Clouddancer

Well Known Member

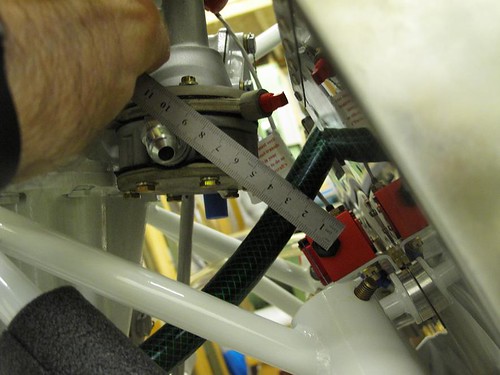

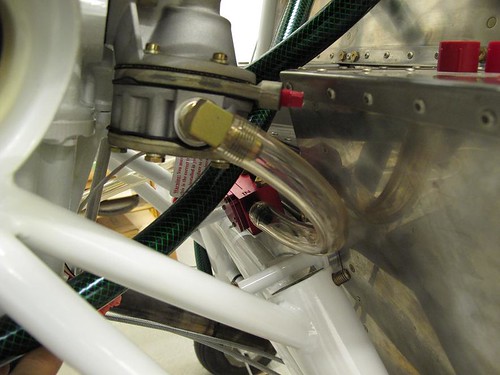

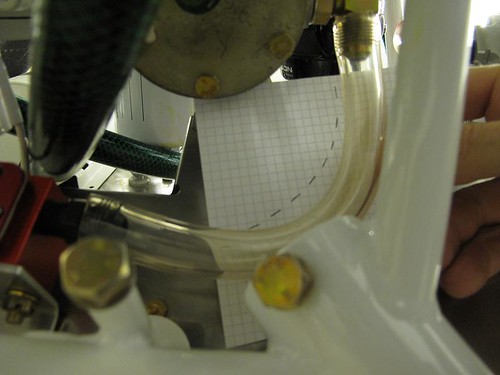

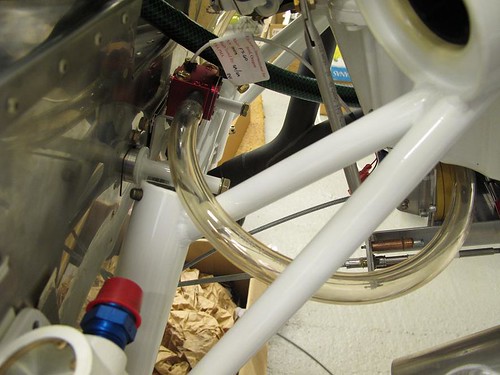

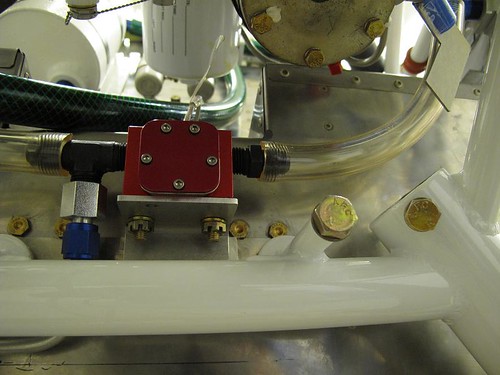

Background: I would like to use integrally sleeved Teflon hosed FWF on our RV-4. Those are Aeroquip AE466-6, Stratoflex 124-6J or similar hose from Titeflex. All those hoses have a minimal bending radius of 4.0?. I have foreseen to place the fuel flow sender on the firewall between the engine driven fuel pump and the carburator, resp. throttle body injector. The available space FWF on the RV-4 is marginal, especially if I want to place the fuel lines as far away as possible from the exhaust stacks. I came up with solutions that would require a bend radius of 2.5?. I also tried around with different angled fittings. But I still require the 2.5? radius. A possibility is to use non Teflon hose for that part of the fuel line. Those have smaller minimum bend radii. But that?s not the preferred solution.

I have seen that the high pressure (rated 3000psi) variants of above hoses (Aeroquip AE446-6, Stratoflex 171-6J) have a minimum bend radius of 2.5?. Has someone used them FWF? Or perhaps someone has another idea how to solve my dilemma?

I have seen that the high pressure (rated 3000psi) variants of above hoses (Aeroquip AE446-6, Stratoflex 171-6J) have a minimum bend radius of 2.5?. Has someone used them FWF? Or perhaps someone has another idea how to solve my dilemma?