SuperCubDriver

Well Known Member

Last week I noticed the oil pressure is around 10 psi lower than before and just in the green. The oil pressure was kind of low from the very beginning when I got the engine new and when I screwed the adjuster screw near the #2 cylinder all the way in.

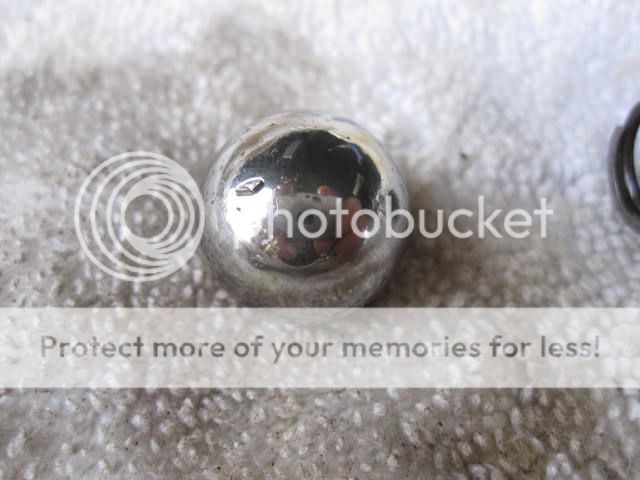

Today I checked the sensor reading against an old fashioned pressure gauge in parallel and they both showed the same pressure. I also blowed compressed air through the oil pressure hose - into the engine. The adjuster screw is still responsive, oil pressure is lower when backing off the adjuster screw.

Some time ago I read there are different springs out there for the oil adjuster screw, can someone confirm this? Any more infos are very welcome, spring rate, part numbers and where to get them and how to install them. I?m also interested in the part number for the seal which goes under the fixture, it is about 1.5" diameter, looks like copper asbestos.

Any hint is welcome.

The engine is an IO-375 with CS-Prop, 450 hours since new. Just changed the oil and filter and filled up with Aeroshell 15W-50 as usual. Engine runs very well and burns almost no oil.

Sorry for the long post.

Today I checked the sensor reading against an old fashioned pressure gauge in parallel and they both showed the same pressure. I also blowed compressed air through the oil pressure hose - into the engine. The adjuster screw is still responsive, oil pressure is lower when backing off the adjuster screw.

Some time ago I read there are different springs out there for the oil adjuster screw, can someone confirm this? Any more infos are very welcome, spring rate, part numbers and where to get them and how to install them. I?m also interested in the part number for the seal which goes under the fixture, it is about 1.5" diameter, looks like copper asbestos.

Any hint is welcome.

The engine is an IO-375 with CS-Prop, 450 hours since new. Just changed the oil and filter and filled up with Aeroshell 15W-50 as usual. Engine runs very well and burns almost no oil.

Sorry for the long post.