Desert Rat

Well Known Member

Hi All-

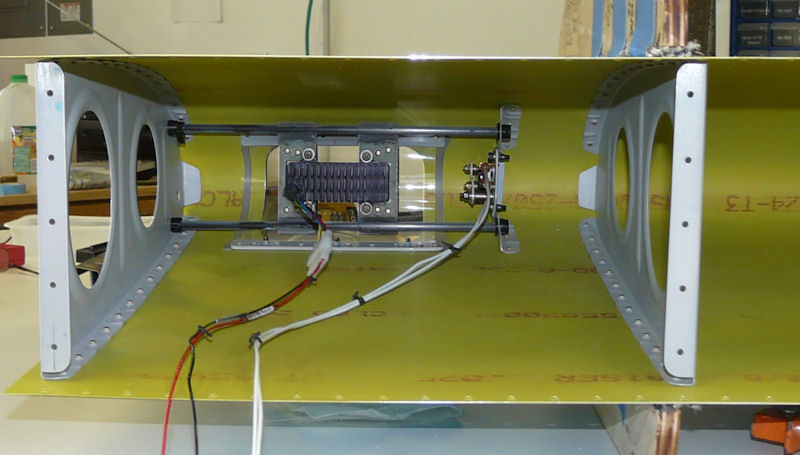

Does anybody know how thick the sheet metal is on the duckworks (or similar) leading edge landing light kit? I'm talking about the aluminum sheet stock that spans rib to rib that the lights actually get mounted on.

I've got some .025 scrap that I'm looking to put to good use and could just roll my own, but not sure if it needs to be a little more robust for vibration and whatnot.

Thanks,

Terry

Does anybody know how thick the sheet metal is on the duckworks (or similar) leading edge landing light kit? I'm talking about the aluminum sheet stock that spans rib to rib that the lights actually get mounted on.

I've got some .025 scrap that I'm looking to put to good use and could just roll my own, but not sure if it needs to be a little more robust for vibration and whatnot.

Thanks,

Terry