Jim Kranich

I'm New Here

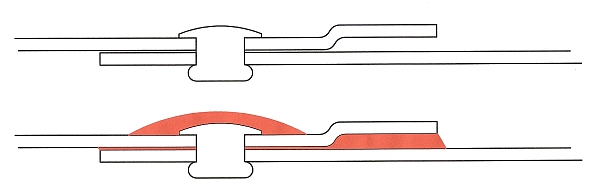

I've been flying my RV-7A for a year now and have just noticed about 10 rivets in the fuel tank are seeping fuel, causing a bubble in the paint around the rivet head. Most of the problem rivets are on the top side of the tank and a few on the bottom. Has anyone experienced this and if so, what's the best fix?

Jim

Jim