Hi Bill,

Apologies for the delay in response, I tend to go underground for long periods as work gets intense, then come up for air occasionally.

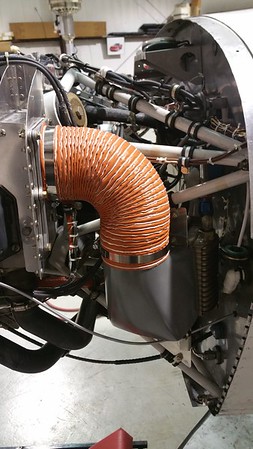

#1: I have the standard Van's 7-row oil cooler, mounted on the aft of the #4 baffle.

#2: It's a frankenmotor - 180hp O-360F1A6 converted to FI with AFP FI and Superior Sump.

3: I'd like to be able to climb out in 90 degree heat at 120mph and keep the oil temperature below 200f. right now, it will go up to 230 if I don't step-climb.

4: This is a typical flight: When everything's warm after some pattern work, if I climb out from SMO (400') at 120mph to 500' with a right turn at around 1000' then on to 4500' I will be at 220f before I get to 3500. Because I'm heading north, I usually level off at 2500, pull back to 23 squared, and let the temp settle down. Then I continue in a slow climb to my target altitude. CHT goes to 400 on Cyl 1 first and usually stays there until I level off, then it settles in at around 370 at cruise, higher or lower depending on OAT.

I've tried to be pretty devout about sealing baffle leaks, but it's entirely possible that I've missed something. But since the CHT's are more or less OK, I'm pretty sure the oil temperature is the result of something else. Is it possible for an oil cooler to get clogged in the first 100 hrs of flight? If so, I would guess that points to a fairly serious issue.

It could also be that my timing is off a bit. I read somewhere (maybe on here) that will lead to increased oil temperature.

cheers

-John

John, a few questions.

1. Do you have the Niagara 20002a cooler?

2. What engine/power do you have.

3. What ambient temp, airspeed (WOT climbing), and oil temp do have for the target cooling condition?

4. What are the temps-speeds do you have not, or said another way - Can you provide an airspeed point, WOT, Ambient and oil temp that is representative.

Niagara has a 9 row cooler that might serve your needs without adding more variables and a lot more cost. You can look up the dimensions and see that the flange is not larger than the 7 row. It will fit on a 7 (depending on how you mounted the 7 row). With attention to above questions, you can determine if it's higher heat transfer capacity will drop the temps to meet your goal.