Rick_A

Well Known Member

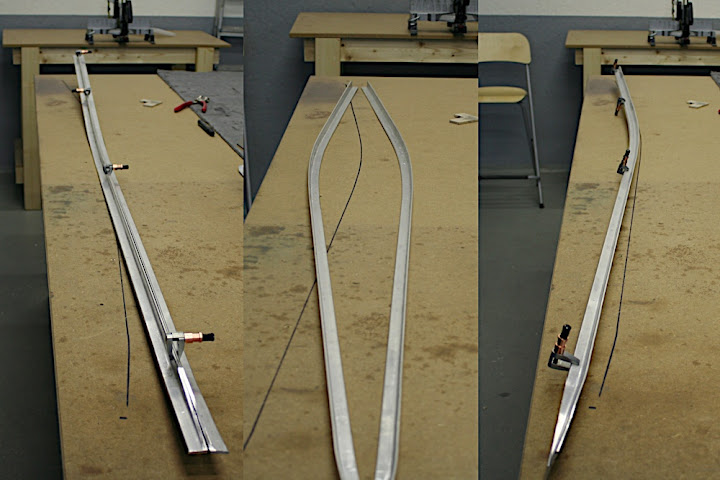

I'm close to finishing the longerons, in fact I thought I was done with the bending. However, I not sure that I really understand the end goal of modifying the forward angles.

I opened up the forward section by 5.4 degrees and then worked on putting in the 2.7 degree twist.

1. So when I'm done, is the angle still suppose to be 95.4 degrees?

2. Is the point of the 2.7 degree twist to make top face of the longeron flat across it's entire length?

3. If the answer to #2 is yes, does that make side of the longeron (the face that is against the side skin) flare outward? If so, by how much? (5.4 deg?)

I test fit one side skins today. I appears that having the side of the angle flare outward will induce a crease in the skin when it is riveted to longeron.

I also placed the panel base across the longerons and it looks to me like the top faces of the longerons should be flat and in the same plane as the rest of the longeron.

If any one as a pic that they can't post showing the front angle of the longeron looking aft, that would be a big help.

I opened up the forward section by 5.4 degrees and then worked on putting in the 2.7 degree twist.

1. So when I'm done, is the angle still suppose to be 95.4 degrees?

2. Is the point of the 2.7 degree twist to make top face of the longeron flat across it's entire length?

3. If the answer to #2 is yes, does that make side of the longeron (the face that is against the side skin) flare outward? If so, by how much? (5.4 deg?)

I test fit one side skins today. I appears that having the side of the angle flare outward will induce a crease in the skin when it is riveted to longeron.

I also placed the panel base across the longerons and it looks to me like the top faces of the longerons should be flat and in the same plane as the rest of the longeron.

If any one as a pic that they can't post showing the front angle of the longeron looking aft, that would be a big help.