jay.pearlman

Well Known Member

I have an RV6A which was completed this year and recently started flying, with about 40 hours now. The aircraft has an IO360M1B, uses the engine mount and isolators supplied with the kit, and a Hartzell constant speed prop. I hung the engine on the mounts and isolators for about two years before putting the engine and mount on the firewall. Everything looked fine. But maybe it wasn't so.

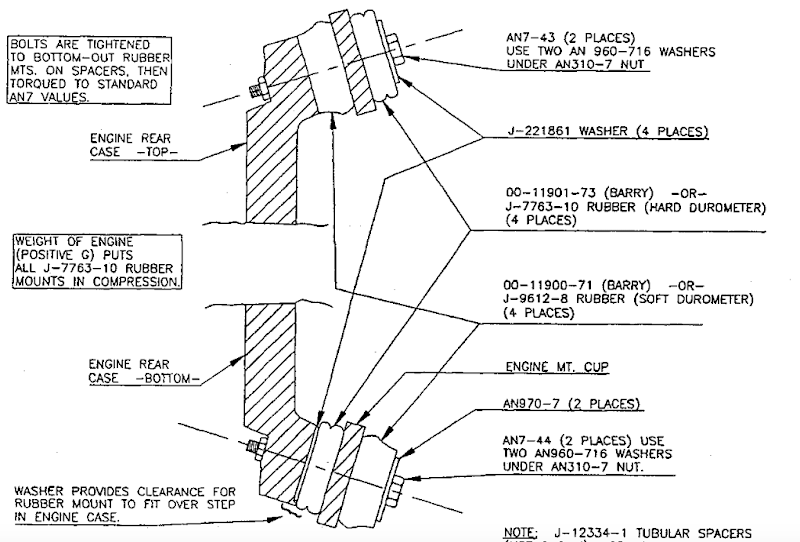

Yesterday, I was looking at the engine and the mount and the rear of the oil sump is rubbing on the engine mount tubing. The installation was done according to plans, although the isolators have different characteristics for the inside and out and may have been reversed?

I was thinking about isolators and perhaps some spacers. However, I would not have expected interference on factory built (mount and engine) components.

Any suggestions?

Yesterday, I was looking at the engine and the mount and the rear of the oil sump is rubbing on the engine mount tubing. The installation was done according to plans, although the isolators have different characteristics for the inside and out and may have been reversed?

I was thinking about isolators and perhaps some spacers. However, I would not have expected interference on factory built (mount and engine) components.

Any suggestions?

Last edited: