As of right now, 91% of the responders of the oil puddle poll would pull the cowl and investigate. So the cowl is pulled and you find oil inside the cowl and what appears to be a crack in the paint on the through stud boss in front of the #2 cylinder. The stud is one of the 4 larger studs that hold the #1 cylinder to the engine and is right below the oil galley.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil on engine and inside cowl

- Thread starter RV6_flyer

- Start date

flyboykelly

Well Known Member

Still normal for me

Actually had this happen with a rental plane of my employer. Renter left it 90 miles away because of oil in the cowl. The crankshaft seal was then replaced. I went to pick it up and found a crack in front of the #2 cylinder that leaked oil while running. I left it there and had the engine removed.

Chris

Chris

David-aviator

Well Known Member

Me thinks Gary is bored in retirement and has created an Oil Leak 101 course.

Time to think about building another airplane Gary, like the 8. That will light your fire more than this effort.

You pushed the envelope just a little to far with the 6 engine, nothing lasts forever not even a Lycomiing engine. Metal wears out.

Time to think about building another airplane Gary, like the 8. That will light your fire more than this effort.

You pushed the envelope just a little to far with the 6 engine, nothing lasts forever not even a Lycomiing engine. Metal wears out.

RV8Squaz

Well Known Member

As of right now, 91% of the responders of the oil puddle poll would pull the cowl and investigate. So the cowl is pulled and you find oil inside the cowl and what appears to be a crack in the paint on the through stud boss in front of the #2 cylinder. The stud is one of the 4 larger studs that hold the #1 cylinder to the engine and is right below the oil galley.

If indeed you have a cracked case, you are grounded, period, end of story. Engine removal, repair, and replacement is the only answer.

I once found a "small" crack on my number 3 cylinder during a routine compression check. The cylinder wouldn't hold any air; my compression was 10/80! The air leak was sufficient to blow what's left of my hair! How this engine ran without a noticeable power loss, I don't know! There was a small crack in the "paint" next to the top spark plug hole.

In any case, jabarr and I removed the cylinder and it was determined that this crack went halfway around the circumference of the cylinder. No one knows how long it would have continued to run, 10 hours, 1 hour, 10 minutes?

Clean the engine, run it, and look. Blowing talc on a clean engine and then running it to highlight a leak is a neat trick I recently learned.

Jerry Esquenazi

RV-8 N84JE

Last edited:

Here is the story.

Cowl was pulled to check after landing. Mess cleaned up and a run up accomplished. (Sunday)

This is what it looked like after the ground run-up.

The oil at the bottom of the stud / boss was not there before the run-up and there was more oil on the baffle. The suspected crack can be seen in the paint running up from the stud on the boss.

The airplane had the cowl put back on and was tied down for the night. I got ground transportation home.

Since I am an A&P and did not like what I saw, I asked another A&P (Retired US Airway), multi-RV builder, and all around great guy to look over what I saw the next day and give me his opinion.

The next day, we pulled the cowl and use a wire wheel on a drill to clean paint from the area. (Monday) This is what we found:

The gold color stuff is oil. Engine was cold and ran less than one minute.

I did not ask if the airplane should or should not be flown. I would not fly it in that condition.

This is what happened on Tuesday:

Thursday the airplane looked like this:

Saturday, this photo was taken in Mississippi:

It is now Sunday and I am home with the truck and replacement engine.

Some work still needs to be done. I bet someone finds something else wrong in at least one of the photos.

Cowl was pulled to check after landing. Mess cleaned up and a run up accomplished. (Sunday)

This is what it looked like after the ground run-up.

The oil at the bottom of the stud / boss was not there before the run-up and there was more oil on the baffle. The suspected crack can be seen in the paint running up from the stud on the boss.

The airplane had the cowl put back on and was tied down for the night. I got ground transportation home.

Since I am an A&P and did not like what I saw, I asked another A&P (Retired US Airway), multi-RV builder, and all around great guy to look over what I saw the next day and give me his opinion.

The next day, we pulled the cowl and use a wire wheel on a drill to clean paint from the area. (Monday) This is what we found:

The gold color stuff is oil. Engine was cold and ran less than one minute.

I did not ask if the airplane should or should not be flown. I would not fly it in that condition.

This is what happened on Tuesday:

Thursday the airplane looked like this:

Saturday, this photo was taken in Mississippi:

It is now Sunday and I am home with the truck and replacement engine.

Some work still needs to be done. I bet someone finds something else wrong in at least one of the photos.

skylor

Well Known Member

I bet someone finds something else wrong in at least one of the photos.

Purple?!?!

JK!

Skylor

Nothing at all wrong with Purple! Tsam has lots of it.....good DNA Condor!

AlexPeterson

Well Known Member

I bet someone finds something else wrong in at least one of the photos.

#2 pipe dark brown?

LettersFromFlyoverCountry

Well Known Member

You're a faster worker. I think it would've taken me a week just to get one of the wings off....

#2 pipe dark brown?

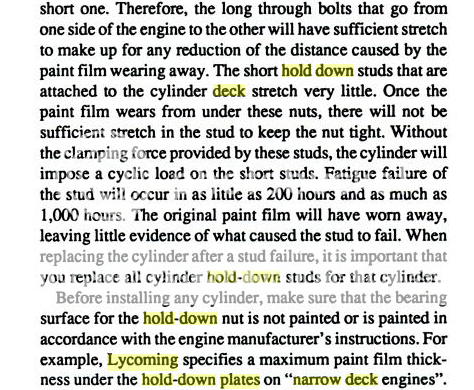

Cylinder hold down plates are painted. They should not be. The short cylinder studs will break in 100-hours or so because of the paint.

ijustwannafly

Well Known Member

how about some JB weld to get her home!

just kidding. My vote. take the night off. Get a car, drive 17 miles home. Have a beer and figure out a good plan of action the next day which obviously you are way ahead of that

just kidding. My vote. take the night off. Get a car, drive 17 miles home. Have a beer and figure out a good plan of action the next day which obviously you are way ahead of that

Gary what exactly were you describing about above about something being painted and causing a failure?

Gary what exactly were you describing about above about something being painted and causing a failure?

Kyle Boatright

Well Known Member

Gary what exactly were you describing about above about something being painted and causing a failure?

You cannot allow paint between the case halves, between the cylinder bases and the case, or under the nuts which hold the crankcase halves together or which hold the cylinders to the crankcase.

Under the heat and vibration, the paint will be ground to dust, fall away, and that will reduce the clamping force which holds the entire mess together. Once the clamping force is removed, things will begin to move around a bit, ultimately resulting in broken studs and more expensive problems.

ijustwannafly

Well Known Member

You cannot allow paint between the case halves, between the cylinder bases and the case, or under the nuts which hold the crankcase halves together or which hold the cylinders to the crankcase.

Under the heat and vibration, the paint will be ground to dust, fall away, and that will reduce the clamping force which holds the entire mess together. Once the clamping force is removed, things will begin to move around a bit, ultimately resulting in broken studs and more expensive problems.

ah ok, noted thanks

how about some JB weld to get her home!

just kidding. My vote. take the night off. Get a car, drive 17 miles home. Have a beer and figure out a good plan of action the next day which obviously you are way ahead of that

Gary what exactly were you describing about above about something being painted and causing a failure?

You cannot allow paint between the case halves, between the cylinder bases and the case, or under the nuts which hold the crankcase halves together or which hold the cylinders to the crankcase.

Under the heat and vibration, the paint will be ground to dust, fall away, and that will reduce the clamping force which holds the entire mess together. Once the clamping force is removed, things will begin to move around a bit, ultimately resulting in broken studs and more expensive problems.

Kyle answered correctly. Here is a little snippet from Sky Ranch Manual. Lycoming paperwork does not come out and say it as clearly.

Marc DeGirolamo

Well Known Member

Straps on flange

Gary,

I don't think I would use the crankshaft flange as a place for the tie-down straps..... Just me and and an extremely expensive hunk of metal??

Gary,

I don't think I would use the crankshaft flange as a place for the tie-down straps..... Just me and and an extremely expensive hunk of metal??

KatieB

Well Known Member

You're a faster worker. I think it would've taken me a week just to get one of the wings off....

+1 for that!

Great thread, Gary.

AX-O

Well Known Member

How many hours on the failed engine? Just wondering where it fell between the 200 and 1000 hours noted in the article snippet.

the paint is on the new engine not the old. unless I read the thread wrong. Pics support that too.

AZtailwind

Well Known Member

Some work still needs to be done. I bet someone finds something else wrong in at least one of the photos.

Still 160 HP

How many hours on the failed engine? Just wondering where it fell between the 200 and 1000 hours noted in the article snippet.

The snippet is about stud failure due to paint on hold down plates. Has nothing to do with the oil leak.

The old engine was manufactured in 1961. It has 6,100+ hours total time and over 2,600 since the case was last split.