I was thinking that my RV-4 is within a couple of weeks or so of being ready to fly after its makeover. Unfortunately, I've hit a snag that could delay me. After 13 months without a flying airplane this smarts a bit.

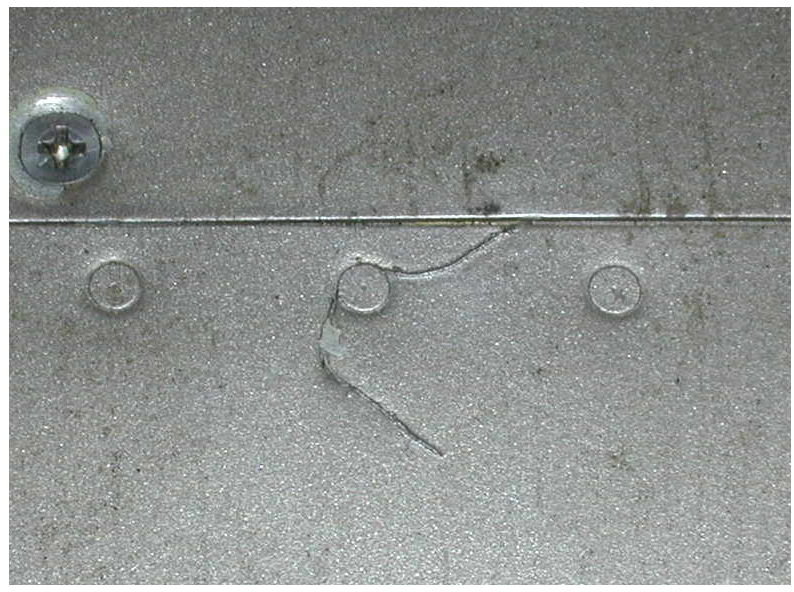

I found this wing crack on my top right wing skin just behind the tank:

Anyone seen a crack like this on an RV before? I'm guessing I'll need to add a doubler plate but it's the details that are stumping me. What thickness? How big? Do I drill out the existing rivets into the spar and re-rivet the doubler through those holes? There's no backside access so I guess I'll need to use pulled rivets; but which ones? And so on...

Thanks in advance.

Kev

I found this wing crack on my top right wing skin just behind the tank:

Anyone seen a crack like this on an RV before? I'm guessing I'll need to add a doubler plate but it's the details that are stumping me. What thickness? How big? Do I drill out the existing rivets into the spar and re-rivet the doubler through those holes? There's no backside access so I guess I'll need to use pulled rivets; but which ones? And so on...

Thanks in advance.

Kev