Monday afternoon at 7000 ft. right over KOCF on our way to Sun-n-Fun I had the opportunity to put all that engine-out training to work. The good news first: This was the best case possible, no one hurt, no airplane damage, flew the plane, declared emergency, landed on the paved runway, made the first taxiway. Guardian angle working overtime!!

Now for the important details that I believe can have a positive effect on others building or flying RV's.

Root cause of the engine failure was that the filtered airbox came off the throttle body, wedged under the intake portion of the throttle body and disrupted the airflow through the metering venturi. This caused the mixture to go way out of wack as the engine went to an extreme rich condition, I saw fuel flow rates pegged at >30 gph as soon as the event occurred.

My airplane is an RV-10 with a stock engine install and a stock cowling. I have the Airflow Performance fuel injection system with a vertical mount FM-200 fuel servo. This is the critical issue. The FM-200 uses an aluminum clamping doughnut to retain the filtered airbox assembly. This system does not use safety-wired bolts on the filtered side of the airbox, just this clamping doughnut. If the doughnut looses it's grip on the throttle body the whole filtered airbox can slide downwards and fall off, in this case that is exactly what happend. When we pulled the top cowling off, there in the bottom sat the entire filtered airbox, clamping doughnut and all.

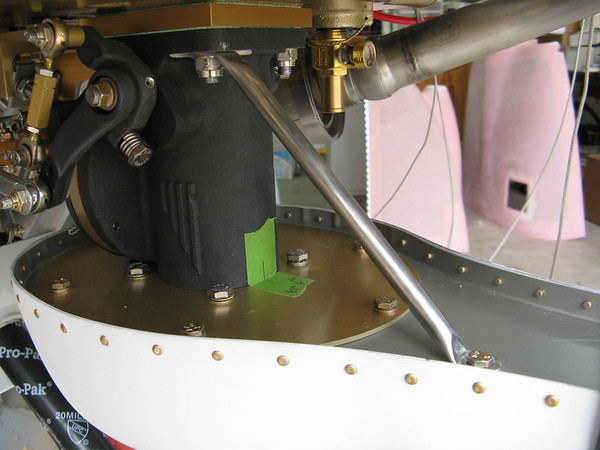

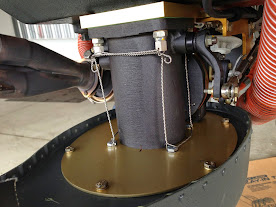

Now for the fix: The filtered airbox bolts are located right underneath the mounting studs for the throttle body assembly. I simply replaced these bolts with drilled head bolts and made some drilled coupling nuts to put on the throttle body studs, there was plenty of extra threads exposed on these studs so I didn't have to make any changes to the studs or the nuts that hold the throttle body in place. Then just safety wire the whole thing together. I used 0.040 wire to tie each filtered airbox bolt up to the mounting studs. Below are pictures of the drilled nuts and the final installation.

Obviously I would highly recommend that if you have an Airflow Performance fuel injection system with a vertically mounted fuel servo you take a look at your installation and consider adding some securing means to ensure this thing can't come apart on your airplane. They key issue is that disrupting the airflow inside the fuel servo can make the engine STOP RUNNING!

Lastly, I've collected the flight data out of my AFS EFIS system which I just happened to have running at 2 second intervals. Its been very instructive to see exactly how the whole event played out. I could see my various attempts to get the engine to run properly by changing throttle positions and the hopeless lack of actual power. You could see the excess fuel just crater the EGTs, and now in hind sight I may have been able to get some power back if I had the insight to try and close the mixture radically. However, I can say with confidence my total focus after about 1 or so minutes of trying to get power was on flying the plane to a safe landing.... mission accomplished.

Bob Newman

N541RV 200 hrs

Now for the important details that I believe can have a positive effect on others building or flying RV's.

Root cause of the engine failure was that the filtered airbox came off the throttle body, wedged under the intake portion of the throttle body and disrupted the airflow through the metering venturi. This caused the mixture to go way out of wack as the engine went to an extreme rich condition, I saw fuel flow rates pegged at >30 gph as soon as the event occurred.

My airplane is an RV-10 with a stock engine install and a stock cowling. I have the Airflow Performance fuel injection system with a vertical mount FM-200 fuel servo. This is the critical issue. The FM-200 uses an aluminum clamping doughnut to retain the filtered airbox assembly. This system does not use safety-wired bolts on the filtered side of the airbox, just this clamping doughnut. If the doughnut looses it's grip on the throttle body the whole filtered airbox can slide downwards and fall off, in this case that is exactly what happend. When we pulled the top cowling off, there in the bottom sat the entire filtered airbox, clamping doughnut and all.

Now for the fix: The filtered airbox bolts are located right underneath the mounting studs for the throttle body assembly. I simply replaced these bolts with drilled head bolts and made some drilled coupling nuts to put on the throttle body studs, there was plenty of extra threads exposed on these studs so I didn't have to make any changes to the studs or the nuts that hold the throttle body in place. Then just safety wire the whole thing together. I used 0.040 wire to tie each filtered airbox bolt up to the mounting studs. Below are pictures of the drilled nuts and the final installation.

Obviously I would highly recommend that if you have an Airflow Performance fuel injection system with a vertically mounted fuel servo you take a look at your installation and consider adding some securing means to ensure this thing can't come apart on your airplane. They key issue is that disrupting the airflow inside the fuel servo can make the engine STOP RUNNING!

Lastly, I've collected the flight data out of my AFS EFIS system which I just happened to have running at 2 second intervals. Its been very instructive to see exactly how the whole event played out. I could see my various attempts to get the engine to run properly by changing throttle positions and the hopeless lack of actual power. You could see the excess fuel just crater the EGTs, and now in hind sight I may have been able to get some power back if I had the insight to try and close the mixture radically. However, I can say with confidence my total focus after about 1 or so minutes of trying to get power was on flying the plane to a safe landing.... mission accomplished.

Bob Newman

N541RV 200 hrs