Phil

Well Known Member

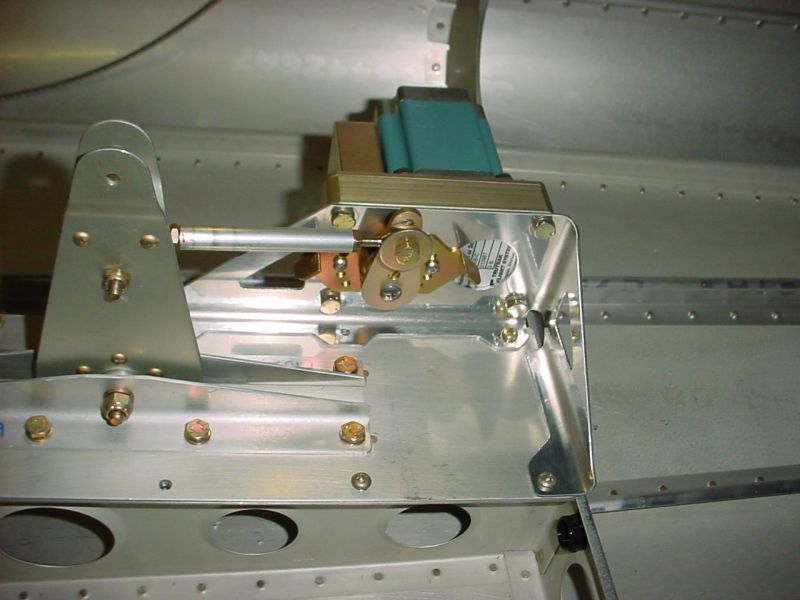

I'm getting ready to drop in my pitch servo at the elevator bell crank and trying to figure out where (or how) to locate the proper location for the attach hole.

This is the hole where the bar attaches to the bell crank arm.

http://www.trutrakflightsystems.com/documents/RV10pitch.pdf

What's the secret?

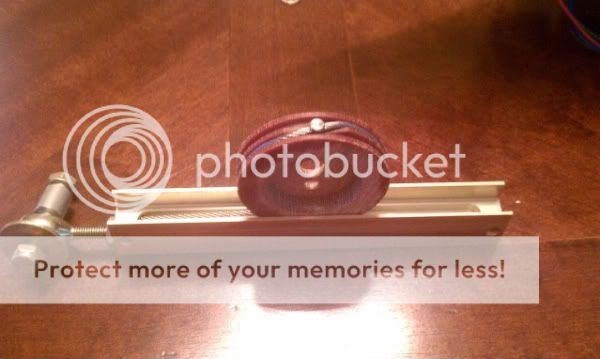

I know you have the threaded rod end bearing as adjustment, but what's the process to get it all adjusted and to reconcile any deviations in hole locate to the proper position on the servo?

I'm sure this is much simpler than I'm making it, but I'd like to know what I'm doing before doing it.

Thanks,

Phil

Also: I'm guessing I remove the locking nut that holds the wheel onto the servo so I can mount it through the bracket? Then reinstall after mounting it and safety wiring the bolts?

This is the hole where the bar attaches to the bell crank arm.

http://www.trutrakflightsystems.com/documents/RV10pitch.pdf

What's the secret?

I know you have the threaded rod end bearing as adjustment, but what's the process to get it all adjusted and to reconcile any deviations in hole locate to the proper position on the servo?

I'm sure this is much simpler than I'm making it, but I'd like to know what I'm doing before doing it.

Thanks,

Phil

Also: I'm guessing I remove the locking nut that holds the wheel onto the servo so I can mount it through the bracket? Then reinstall after mounting it and safety wiring the bolts?

Last edited: