From the "picture is worth 1000 words" category, here are some shots of how I did my alternate induction air cable (IO-360-M1B, horizontal induction).

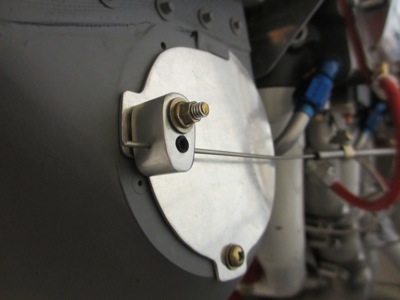

Instead of the plans method, I made little steel brackets and attached the cable sleeve to some handy sump bolts:

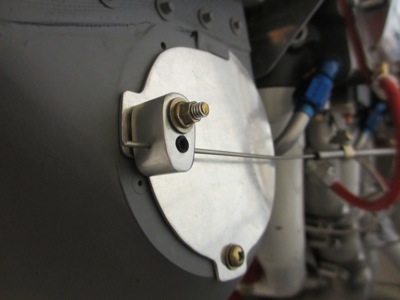

And instead of just winding the cable around a screw on the door, I made my own little custom aluminum cable anchor thingy on the mill. It pivots on a brass bushing and the cable wire is clamped between a pair of set screws, loctited in place. Same principle as the "B-nut" found elsewhere, just adapted for this particular application.

I had hoped to find a more elegant way to construct the door that would allow it to be both opened and closed with the cable, as some of you clever guys have done, but I decided not to spend any more time on it right now. Maybe on the next airplane.

Full blog entry: http://www.rv7blog.com/2013/11/04/alternate-air-cable/

Instead of the plans method, I made little steel brackets and attached the cable sleeve to some handy sump bolts:

And instead of just winding the cable around a screw on the door, I made my own little custom aluminum cable anchor thingy on the mill. It pivots on a brass bushing and the cable wire is clamped between a pair of set screws, loctited in place. Same principle as the "B-nut" found elsewhere, just adapted for this particular application.

I had hoped to find a more elegant way to construct the door that would allow it to be both opened and closed with the cable, as some of you clever guys have done, but I decided not to spend any more time on it right now. Maybe on the next airplane.

Full blog entry: http://www.rv7blog.com/2013/11/04/alternate-air-cable/

Last edited: