Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Accidental Destruction Anti-Splat

- Thread starter PerfTech

- Start date

What damage has been done to parts above the landing gear? How do you plan to check that out? I mean, in all seriousness, who cares about the wheel pants or transition fairings? What other structural damage has been done? So far the landing gear and everything below is ruined, What has been damaged above?!?!

.

.

Last edited:

PerfTech

Well Known Member

Great News for Us!!!!!!!

... We just finished up with the inspection of the entire aircraft last night and am very happy to say this is an extremely well built, bullet proof airplane. We removed all inspection covers, tanks, horizontal stabilizer, vertical stabilizer and all mountings, bulkheads, floor, spars and carry through assembly, all controls and associated parts, engine mount, gear weldments and mountings. Everything looks like new and all damage was confined to the gear, tires, wheels and wheel pants. We are reassembling today with all new undamaged parts and should be back in the air this weekend, (less wheel pants that are in our paint shop). This really speaks volumes to the quality of design and construction of these wonderful little airplanes. Just imagine the nightmare, time involved, paper work, lack of availability of parts and insane costs involved if this were to happen with a factory built spam-can. All I can say is "I LOVE MY RV" and have very little desire to own anything else Thanks, Allan...

... We just finished up with the inspection of the entire aircraft last night and am very happy to say this is an extremely well built, bullet proof airplane. We removed all inspection covers, tanks, horizontal stabilizer, vertical stabilizer and all mountings, bulkheads, floor, spars and carry through assembly, all controls and associated parts, engine mount, gear weldments and mountings. Everything looks like new and all damage was confined to the gear, tires, wheels and wheel pants. We are reassembling today with all new undamaged parts and should be back in the air this weekend, (less wheel pants that are in our paint shop). This really speaks volumes to the quality of design and construction of these wonderful little airplanes. Just imagine the nightmare, time involved, paper work, lack of availability of parts and insane costs involved if this were to happen with a factory built spam-can. All I can say is "I LOVE MY RV" and have very little desire to own anything else Thanks, Allan...

BSwayze

Well Known Member

... We just finished up with the inspection of the entire aircraft last night and am very happy to say this is an extremely well built, bullet proof airplane. We removed all inspection covers, tanks, horizontal stabilizer, vertical stabilizer and all mountings, bulkheads, floor, spars and carry through assembly, all controls and associated parts, engine mount, gear weldments and mountings. Everything looks like new and all damage was confined to the gear, tires, wheels and wheel pants. We are reassembling today with all new undamaged parts and should be back in the air this weekend, (less wheel pants that are in our paint shop). This really speaks volumes to the quality of design and construction of these wonderful little airplanes. Just imagine the nightmare, time involved, paper work, lack of availability of parts and insane costs involved if this were to happen with a factory built spam-can. All I can say is "I LOVE MY RV" and have very little desire to own anything else Thanks, Allan...

Allan, you have absolutely made my day with this news. It reaffirms my decision to build an RV-7A more than ever! Thank you so much for getting back to us and reporting on your inspection results! I have already had my nosewheel mod done by you, and I will definitely be placing an order for the nose job support package before this plane flies.

Please continue to update us as you get these parts replaced, and any further information and developments, as they occur. Pictures, please! Thanks so much for all you have done for the RV community.

PerfTech

Well Known Member

Have a little more info of possible interest!!!!

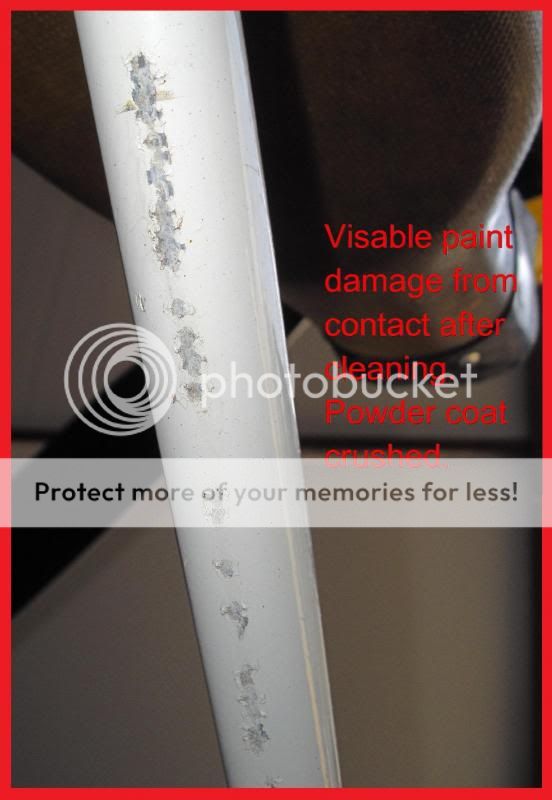

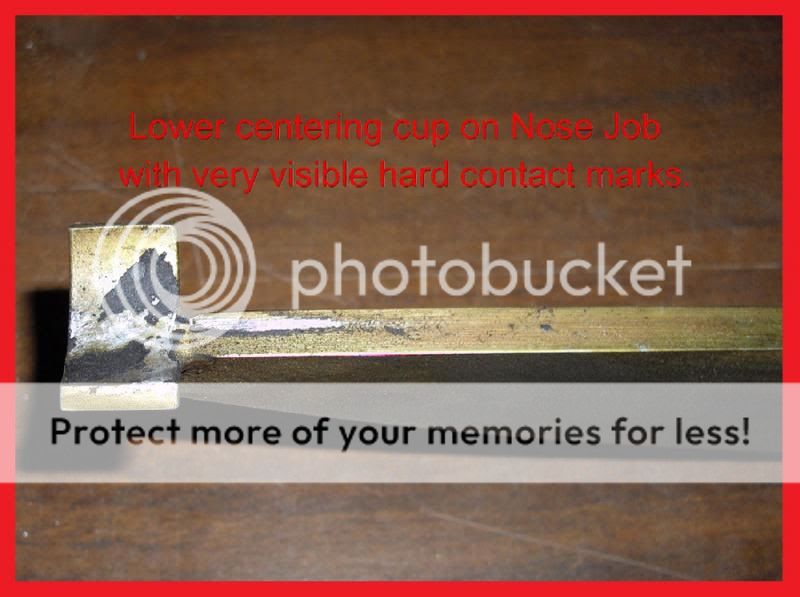

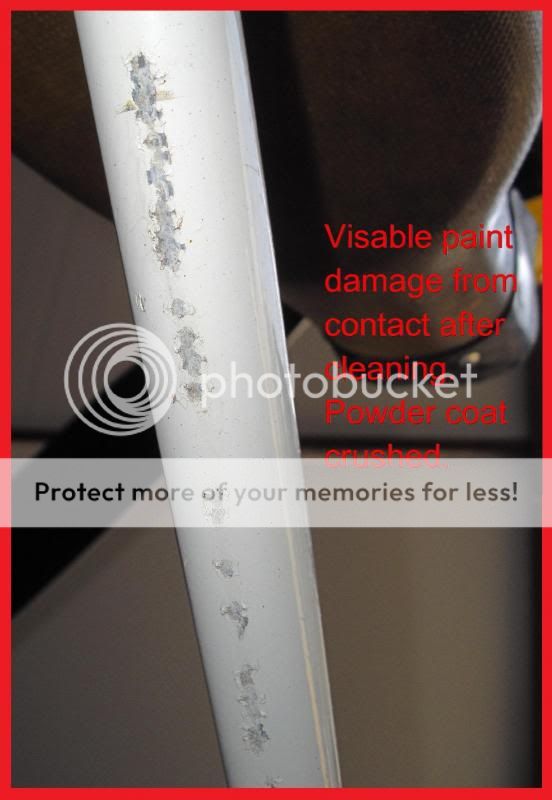

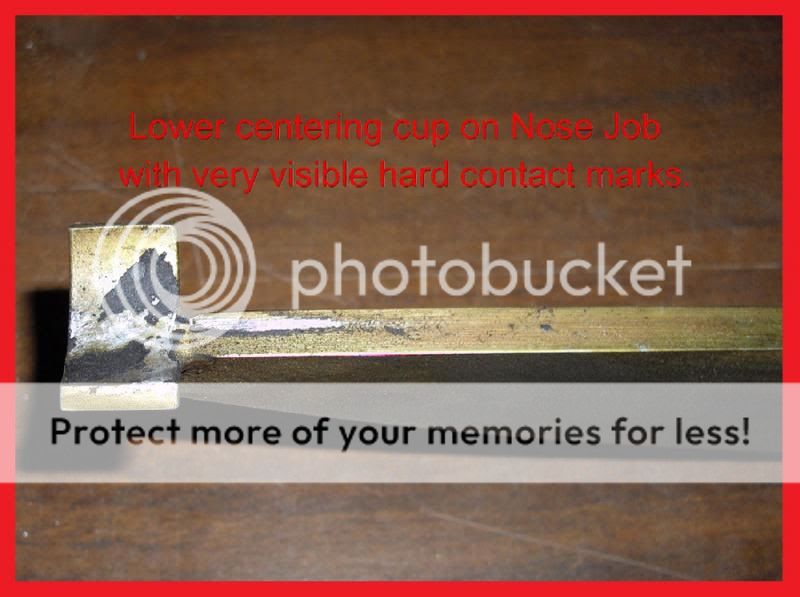

... During our inspection and repairs I took a few more photos that may or my not be of interest. I removed "The Nose Job" and had a good look at it and the back side of the nose gear leg. The very hard and aggressive contact that obviously took place left witness marks the entire length of the Nose Job. Everything was straight as an arrow, but you can plainly see it really saw some serious action. The photos below are pretty much self explanatory. I feel they show at the least, the Nose Job played a significant roll in this event. We completed our re-assembly today and I flew my plane this evening. It flies wonderfully just like always, just a little slower without the wheel pants (in our paint shop) installed. Should have them finished in a few days. Regards all, Allan...

.

.

.

.

.

.

.

... During our inspection and repairs I took a few more photos that may or my not be of interest. I removed "The Nose Job" and had a good look at it and the back side of the nose gear leg. The very hard and aggressive contact that obviously took place left witness marks the entire length of the Nose Job. Everything was straight as an arrow, but you can plainly see it really saw some serious action. The photos below are pretty much self explanatory. I feel they show at the least, the Nose Job played a significant roll in this event. We completed our re-assembly today and I flew my plane this evening. It flies wonderfully just like always, just a little slower without the wheel pants (in our paint shop) installed. Should have them finished in a few days. Regards all, Allan...

.

.

.

.

.

..

David-aviator

Well Known Member

OK so the damage is minimal and a visual inspection says that the airframe will soon be ready to go back into service. All good news.

Now the question is did the airframe and crew experience 5-1/5 g's as indicated on the Acceleration instrument or something lower or much higher? Based on the reported damage perhaps it would be prudent to understand the dynamics of the g meter before the information displayed is used in drawing conclusions about the margin. of safety in the design.

I for one do not know the characteristic response of this particular instrument to what was probably a relatively short shock impulse when the landing gear contacted the runway. We typically evaluate the area under a shock envelope (amplitude and period) in order to determine the amount of energy that would have been dissipated into the airframe, or any other structure, in an event such as this. Peak g's as measured by an accelerometer without knowledge of the period over which the acceleration was present do not tell us much. In my business we measure shock impulses with a magnitude of over 1500 g's that have a duration less than two milliseconds that do no damage. On the other hand if we see a sustained impact acceleration over 4 g's for more than a few hundred milliseconds we know that we should scrap the test article as it has probably sustained permanent deformation or structural damage. This may or may not be the case here but using a mechanical g meter to draw any kind of conclusion(s) may lead to problems.

Yes tires were deformed, wheels were distorted, landing gear components may have been permanently deformed. Question is. Is that the extent of the damage?

My point is that if the value indicated on the g meter which is intended to respond over maneuvers lasting many fractions of a second or seconds indicates a value from an event and the actual event from the description was apparently very short in duration should the conclusion that the point be considered in the assessment of the damage to the airframe?

Quote from Alan's original post -

"This 5 1/2 gs translates (With the loading we had) to approximately 9,900 lb on the three gear legs."

I personally believe that this conclusion was at best premature and at worst may lead to returning an airframe to service prematurely. On the other hand perhaps the potential danger lies in the use of this value by others in evaluating the design margins of the RV-9a airframe and potentially making a bad decision down the road. This could include "There is a lot of margin in the design based on Alan's analysis and my aircraft will never be operated at those extremes so it will be OK to lighten up some of the structure."

Not saying that Alan is right or wrong just saying that it may be worthwhile to look at the big picture before jumping to conclusions.

Phil,

Your observation is interesting but not applicable at this level of activity.

To base a decision to return to service on the unknown characteristics of the G meter is taking the matter into an area beyond what is practical. Consider such an event without the G meter - there have been many in general aviation over the years and procedures have evolved to resolve such matters.

The standard practice is to inspect the airframe for cracks, bending or damage and make a decision, based on what is observed, to repair or junk the airplane. Allan was thorough in disassembling and inspecting the airplane, the decision to return to service is reasonable.