HAL Pilot

Well Known Member

Aloha all

So finally got my replacement QB Fuse (The original never made it to me due to the corrosion issues in 2020.) Only 14 months later than expected. Not a slam on Vans, beyond their control, but some folks are trying to figure out where they stand on delivery. My original delivery date was supposed to be Nov 2020. I ordered at the beginning of the year.

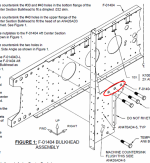

Going through the WIKI threads to QC the build and find that the holes that were supposed to be reamed out on step 1 of page 25-06 were "probably" not done all the way through the F-01404 bulkhead or not done at all on the LEFT side. Right side seems OK. I can not get a .375 drill bit shank (measured it on a micrometer) into the hole from the tail side. Front side it can go in.

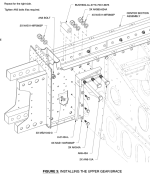

Hole number 1 has a corresponding hole on the front bulkhead so I can Ream as requested per the plans.

Hole number 2 and 3 can only be reamed from the back. An angle drill and Cut down or short "reamer" would not be long enough to go all the way through from the front due to the other (front) bulkhead being so close.

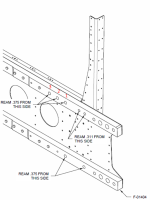

As Reference Fig 3 shows the gear brace that will go in this location.

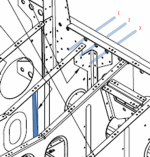

The rib attached to the bulkhead just under hole 2 is pretty stiff due to the "blue highlighted" stiffener so pushing it out of the way and getting a completely straight shot at that hole from the back will be difficult. Either way the only fix I see is reaming from the back.

I am not looking for "fixes" from VAF folks. unless you are a aerospace engineer, as I would be more comfortable with an engineering answer from the mother ship, and have a question in with them. I will post their answer when received.

Just posting here for two reasons.

1. If you miss this step in your slow build its going to be a problem

2. If you are getting a QB this will be an area to double check before starting to build.

So finally got my replacement QB Fuse (The original never made it to me due to the corrosion issues in 2020.) Only 14 months later than expected. Not a slam on Vans, beyond their control, but some folks are trying to figure out where they stand on delivery. My original delivery date was supposed to be Nov 2020. I ordered at the beginning of the year.

Going through the WIKI threads to QC the build and find that the holes that were supposed to be reamed out on step 1 of page 25-06 were "probably" not done all the way through the F-01404 bulkhead or not done at all on the LEFT side. Right side seems OK. I can not get a .375 drill bit shank (measured it on a micrometer) into the hole from the tail side. Front side it can go in.

Hole number 1 has a corresponding hole on the front bulkhead so I can Ream as requested per the plans.

Hole number 2 and 3 can only be reamed from the back. An angle drill and Cut down or short "reamer" would not be long enough to go all the way through from the front due to the other (front) bulkhead being so close.

As Reference Fig 3 shows the gear brace that will go in this location.

The rib attached to the bulkhead just under hole 2 is pretty stiff due to the "blue highlighted" stiffener so pushing it out of the way and getting a completely straight shot at that hole from the back will be difficult. Either way the only fix I see is reaming from the back.

I am not looking for "fixes" from VAF folks. unless you are a aerospace engineer, as I would be more comfortable with an engineering answer from the mother ship, and have a question in with them. I will post their answer when received.

Just posting here for two reasons.

1. If you miss this step in your slow build its going to be a problem

2. If you are getting a QB this will be an area to double check before starting to build.

Attachments

Last edited: