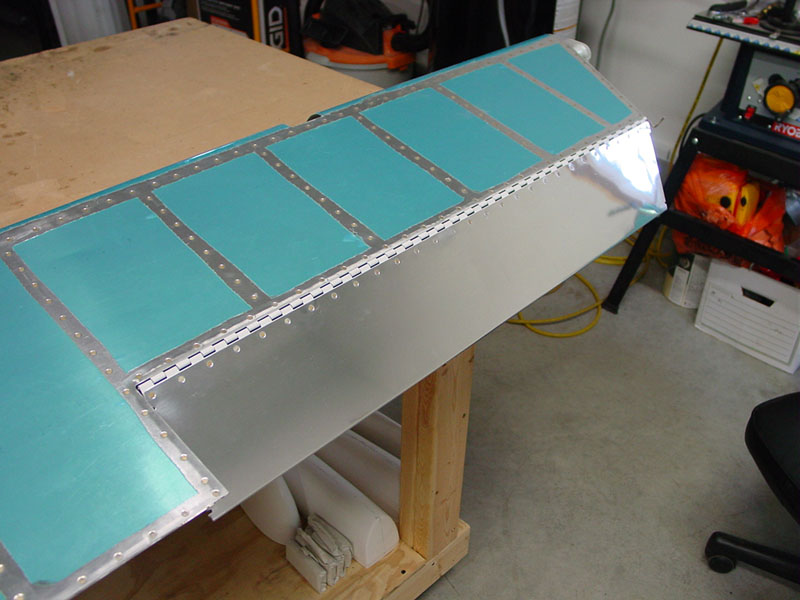

EDIT: this is not my elevator, I just grabbed the pic from the interweb for illustration:

I noticed a smoking rivet at the outboard forward corner of the skin where the trim tab is cut out of the elevator. At this point, the rear stub spar of the elevator intersects an elevator rib. The elevator skin overhangs and the trim tab hinge is riveted to this overhang.

The outboard portion of the hinge has a lot of stress from the trim tab flexing the skin. This is where I noticed the smoking rivet. I think that there is a high probability of a crack if this is not addressed. The trim tab on the RV-9 is much larger than most of the other RVs, so I expect the strain on this junction to be greater.

My solution was to make a reinforcing bracket that connects the elevator rib to the hinge. I will post a photo later with the details, so this is just a heads up to inspect this weak point. Aircraft flight time is close to 500 hrs.

EDIT: this is not my elevator, I just grabbed the pic from the interweb for illustration:

Last edited: