Can I ask what people are using on the engine side of the firewall?

Reflector/gas barrier over an insulator, with edge sealing and mechanical fasteners.

I read a thread where DanH was going to start selling kits, but can’t find anything.

Ok, an update...

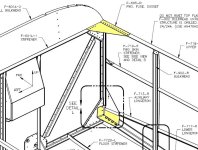

I am selling kits...sort of. The RV-8 kit is a finished product. The 6's, 7's, 9's, and 10's present a problem with the overlap seams for the center recess. As currently configured, the kit will extend cabin fire protected time from

seconds (no, I'm not kidding) to roughly 3 ~ 4 minutes. I am not entirely satisfied with smoke performance.

The primary issue is the use of proseal in that seam. As temperature rises, it tends to liquify, boil out of the joint, and ignite...on the cabin side.

Do not use polysulfide sealant in the firewall seams, period.

I have tested a variety of firewall sealants. The current market is divided between rubber based and silicone based. Any of them is better than polysulfide. None are entirely fireproof. My favorite at this time is Dapco 2100...single component (no waste), with good performance. The budget choice remains 3M FireBarrier 2000+.

The insulation package does eliminate a fundamental failure mode, gapping of the seams, with or without melting of the aluminum rivets, and significantly improves the structural integrity of the firewall support angles.

No sealant is effective given gapping and/or rivet failure.

The current 6-7-9-10 packages are at least an order of magnitude better than none, and light years better than bad insulation on the cabin side. Is it good enough? I've discussed investment, risk, and reward with some smart folks. The universal opinion is that 3 to 4 minutes is a big win given an engine fire, and given normal operating temperatures, the comfort aspect of the current package is fine. Still, I'm trying to improve it, smoke performance in particular, which is why you've not seen any marketing.

Current status? I've put out a few beta installations, and continue to work on improvements. If current performance is good enough, send an email. If not, stay tuned. The big factor for most builders is their progress status. The insulation package needs to go on after all driven rivets are in place, but before populating the firewall with bolted components.

Yes, the folks at Vans are aware of developments, and have been extremely helpful. Enough said.