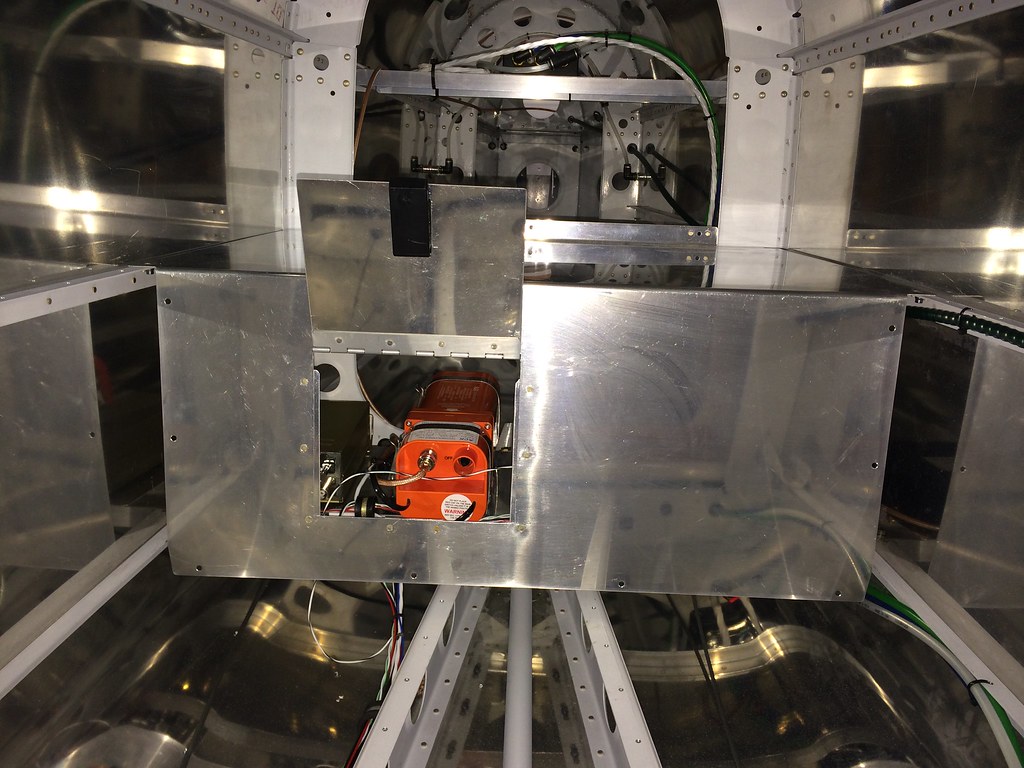

I hate removing the rear bulkhead and baggage compartment floor over the battery in my RV8. It?s truly a pain to get in there and remove all those screws as I am sure all 8 owners are aware. I have been pondering a solution and a thought occurred to me but I would like so feedback from the forum before I proceed. My plan is as follows:

My assumption is that these are non-structural components therefore I plan to remove the bulk head and stepped floor panel. Attach the bottom of the rear bulkhead to the floor panel with a hinge as used in the other locations on the aircraft. Replace the two top screws for the rear bulkhead with quarter turn fittings. Install 6 (estimated) flush latches, three per side (two on the each side of the upper deck and one on each side of the vertical part of the floor panel.

This should make the assembly removable simply by releasing the quarter turn fittings, folding the bulk head forward, and releasing the flush latches on each side of the floor and removing.

Does anyone see a fatal flaw in this?

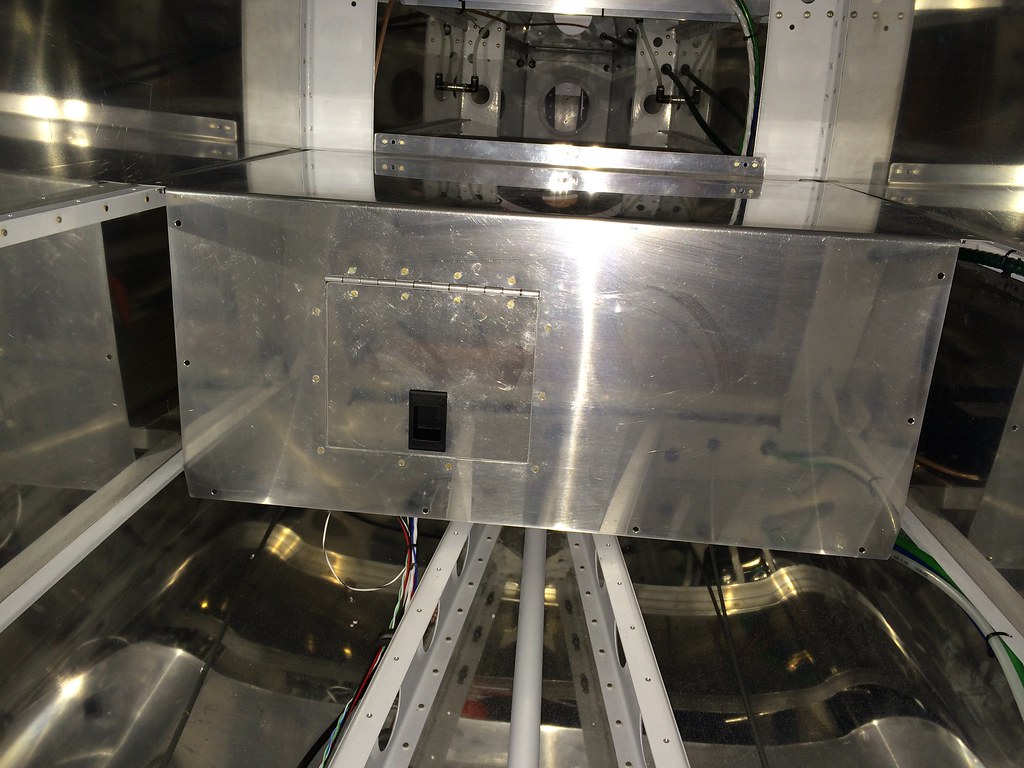

My assumption is that these are non-structural components therefore I plan to remove the bulk head and stepped floor panel. Attach the bottom of the rear bulkhead to the floor panel with a hinge as used in the other locations on the aircraft. Replace the two top screws for the rear bulkhead with quarter turn fittings. Install 6 (estimated) flush latches, three per side (two on the each side of the upper deck and one on each side of the vertical part of the floor panel.

This should make the assembly removable simply by releasing the quarter turn fittings, folding the bulk head forward, and releasing the flush latches on each side of the floor and removing.

Does anyone see a fatal flaw in this?