Tom Martin

Well Known Member

Earlier on I did some cowling pressure checks, not as elaborate as what these fellows are doing but it did help me get my head around what was happening.

In speaking with John Huft (currently fastest RV8) and Paul Lipps regarding the Coanda effect I made some fences in the bottom of the cowling to collect the air and deliver it smoothly to the outlet as shown in the picture below. Also note the almost closed spinner plate, the foam lightly rides on a thin layer of plastic tape that is on the prop shaft. I replace the foam about once a year, it is door and window frame sealant. Although the picture does not show the inlets they are very smooth and mate tightly to the baffles. On the upper left you can just see the outlet for the oil cooler, on the outside of the cowling I have a bluff body, CAFE inspired, that seems to work well. I would like to be able to duct the cooler down to the rear outlet but in my rocket there just is not enough room. The cowl flap is there but never needs to be opened. There is a sweet spot that is just shy of closed where everything seems to work best. I really should just glass the thing closed in that position. Note how far the cowl flap extends aft of the firewall. I have no heating problems in climb, but then I do live in Canada eh!

URL=http://imageshack.us/photo/my-images/813/img1878g.jpg/]

[/URL]

[/URL]

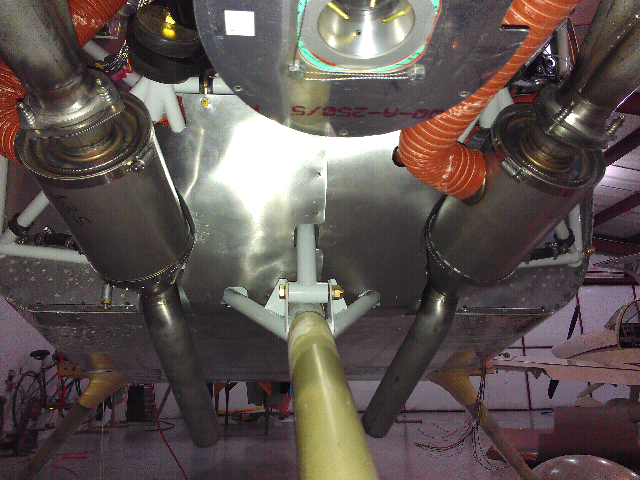

In the next picture you can see what goes on aft of the firewall. It is all about straightening the airflow, there is a fence on each side of the cowl exit and another right down the middle that does not show well in the picture. The small tube you see there is the sump drain for the throttle body. The black 1' tube is the crankcase vent. The aluminum plate goes from the bottom cross tube of the forward engine mount, back over all the hoses, back engine mount and extends aft about 18" The curved duct of the cowling mates up against this plate when the cowling is in place.

I have no idea what if any speed gains are attributed to this installation. I know that racing flat out I do not have any temperature issues. It would be nice to be able to do one change at a time, but that does not really work with my schedule. Hopefully we will be able to get some valuable information from the measurements that are being taken by the individuals in this thread. Before doing all this work, three winters ago, I looked at all the fast planes, RVs and glass, and noted that smooth flow, everywhere, was what separated them from slow planes. That was my mission and there is more that can be done. Currently I am running at my personal race speed limit, and all future gains will be made with cross country efficiency in mind.

Uploaded with ImageShack.us

In speaking with John Huft (currently fastest RV8) and Paul Lipps regarding the Coanda effect I made some fences in the bottom of the cowling to collect the air and deliver it smoothly to the outlet as shown in the picture below. Also note the almost closed spinner plate, the foam lightly rides on a thin layer of plastic tape that is on the prop shaft. I replace the foam about once a year, it is door and window frame sealant. Although the picture does not show the inlets they are very smooth and mate tightly to the baffles. On the upper left you can just see the outlet for the oil cooler, on the outside of the cowling I have a bluff body, CAFE inspired, that seems to work well. I would like to be able to duct the cooler down to the rear outlet but in my rocket there just is not enough room. The cowl flap is there but never needs to be opened. There is a sweet spot that is just shy of closed where everything seems to work best. I really should just glass the thing closed in that position. Note how far the cowl flap extends aft of the firewall. I have no heating problems in climb, but then I do live in Canada eh!

URL=http://imageshack.us/photo/my-images/813/img1878g.jpg/]

In the next picture you can see what goes on aft of the firewall. It is all about straightening the airflow, there is a fence on each side of the cowl exit and another right down the middle that does not show well in the picture. The small tube you see there is the sump drain for the throttle body. The black 1' tube is the crankcase vent. The aluminum plate goes from the bottom cross tube of the forward engine mount, back over all the hoses, back engine mount and extends aft about 18" The curved duct of the cowling mates up against this plate when the cowling is in place.

I have no idea what if any speed gains are attributed to this installation. I know that racing flat out I do not have any temperature issues. It would be nice to be able to do one change at a time, but that does not really work with my schedule. Hopefully we will be able to get some valuable information from the measurements that are being taken by the individuals in this thread. Before doing all this work, three winters ago, I looked at all the fast planes, RVs and glass, and noted that smooth flow, everywhere, was what separated them from slow planes. That was my mission and there is more that can be done. Currently I am running at my personal race speed limit, and all future gains will be made with cross country efficiency in mind.

Uploaded with ImageShack.us

Last edited: