William Slaughter

Well Known Member

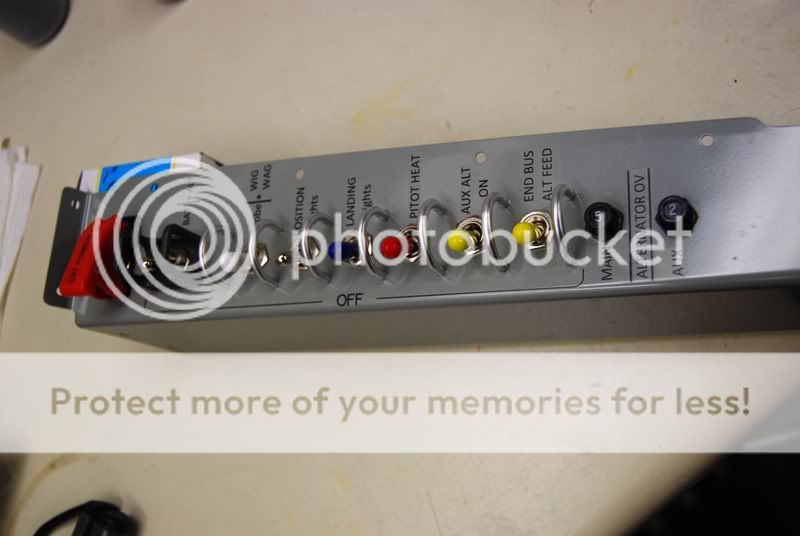

The DecalPro system has been discussed here in the past, with mixed reviews, but I'd decided that it was worth a try and purchased the setup some few months ago. The ability to produce white text labels for the dark instrument panel was the goal. Today I finally sat down to give it a test run, and can report excellent results. First I did one of the supplied test images in a nice red metallic foil, and it came out perfectly. I then printed out the text for the annunciator lights for the Gretz heated pitot in white, and ran it through the process with no problems. Two for two, right off the bat! Here is the annunciator image applied to a dummy test piece:

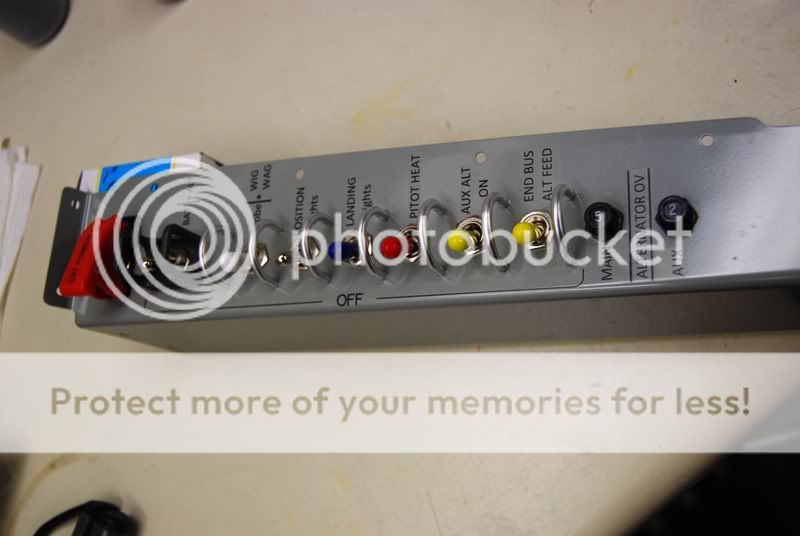

Since the text was black, I did the switch console with DIY water-slide decals with good results, but I'm sticking to the DecalPro system from here on out.

Since the text was black, I did the switch console with DIY water-slide decals with good results, but I'm sticking to the DecalPro system from here on out.