N546RV

Well Known Member

Abstract: I think this is my first real experience with the old saw about adding countless hours with an apparently simple divergence from the instructions. Instead of ordering throttle quadrants from Van's (along with the rear throttle kit), I ordered the quads from Spruce and decided to work out the linkage details myself. That only took, oh, about two weeks, since I had to figure out passthrough hole locations and how to mark them all on my own.

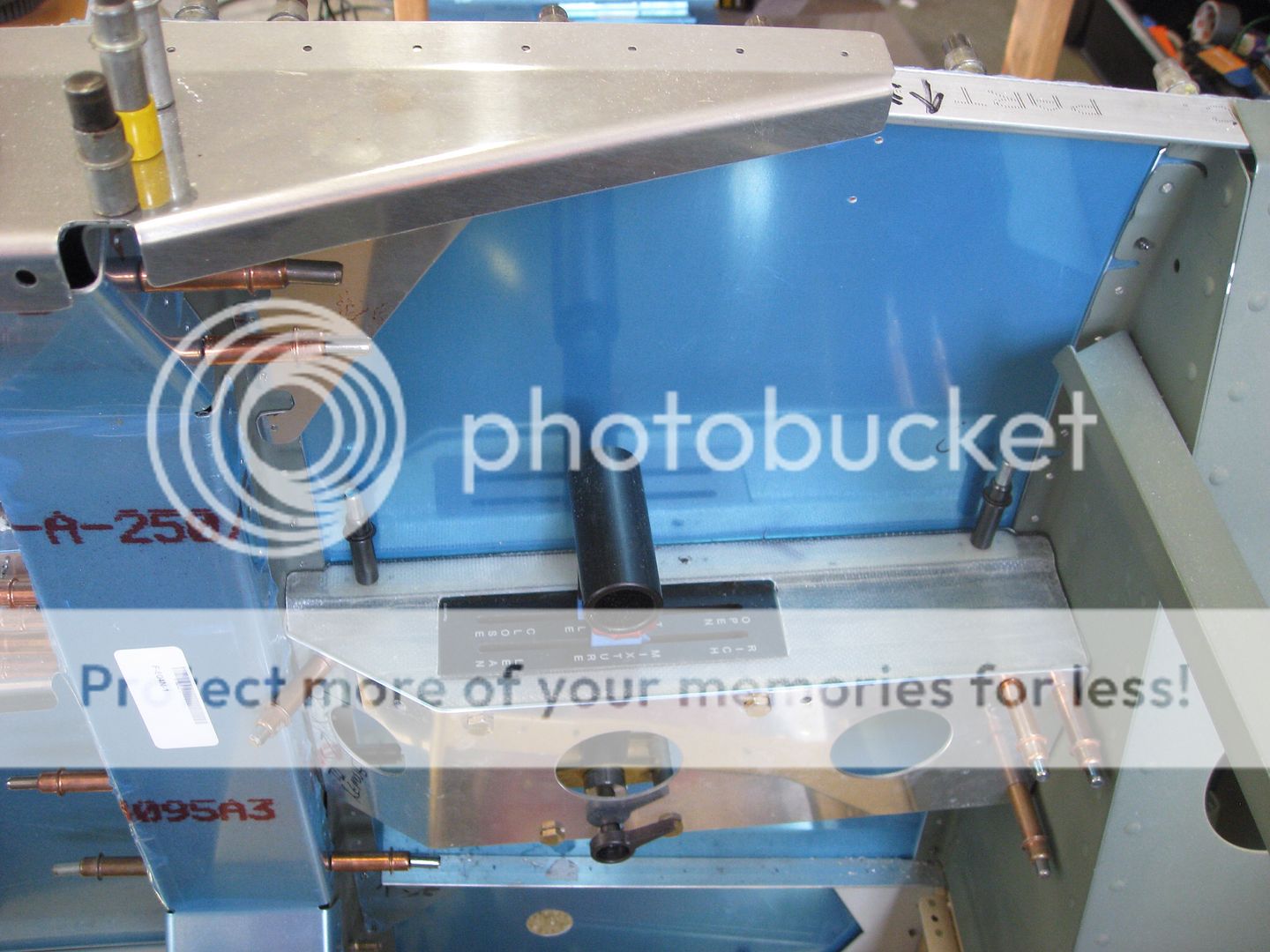

But I finally got that done, and as a final bit to put this throttle stuff away for awhile, I fabbed up a custom top cover plate for the forward throttle. This was kind of necessary, since the cutout in the factory plate is way too big for my two-lever quadrant. Looks nice, though!

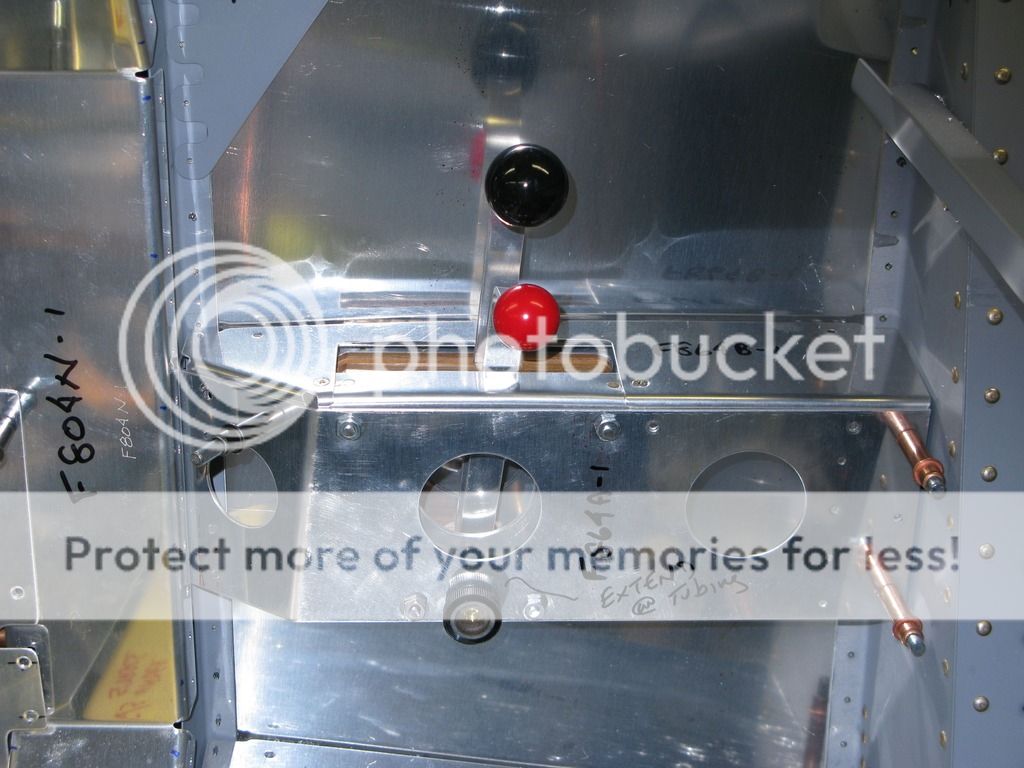

All that was left was to drill the screw holes to attach my cover plate to the outboard mount angle. I was going to use the factory plate as a template to help with this, so I clecoed it in place, only to find - uh-oh - that it inexplicably sits about 1/4" higher than the top of my quadrant. Which in turn means that the outboard angle sits above my nice cover plate.

To begin with, I'm befuddled by this. How was this factory cover ever supposed to took decent in the first place? The mount holes for the quadrant were predrilled, no way to mount it any higher. The "stock" quadrants don't look any taller than this deluxe model.

But that's just griping. The more important question is what to do. Since the holes in the forward side skin are prepunched for this mount angle, it's not a simple matter to just move the thing down. I think I might be able to fab up a new angle and have it work, but I'm skeptical that the rivet holes are going to end up too close to the inside of the angle. At best, setting the shop head will be difficult, and at worst, it'll be impossible to dimple the piece. But that's still going to be my plan A tomorrow night.

Another idea I had was to fabricate a new angle piece that just rivets to the flanges of the center section bulkhead and gear tower. Then I could just fill the rivet holes in the skin with NAS1097 rivets or something. But I'm not sure if that angle has an important job to do stiffening the skin in this area; for that matter, the skin might flex enough for those rivet shop heads to contact my angle piece and cause issues. It would also make things generally tighter when it came time to attach linkages and control cables.

I could fabricate a new cover plate and add a joggle at the outboard edge to allow it to use the factory angle mount, but I'd rather not remake that part, and I think this would look kind of ghetto anyway.

Raising the quadrant itself in any way seems like a non-starter, since I already have my passthrough holes for the rear throttle linkage cut. Plus it'd basically require me to fabricate a new throttle mount, which would be distinctly not-fun.

I dunno, I don't have any really good ideas how to proceed here. I might just be overthinking this, and forming my own angle will work fine and it'll be done. It wouldn't be the first time I worried myself sick over something and then took care of it in half an hour or something.

Any other thoughts on potential solutions here? Has anyone else run into this issue or something like it?

But I finally got that done, and as a final bit to put this throttle stuff away for awhile, I fabbed up a custom top cover plate for the forward throttle. This was kind of necessary, since the cutout in the factory plate is way too big for my two-lever quadrant. Looks nice, though!

All that was left was to drill the screw holes to attach my cover plate to the outboard mount angle. I was going to use the factory plate as a template to help with this, so I clecoed it in place, only to find - uh-oh - that it inexplicably sits about 1/4" higher than the top of my quadrant. Which in turn means that the outboard angle sits above my nice cover plate.

To begin with, I'm befuddled by this. How was this factory cover ever supposed to took decent in the first place? The mount holes for the quadrant were predrilled, no way to mount it any higher. The "stock" quadrants don't look any taller than this deluxe model.

But that's just griping. The more important question is what to do. Since the holes in the forward side skin are prepunched for this mount angle, it's not a simple matter to just move the thing down. I think I might be able to fab up a new angle and have it work, but I'm skeptical that the rivet holes are going to end up too close to the inside of the angle. At best, setting the shop head will be difficult, and at worst, it'll be impossible to dimple the piece. But that's still going to be my plan A tomorrow night.

Another idea I had was to fabricate a new angle piece that just rivets to the flanges of the center section bulkhead and gear tower. Then I could just fill the rivet holes in the skin with NAS1097 rivets or something. But I'm not sure if that angle has an important job to do stiffening the skin in this area; for that matter, the skin might flex enough for those rivet shop heads to contact my angle piece and cause issues. It would also make things generally tighter when it came time to attach linkages and control cables.

I could fabricate a new cover plate and add a joggle at the outboard edge to allow it to use the factory angle mount, but I'd rather not remake that part, and I think this would look kind of ghetto anyway.

Raising the quadrant itself in any way seems like a non-starter, since I already have my passthrough holes for the rear throttle linkage cut. Plus it'd basically require me to fabricate a new throttle mount, which would be distinctly not-fun.

I dunno, I don't have any really good ideas how to proceed here. I might just be overthinking this, and forming my own angle will work fine and it'll be done. It wouldn't be the first time I worried myself sick over something and then took care of it in half an hour or something.

Any other thoughts on potential solutions here? Has anyone else run into this issue or something like it?