Done!

Well, it had to happen eventually. This build is Done!

A few weeks ago, Tanya proclaimed "I just want this thing to be done! How will we ever know when it is finally finished?" Hmm, I can fix that. Here is a picture of her Christmas gift that she got Christmas morning.

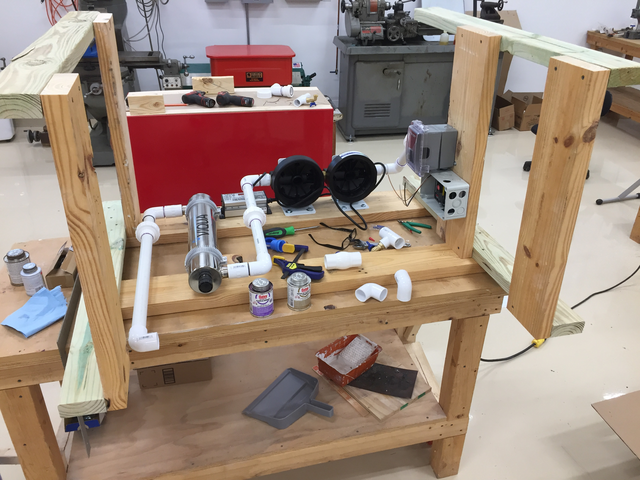

A couple of weeks ago, I finished building out the rainwater collection pump house equipment. I did most of the work comfortably up on a work bench then just moved full assemblies out.

We spent another full weekend moving, unpacking and organizing tools, airplane parts and all things shop from the house and the hangar. It is really great not to have tools in boxes piled up in closets in the house. All of the RV8 build parts have been moved back from the hangar and are all accessible. With all the reclaimed space in the house, we were even able to unpack more house stuff. We've been in this state of limbo for a little over a year since we moved here.

Tanya took a big pile of hardware store (non-flight) hardware and collapsed it into nice little bins. I don't have the patience for that kind of tedium but she does.

And then the big event. The day after Christmas, it was time to go get the -8 fuselage from the hangar (just a couple thousand feet from the shop)!

Three minutes later. Hip-hip-hurray! It is real now. Hey, check out that beautiful green rye grass that surrounds the shop. All of our friends said the obvious, "Ok, now get to work."

A few glamour shots. This was the end goal all along. Gee, I should have built it just a little bigger... I call this mood lighting. Only half of the lights on.

The airframe was covered in a nice layer of hangar dust which Tanya quickly dispatched with a damp rag while I marveled at the current state of affairs over a beer. Notice that she has a jacket on. I had the A/C cranking out 69 degrees. Yeah, we had a little Christmas heat wave.

I think that is the end of this little story. Let a new chapter begin. Standing over the -8 fuselage in the shop last night, "Let's see, where was I..."