Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

trim servo molex connector crimping

- Thread starter Azjulian

- Start date

oh and whats a good source for new male pins so I can get some practice in ?

I just ordered these. I haven't used them yet but, especially with Amazon Prime, it seemed reasonable.

http://www.amazon.com/gp/product/B00LVIHH6A?psc=1&redirect=true&ref_=oh_aui_detailpage_o01_s02

John

RV-8

The micro molex connectors require a specific pin (much smaller than the one in the above post).

I think both genders are available from Van's

I think both genders are available from Van's

rapid_ascent

Well Known Member

You can get the Molex pins from Mouser or Digi-Key. They are a standard part. Mouser seems to have the lowest shipping.

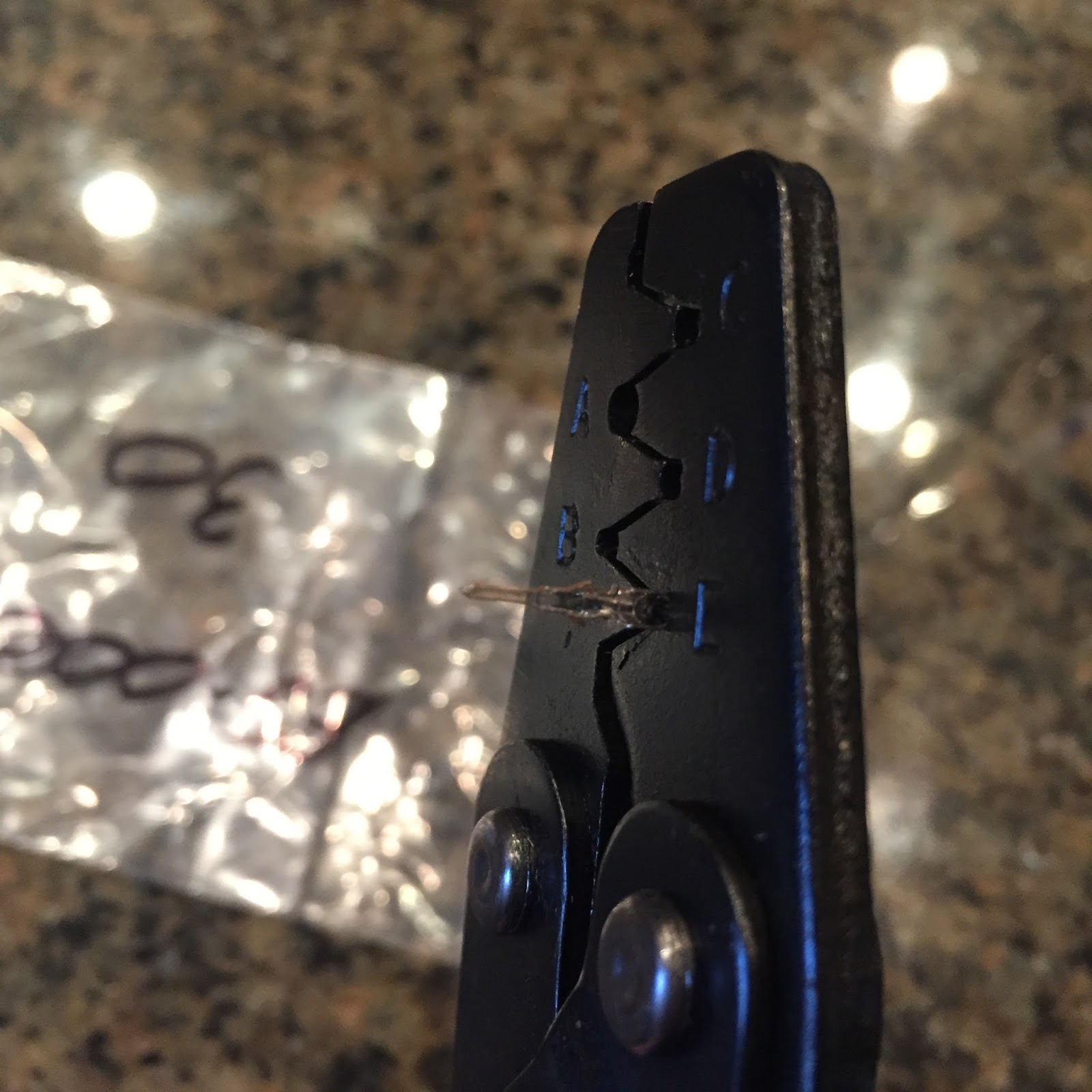

The crimper is a different story. Molex sells a crimper for these contacts but it is $$$$ for the number of crimps that you will be doing. I have a generic crimper that has several smaller crimp positions that seems to work fine if I'm careful. I'm not sure of the brand though. It may even be a Molex but it's not the Microfit crimper.

The crimper is a different story. Molex sells a crimper for these contacts but it is $$$$ for the number of crimps that you will be doing. I have a generic crimper that has several smaller crimp positions that seems to work fine if I'm careful. I'm not sure of the brand though. It may even be a Molex but it's not the Microfit crimper.

Raymo

Well Known Member

Get rid of the molex pins and go with standard D-Sub pins from Stein. No need for a DB9 connector, just ping them and heat shrink for protection. Then one large heat shrink over all the pins.

If you don't need the trim reading on your EFIS, you only need the two white wires.

If you don't need the trim reading on your EFIS, you only need the two white wires.

Last edited:

This is the RV-12 forum.

If a 12 is being built as an E-LSA, there is no option to do what you think is better. In reality, either way requires the proper crimper to install the pins.

The low cost crimper mentioned in section 5 of the manual actually works quite well. It is what we use in my shop.

I would never recommend soldering the pins for a connector at this location on the RV-12 unless the builder was highly skilled at soldering and could avoid any solder wicking into the wire beyond the pin (lots of potential for vibration induced wire movement at this location).

If a 12 is being built as an E-LSA, there is no option to do what you think is better. In reality, either way requires the proper crimper to install the pins.

The low cost crimper mentioned in section 5 of the manual actually works quite well. It is what we use in my shop.

I would never recommend soldering the pins for a connector at this location on the RV-12 unless the builder was highly skilled at soldering and could avoid any solder wicking into the wire beyond the pin (lots of potential for vibration induced wire movement at this location).

Piper J3

Well Known Member

I second the post directly above... A properly crimped connector not only makes solid electrical connection to the wire but adds strain relief with the metal band that crimps over the wire insulation. Soldering will stiffen the stranded wire and cause a point of stress concentration.

I took the advice I found in this forum and bought the SAT-018 crimpers from SteinAir. To create really solid crimps, I first crimped the micro-fit connector onto the insulated wire end.

Then I pushed the wires into the connector, ensured they were seated properly and crimped the wires down. honestly with the SAT-018 crimpers and this really went smoothly and you get a very nice crimp.

Then I pushed the wires into the connector, ensured they were seated properly and crimped the wires down. honestly with the SAT-018 crimpers and this really went smoothly and you get a very nice crimp.

olderthandirt

Well Known Member

Molex connector

I would never disagree with Joe normaly, but I have to say the idea of soldering the connections seems a way better solution than the molex connector and tiny pins..mine did not go together good and sometimes does not make proper contact..I would much prefer solder connection and no question when it comes to trim...sorry Joe

I would never disagree with Joe normaly, but I have to say the idea of soldering the connections seems a way better solution than the molex connector and tiny pins..mine did not go together good and sometimes does not make proper contact..I would much prefer solder connection and no question when it comes to trim...sorry Joe

Spade connectors

My pitch trim servo on serial #0187 Page 11-06 rev 0 has 5 wires and uses

ES421-0108 and ES421-0107 flat spade connectors. These wires mate to the ES WHP30 empenage harness and each hang loose in a loop. Is there a revision and a change to Molex pin connectors at the servo? Or is this concerning the fuselage end of the ESWHP30 harness? I can not find a revision for the pitch trim servo.

The correct Molex crimper can usually be found on eBay surplus for a reasonable price.

Just Google the tool number to be sure it will crimp the terminals you are working on. Molex.com has a wealth of information on wires and crimping plus data sheets on all of their tools.

Jerry

My pitch trim servo on serial #0187 Page 11-06 rev 0 has 5 wires and uses

ES421-0108 and ES421-0107 flat spade connectors. These wires mate to the ES WHP30 empenage harness and each hang loose in a loop. Is there a revision and a change to Molex pin connectors at the servo? Or is this concerning the fuselage end of the ESWHP30 harness? I can not find a revision for the pitch trim servo.

The correct Molex crimper can usually be found on eBay surplus for a reasonable price.

Just Google the tool number to be sure it will crimp the terminals you are working on. Molex.com has a wealth of information on wires and crimping plus data sheets on all of their tools.

Jerry

Bill_H

Well Known Member

All of Section 11 was updated back in 2011.

http://www.vansaircraft.com/public/12_Rev_page2.htm

Molex shown there.

I would check all of the revised plans (the link is to page 2) as you continue the build - there are other updates. You have an early serial number and your plans shipped with it will be early.

http://www.vansaircraft.com/public/12_Rev_page2.htm

Molex shown there.

I would check all of the revised plans (the link is to page 2) as you continue the build - there are other updates. You have an early serial number and your plans shipped with it will be early.

Plan revisions

Bill: Thanks for the link to page 2 I had not noticed the note at bottom of

first page.

"Earlier RV-12 Revisions and Changes have been placed on an additional page.

Click here to go to page 2 of RV-12 Revisions and Changes"

I bought my kit with the empennage assembled, completing wings now.

I have noticed Vans does not use a revision block on the revised drawings with a note to what was changed and why. I can only assume there was an issue with the early design. I plan to change mine now to the new design. I noticed that the servo tray F1287A has a new design in Rev 1 with a cutout for the Molex wire block. But still uses the OLD part number from Rev 0.

I will just order the F1287A part number and see what shows up.

Regards,

Jerry

Bill: Thanks for the link to page 2 I had not noticed the note at bottom of

first page.

"Earlier RV-12 Revisions and Changes have been placed on an additional page.

Click here to go to page 2 of RV-12 Revisions and Changes"

I bought my kit with the empennage assembled, completing wings now.

I have noticed Vans does not use a revision block on the revised drawings with a note to what was changed and why. I can only assume there was an issue with the early design. I plan to change mine now to the new design. I noticed that the servo tray F1287A has a new design in Rev 1 with a cutout for the Molex wire block. But still uses the OLD part number from Rev 0.

I will just order the F1287A part number and see what shows up.

Regards,

Jerry

I can only assume there was an issue with the early design.

The earlier design works just fine, and there are a lot of RV-12's flying in that configuration.

The new design is a bit less sensitive to builder skill, and there is lower risk of damaging the wires if it needs to be disassembled.