We've seen or heard of several incidences of fuel filter contamination recently now and present some photos and information with what we've learned so far.

In all cases, the filters are 40 micron SS mesh type.

Photo 1 is a pre-pump filter showing 'normal' construction debris. 100LL fuel USA.

Photo 2 is a post filter showing the dark goo others have reported. 100LL fuel USA.

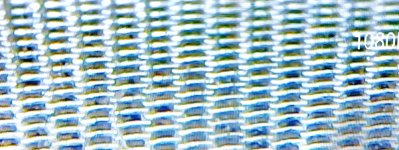

Photo 3 is a pre-pump filter showing microbial contamination (lab determined to be aerobic and anaerobic). Mogas fuel. Spain.

We are not sure what the plugging medium is in the second photo or those involved from other reports or observations, usually dark in color.

It seems that water present in the fuel during storage on in the aircraft tanks can precipitate microbe growth. Ethanol may also add an oxygen component that facilitates growth of certain bacteria strains.

One may consider a biocide developed for aviation such as Biobor: https://www.biobor.com/products/biobor-jf-aviation/

We have seen at least two incidents with the post filter contaminated but not the pre-pump filter so there are still some unanswered questions.

I'll post more info as we learn more.

In all cases, the filters are 40 micron SS mesh type.

Photo 1 is a pre-pump filter showing 'normal' construction debris. 100LL fuel USA.

Photo 2 is a post filter showing the dark goo others have reported. 100LL fuel USA.

Photo 3 is a pre-pump filter showing microbial contamination (lab determined to be aerobic and anaerobic). Mogas fuel. Spain.

We are not sure what the plugging medium is in the second photo or those involved from other reports or observations, usually dark in color.

It seems that water present in the fuel during storage on in the aircraft tanks can precipitate microbe growth. Ethanol may also add an oxygen component that facilitates growth of certain bacteria strains.

One may consider a biocide developed for aviation such as Biobor: https://www.biobor.com/products/biobor-jf-aviation/

We have seen at least two incidents with the post filter contaminated but not the pre-pump filter so there are still some unanswered questions.

I'll post more info as we learn more.

Attachments

Last edited: