Hi all,

I attended an EAA Webinar on fuel flow testing. The primary point was that you really want to make sure you know what your flows and unusable amounts are. They said that if you were using a known design, built to plans, it would be adequate to test in flight level only. Being the obsessive/compulsive I am, I decided that I should do the how series.

Materials and Methods:

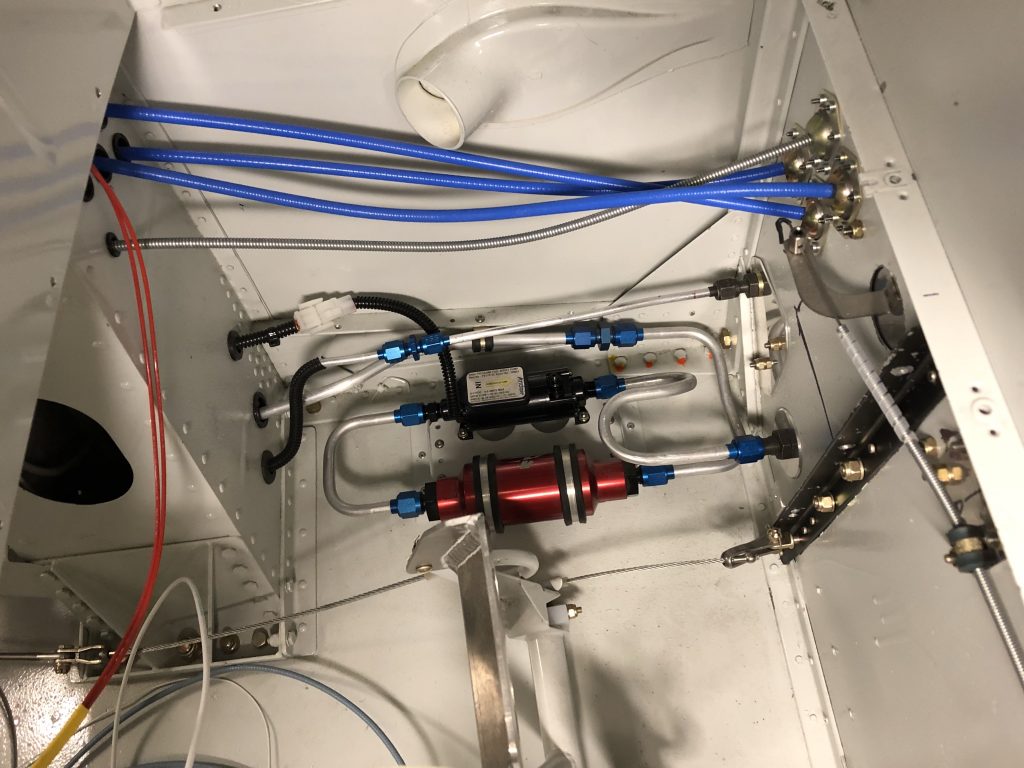

My plane is an RV8, not yet flown. IO360M1B. Airflow performance fuel pump and FI system.

I started by using a translucent white fuel can. I went to my local pump and filled it gallon by gallon, marking the levels on the outside to 4.5 gallons. Plastic and no ground made me a bit nervous. We had two people and a fire extinguisher at the ready during the test.

We poured the 4.5 gallons in the left tank. The fuel hose was disconnected from the engine pump and a hose fabricated to bring it back into the translucent fuel can. The plane was placed in flight level condition. I turned on the booster pump and then timed how long it took to pump each gallon of fuel. When it ran dry, I noted how much remained.

We then drained the remaining fuel back into the fuel can and repeated on the right side.

Next, we tilted the aircraft to 19 degrees down. That would be the angle at which it faced with my friend holding the tail wheel over his head. We repeated test. We reduced the angle to 10 degrees, noted the change in unusable fuel. The test was repeated at 11 degrees nose up (where it rests in a three point position) and at 19 degrees nose up, the best I could do with a ditch at the end of a ramp at our airport.

Results:

Timing the fuel flow and multiplying it out, here is what we found:

Flight Level

Left: 43.53 gal/hr about .3 gal unusable

Right: 29.4 gal/hr about .3 gal unusable

20 Degrees Nose Down

Left: 43.2 gal/hr about 3.5 gal unusable

Right: 29.1 gal/hr about 3 gal unusable

10 Degrees Nose Down

Left: Same flow, .9 gal unusable

Right: Same flow, 1.25 gal unusuable

11 Degrees Nose Up

Left: Same Flow, .2 gal unusuable

Right: Same Flow, .2 gal unusable

19 Degrees Nose Up

Left: Same Flow, .2 gal unusable

Right: Same Flow, .2 gal. unusable

Discussion:

I searched the archives, asked questions and even wrote Van's, trying to ascertain the correct angles to use for testing. 19 degrees nose down looked like a terrifying dive to me. 10 degrees will probably be an adequate benchmark for a normal approach. I just finished transition training with Mike Seager in Oregon. He used 10-12 degrees nose up as Vy. I hope someone will look at their EFIS in a Vx climb and verify that 20 degrees is reasonable.

The fuel flow was essentially identical at all angles. I think that is simply a function of the pump's capacity and the length and diameter of the fuel lines. The left tank has a considerably shorter length of fuel line between the tank and the selector. I believe that is the reason for the difference in the fuel flows left to right.

The interesting numbers are the unusable amounts. Flight level and nose up, they are really minimal. I wished I had had a quart measuring cup to get the numbers more exact, but the bottom line is that the tanks empty really well. The exception is nose down. The steeper the dive, the more likely to unport.

I felt a real sense of satisfaction after having completed this testing. The left tank flows at 2.7 times the maximal flow at full power (assuming 16 GPH, which seems to be the number I find most commonly here). The right flows at 1.8 times the maximum engine requirement. I think I saw the figure of 1.5 as being the desired minimum. Perhaps someone knows that figure? Assuming the above, fuel starvation should not be a problem on my first flight--assuming I remember to fill the tanks first.

Regards,

Michael Wynn

RV 8 Finishing

KLVK

I attended an EAA Webinar on fuel flow testing. The primary point was that you really want to make sure you know what your flows and unusable amounts are. They said that if you were using a known design, built to plans, it would be adequate to test in flight level only. Being the obsessive/compulsive I am, I decided that I should do the how series.

Materials and Methods:

My plane is an RV8, not yet flown. IO360M1B. Airflow performance fuel pump and FI system.

I started by using a translucent white fuel can. I went to my local pump and filled it gallon by gallon, marking the levels on the outside to 4.5 gallons. Plastic and no ground made me a bit nervous. We had two people and a fire extinguisher at the ready during the test.

We poured the 4.5 gallons in the left tank. The fuel hose was disconnected from the engine pump and a hose fabricated to bring it back into the translucent fuel can. The plane was placed in flight level condition. I turned on the booster pump and then timed how long it took to pump each gallon of fuel. When it ran dry, I noted how much remained.

We then drained the remaining fuel back into the fuel can and repeated on the right side.

Next, we tilted the aircraft to 19 degrees down. That would be the angle at which it faced with my friend holding the tail wheel over his head. We repeated test. We reduced the angle to 10 degrees, noted the change in unusable fuel. The test was repeated at 11 degrees nose up (where it rests in a three point position) and at 19 degrees nose up, the best I could do with a ditch at the end of a ramp at our airport.

Results:

Timing the fuel flow and multiplying it out, here is what we found:

Flight Level

Left: 43.53 gal/hr about .3 gal unusable

Right: 29.4 gal/hr about .3 gal unusable

20 Degrees Nose Down

Left: 43.2 gal/hr about 3.5 gal unusable

Right: 29.1 gal/hr about 3 gal unusable

10 Degrees Nose Down

Left: Same flow, .9 gal unusable

Right: Same flow, 1.25 gal unusuable

11 Degrees Nose Up

Left: Same Flow, .2 gal unusuable

Right: Same Flow, .2 gal unusable

19 Degrees Nose Up

Left: Same Flow, .2 gal unusable

Right: Same Flow, .2 gal. unusable

Discussion:

I searched the archives, asked questions and even wrote Van's, trying to ascertain the correct angles to use for testing. 19 degrees nose down looked like a terrifying dive to me. 10 degrees will probably be an adequate benchmark for a normal approach. I just finished transition training with Mike Seager in Oregon. He used 10-12 degrees nose up as Vy. I hope someone will look at their EFIS in a Vx climb and verify that 20 degrees is reasonable.

The fuel flow was essentially identical at all angles. I think that is simply a function of the pump's capacity and the length and diameter of the fuel lines. The left tank has a considerably shorter length of fuel line between the tank and the selector. I believe that is the reason for the difference in the fuel flows left to right.

The interesting numbers are the unusable amounts. Flight level and nose up, they are really minimal. I wished I had had a quart measuring cup to get the numbers more exact, but the bottom line is that the tanks empty really well. The exception is nose down. The steeper the dive, the more likely to unport.

I felt a real sense of satisfaction after having completed this testing. The left tank flows at 2.7 times the maximal flow at full power (assuming 16 GPH, which seems to be the number I find most commonly here). The right flows at 1.8 times the maximum engine requirement. I think I saw the figure of 1.5 as being the desired minimum. Perhaps someone knows that figure? Assuming the above, fuel starvation should not be a problem on my first flight--assuming I remember to fill the tanks first.

Regards,

Michael Wynn

RV 8 Finishing

KLVK