Nihon_Ni

Well Known Member

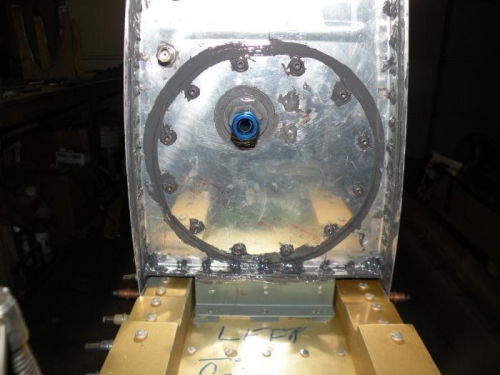

I'm stumped by what to do with the tooling hole in my inboard T-703 rib of the fuel tank, in the area where the T-708 access plate is mounted. The tooling hole at the aft end of the rib extends beyond the T-407 cork gasket and stiffener by a tiny amount, but it's just enough to see daylight through it. The drawing shows this hole as barely under the gasket, as they appear to touch on the outboard edge. My access panel is a fraction forward of where the drawing has it located, and has just uncovered the edge of the tooling hole.

I haven't been able to find anything in the plans to address this hole. Even if it was covered by the cork gasket, there doesn't seem to be enough overlap to seal the hole, since the T-407 stiffener isn't prosealed to the inside of the tank.

Is proseal enough to take care of this if I apply it on both sides? It seems like this a problem in waiting and the hold should be filled with a rivet, but I can't figure out how to get one in there.

What have other builders done to address this tooling hole?

Thanks,

Rob

I haven't been able to find anything in the plans to address this hole. Even if it was covered by the cork gasket, there doesn't seem to be enough overlap to seal the hole, since the T-407 stiffener isn't prosealed to the inside of the tank.

Is proseal enough to take care of this if I apply it on both sides? It seems like this a problem in waiting and the hold should be filled with a rivet, but I can't figure out how to get one in there.

What have other builders done to address this tooling hole?

Thanks,

Rob