f14av8r

Well Known Member

Hi Guys,

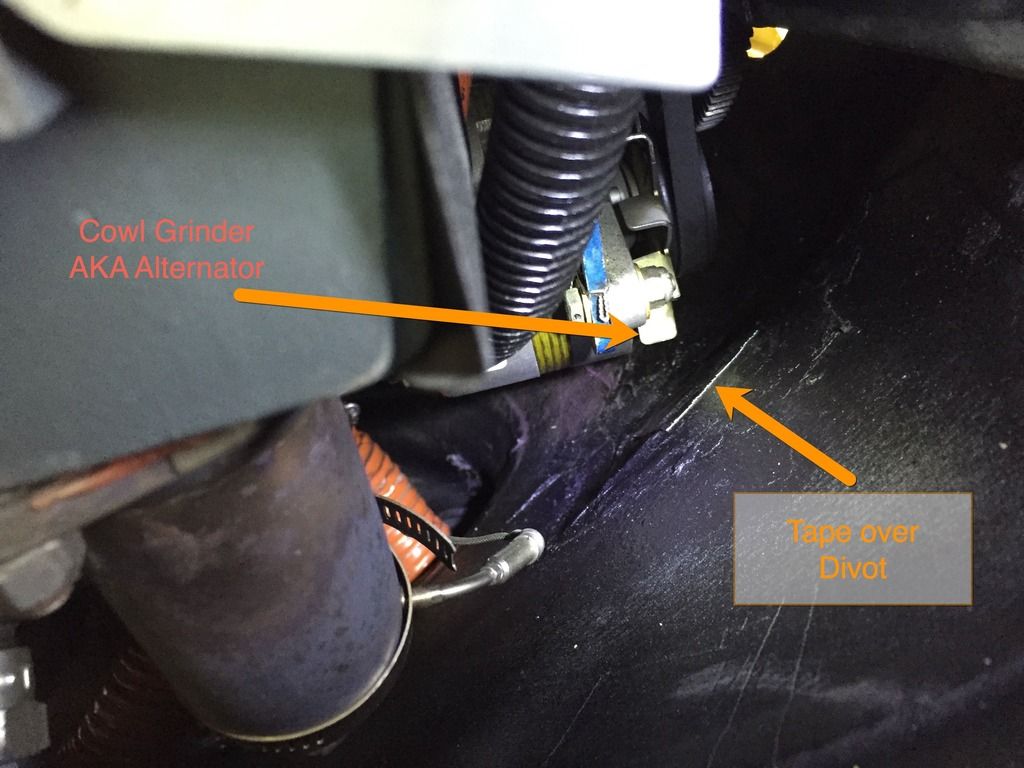

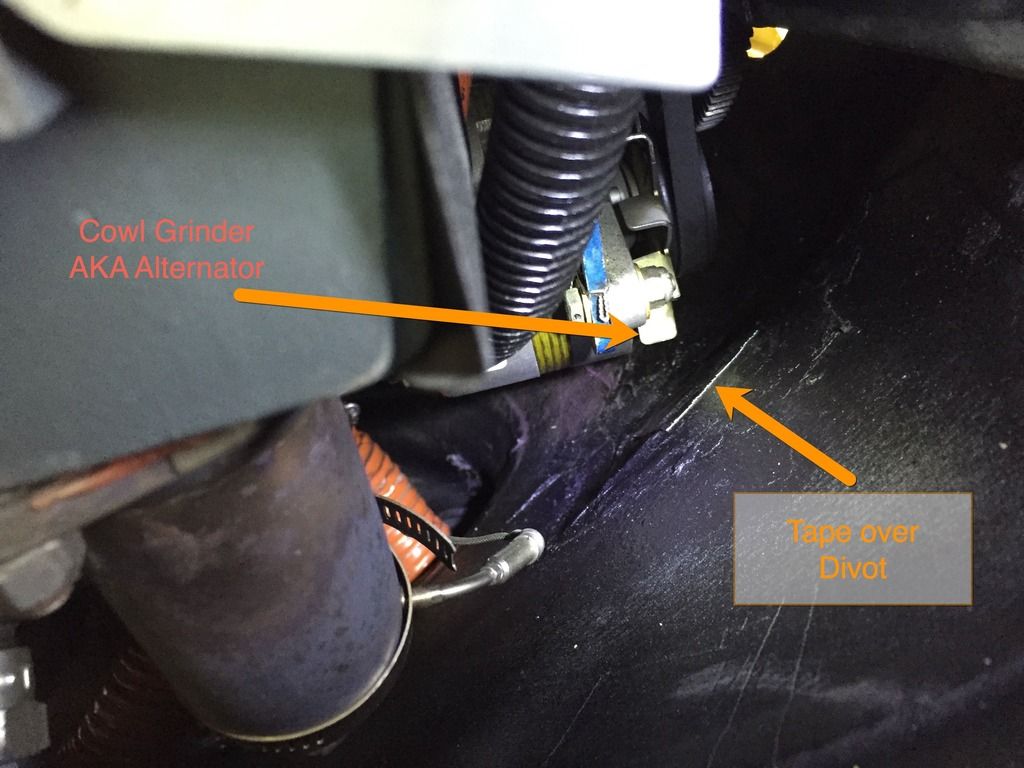

Need a little help here. After my 5th flight in my new (to me) RV-4, I noticed a small hole on the outside of the lower, right side of the cowl. When I took the cowl off, there was about a 2x1 by 1/2" deep divot in the cowl. I was obvious to me that the area had been repaired previously and I thought the previous repair had just let go. I taped over the hole and flew a few more flights while contemplating the repair.

A few days back, I filled the divot with epoxy and went flying. When I came back, I was surprised to find the hole was back and all my epoxy was cleanly removed from the divot. Slow on the uptake, I though I'd just failed to adequately clean the area and began contemplating another repair. I taped over the outside of the hole and kept flying.

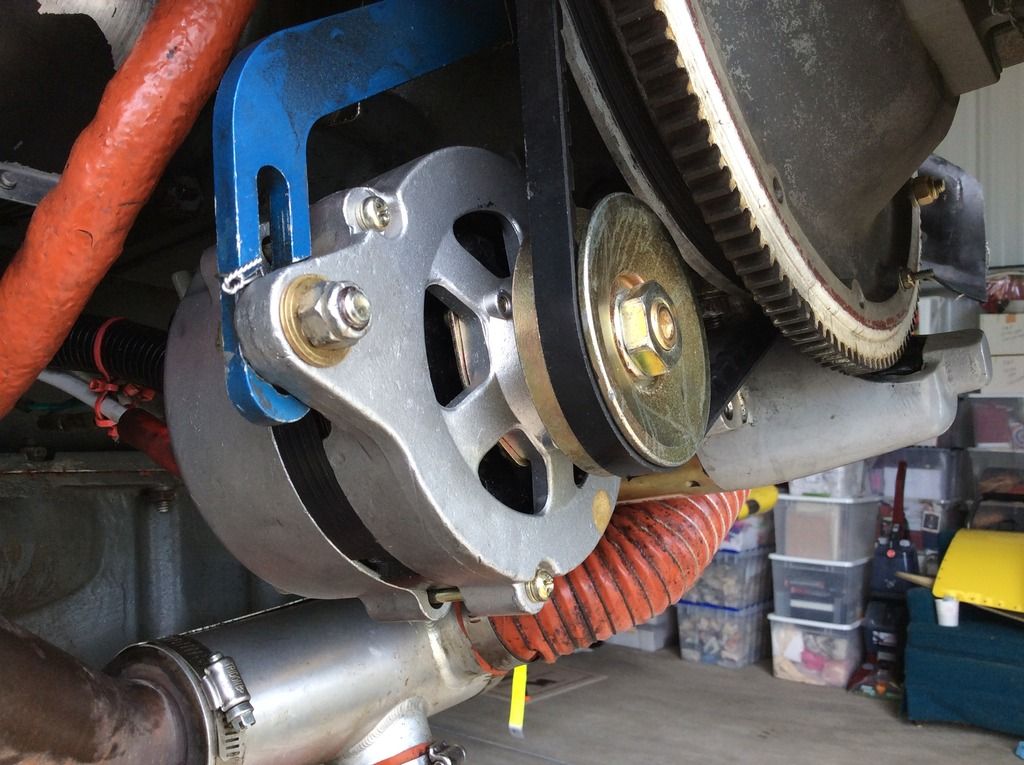

This morning, while re-cowling after some other work, I looked through the gap between the upper and lower cowl halves (piano hinge removed) and it instantly became clear that the divot is being caused by the alternator. That fan thing on the alternator is grinding away at my cowl!

I suspect the reason this hadn't become apparent earlier is because the previous owner wasn't flying the airplane as aggressively as I am. I'm regularly putting 4.5g on the airplane during aerobatics.

I attached a photo from the outside of the cowl, one of the divot from the inside of the cowl, and a photo through the cowl junction looking at the alternator. I put a piece of tape on the inside of the cowl over the divot. The white line visible in the photo is the edge of the tape covering the divot. I'm using the tape to confirm on my next flight that interference is still occurring but I'm about 90% sure that it is.

My questions for all you experts:

Is it normal for the engine to sag on the mount under "g" enough to cause this to happen?

What should I do to eliminate the alternator to cowl interference?

Thanks for the help!

Randy

Photo of cowl damage. The damage penetrated the cowl at this point.

Photo of divot from inside of cowl.

Photo of area through the right side of the upper / lower cowl junction

Need a little help here. After my 5th flight in my new (to me) RV-4, I noticed a small hole on the outside of the lower, right side of the cowl. When I took the cowl off, there was about a 2x1 by 1/2" deep divot in the cowl. I was obvious to me that the area had been repaired previously and I thought the previous repair had just let go. I taped over the hole and flew a few more flights while contemplating the repair.

A few days back, I filled the divot with epoxy and went flying. When I came back, I was surprised to find the hole was back and all my epoxy was cleanly removed from the divot. Slow on the uptake, I though I'd just failed to adequately clean the area and began contemplating another repair. I taped over the outside of the hole and kept flying.

This morning, while re-cowling after some other work, I looked through the gap between the upper and lower cowl halves (piano hinge removed) and it instantly became clear that the divot is being caused by the alternator. That fan thing on the alternator is grinding away at my cowl!

I suspect the reason this hadn't become apparent earlier is because the previous owner wasn't flying the airplane as aggressively as I am. I'm regularly putting 4.5g on the airplane during aerobatics.

I attached a photo from the outside of the cowl, one of the divot from the inside of the cowl, and a photo through the cowl junction looking at the alternator. I put a piece of tape on the inside of the cowl over the divot. The white line visible in the photo is the edge of the tape covering the divot. I'm using the tape to confirm on my next flight that interference is still occurring but I'm about 90% sure that it is.

My questions for all you experts:

Is it normal for the engine to sag on the mount under "g" enough to cause this to happen?

What should I do to eliminate the alternator to cowl interference?

Thanks for the help!

Randy

Photo of cowl damage. The damage penetrated the cowl at this point.

Photo of divot from inside of cowl.

Photo of area through the right side of the upper / lower cowl junction