Actually, I think that one has been discarded in favor of a better one.

Dan is correct

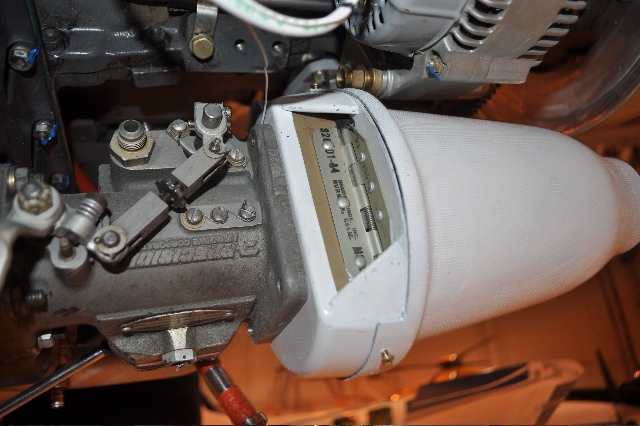

The snorkel shown in the photo was the early prototype / hybrid made by modifying the original that had been used with the RSA servo that was on the original 390A engine.

It was used for the initial flight testing of the new engine installation until the work was done to tweak the design for making production tooling.

It was at that point things started getting interesting.

We have have a reasonably good understanding of what makes good shapes when efficient movement of air is involved.

Very small tweaks were made to the shape (when compared to the original hybrid version that was used initially) while the final tooling was being made.

That snorkel was installed and everything was great, until we discovered a specific power range/flight condition where the engine was not happy at all.

This shape had very little difference from the current part that everyone is flying on the RSA style injection systems, but it was not working with the AFP.

Don and engineering at Lycoming worked hard to help but but were sure we had some type of ignition problem based on how it was acting. Long story short, we eventually came around to the realization that it was the snorkel. Don tested if for us on his flow bench and said it was horrible

Here is the interesting part..... at some point I discovered that if the (new) cowl flap was open, the engine ran fine. Close the cowl flap and the engine would start its die, run, die, run, cycle.

So just the small amount of pressure change across the inlet filter because of the change in upper plenum pressure with the cowl flap movement, was apparently having a noticeable effect on the inlet flow to the servo.

Redesigned the snorkel to have a very generous turn radius in the inlet run to the servo, and the problem was solved. We had Don test the final version as well and he said it flows very efficiently.

A side note top this (that I almost hate to mention so keep in mind it is just a single data point that was obtained during some other flight testing without any structured test plan).

While doing some flight testing at a dry lake bed (think miles and miles of smooth flat landing area) we did an impromptu test of the induction system by noting the MP value on the EFIS at ground level and then doing a flat out WOT run over the desert at 10 ' AGL. The in flight MP indication was a delta of +0.9 inches (0.9 " of ram air MP boost).

We are not prepared to officially promote this as part of the new design and we have no data for the old version to compare it too, but it is conceivable that closing down the outlet flow on the cowl in high speed flight will help with induction pressure since the inlet filter is inside the pressure plenum.

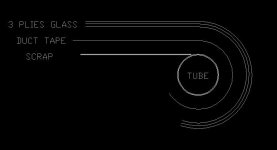

Here is a couple of photos of the final version prototype of the AFP snorkel.

Note the generous turn radius (about the same radius as the inlet to the servo). It may be difficult to copy this because the new RV-14 bottom cowl was reshaped ahead of the servo to give some additional room, but you should try and copy this to what every degree is possible. Note the photos are of the snorkel taped together after it had been cut in two to use it as a tool for making production tooling. Hopefully they will be useful.

The first is a view straight down from above showing the turn radius. The second looking directly fwd. from the servo side (but upside down). Hopefully they will be useful to those that are doing a DIY snorkel.