mill2978

Well Known Member

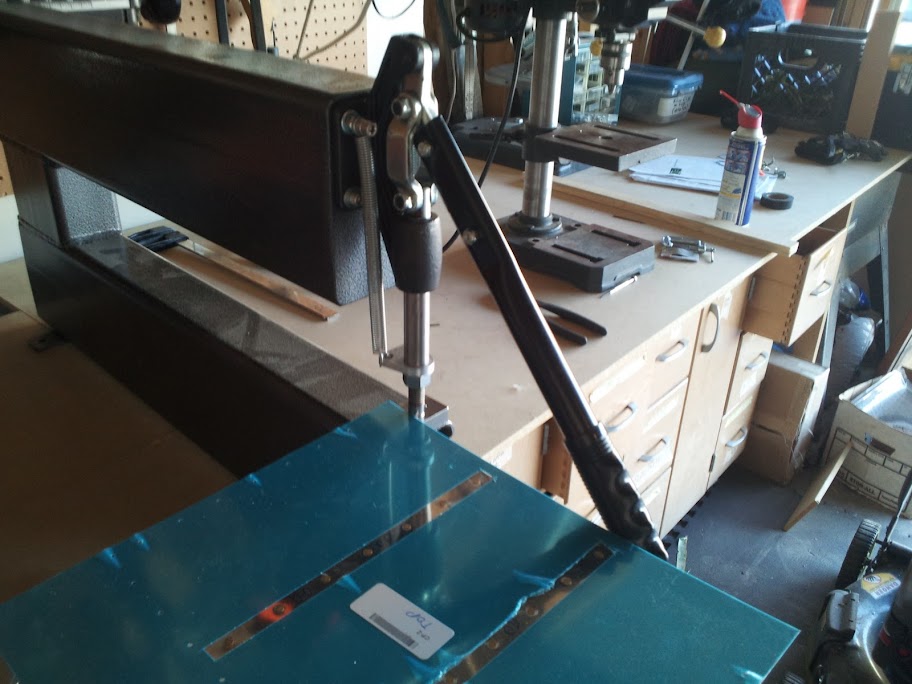

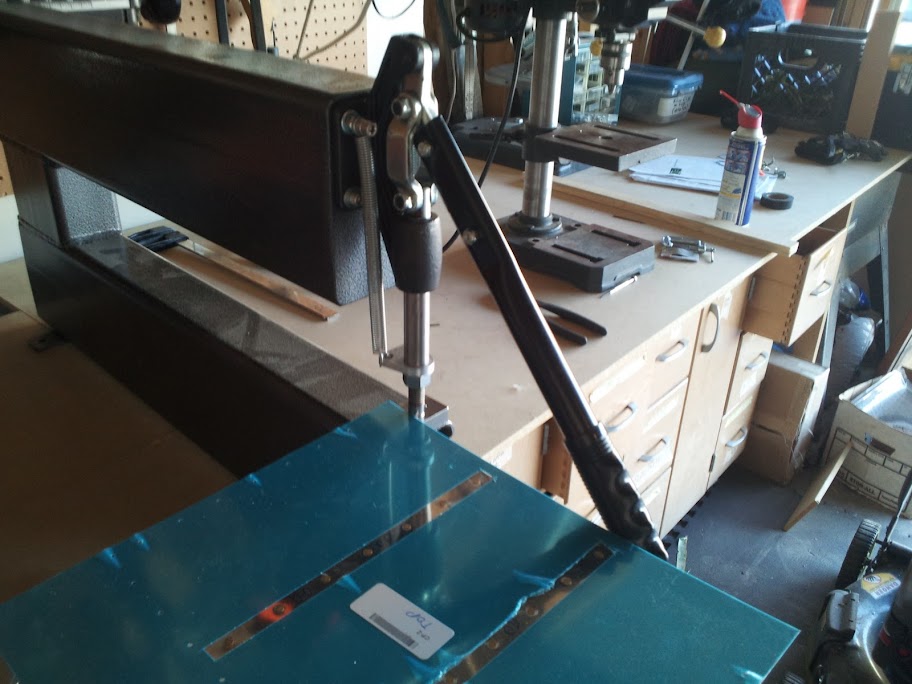

I was using my DRD2 dimpler while working on the practice kit and I got very annoyed with the handle.

It is long enough to drop below the level of the work and get in the way. I took an old push broom handle I had, cut it to 9 inches instead of the 12 that came on the dimpler. I decided to make a new handle instead of cutting down the existing so that if it doesn't work out or fails(it is thinner than the steal handle that came with the dimpler) I still have working dimpler.

I tried it will a few different thicknesses of AL and the increased effort to achieve the dimple is minimal.

It is long enough to drop below the level of the work and get in the way. I took an old push broom handle I had, cut it to 9 inches instead of the 12 that came on the dimpler. I decided to make a new handle instead of cutting down the existing so that if it doesn't work out or fails(it is thinner than the steal handle that came with the dimpler) I still have working dimpler.

I tried it will a few different thicknesses of AL and the increased effort to achieve the dimple is minimal.