Hello and just beginning a thread on an RV-9A project that I am working on in Kalamazoo Mi.

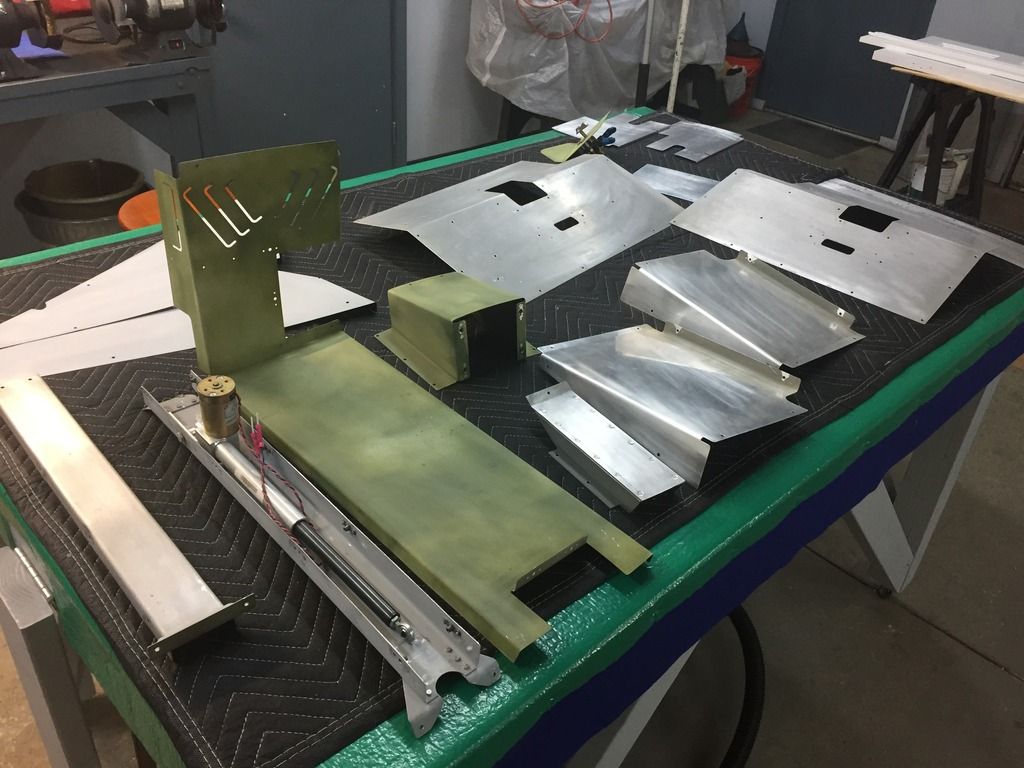

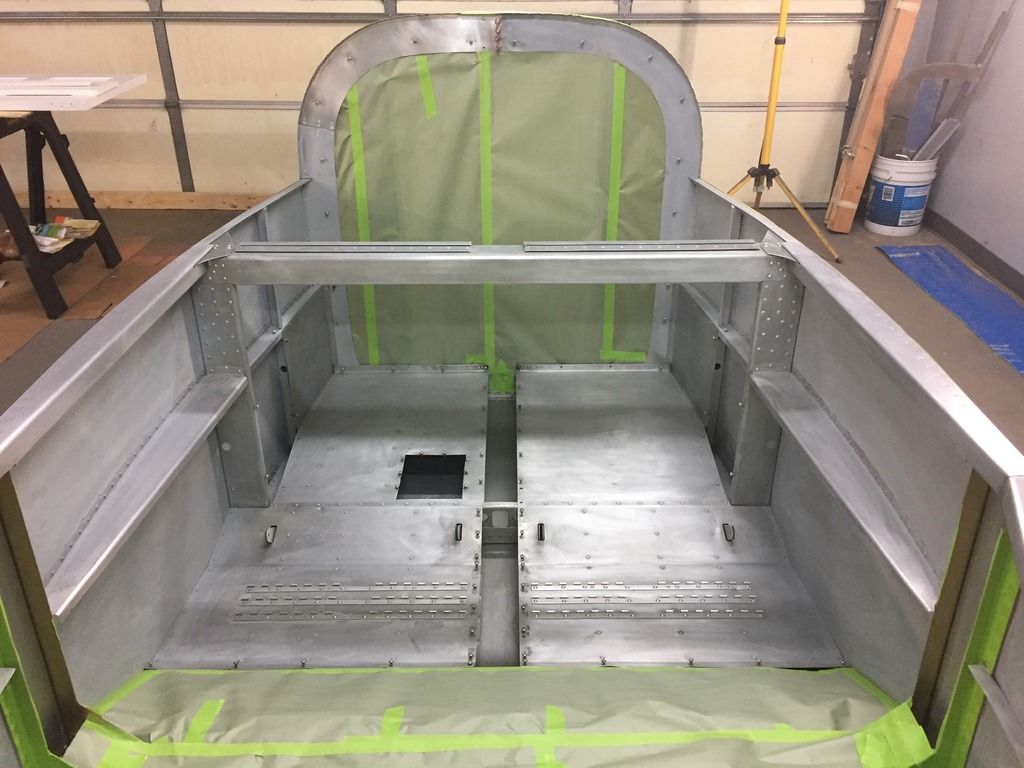

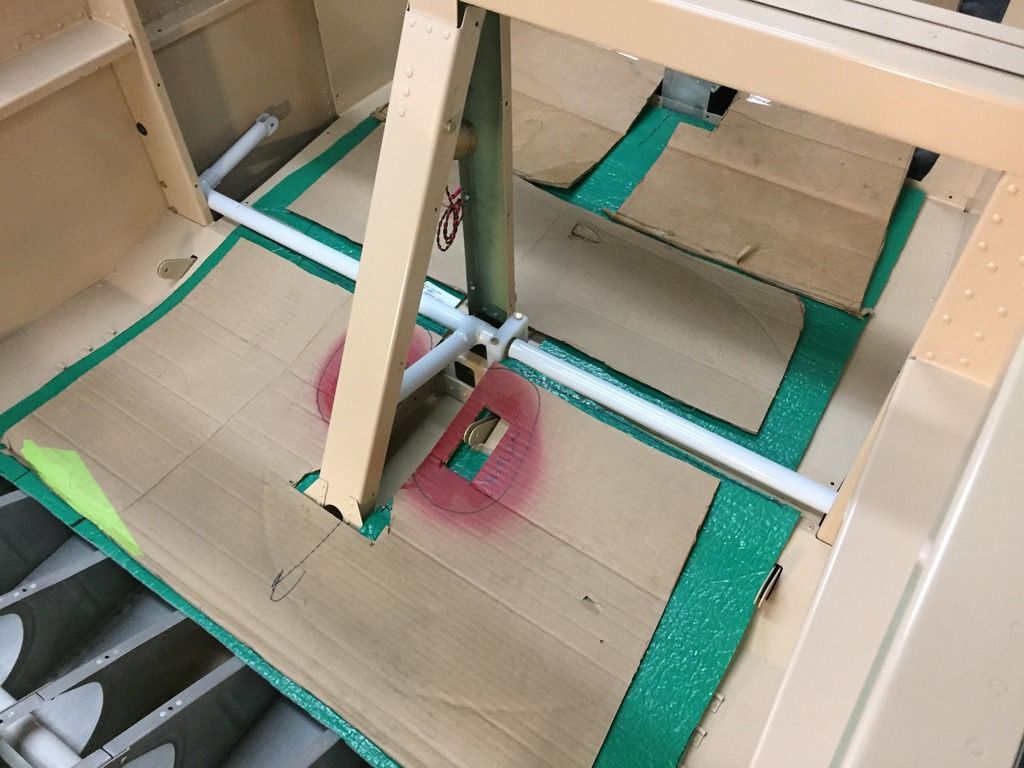

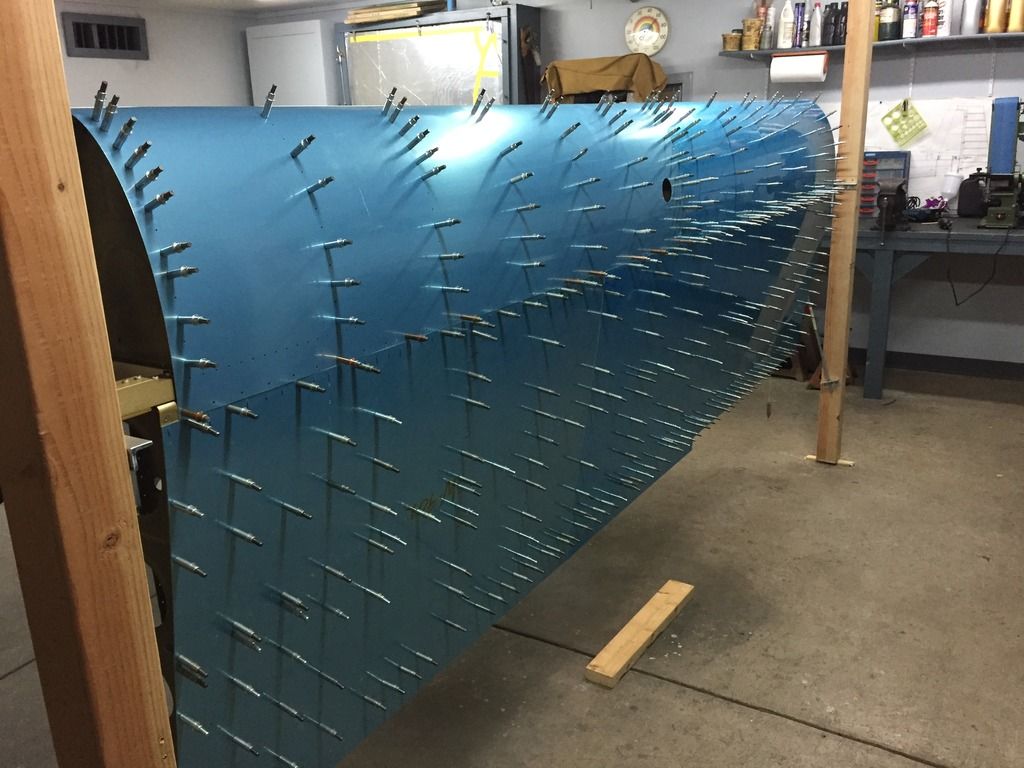

I found this plane not far from me, it was an unfinished kit that another builder began in 2000, the build number is 90072. The picture is the project as I found it, in a Garage about 8 miles from my home.

This is my first Van's build and I am excited with the project! I currently fly a 1946 Cessna 120 that I restored over the last 3-1/2 years.

Looking forward to posting updates as we go,

Andy C.

KazooRV-9A

I found this plane not far from me, it was an unfinished kit that another builder began in 2000, the build number is 90072. The picture is the project as I found it, in a Garage about 8 miles from my home.

This is my first Van's build and I am excited with the project! I currently fly a 1946 Cessna 120 that I restored over the last 3-1/2 years.

Looking forward to posting updates as we go,

Andy C.

KazooRV-9A