Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inlet Manifold Gasket Failure

- Thread starter RV10inOz

- Start date

flyingriki

Well Known Member

Bill, you must not have read my note!

N941WR

Legacy Member

Bill, you must not have read my note!

No, I did not. I was running late. Ripped open the envelope, saw what it was, tossed them on the counter, and ran out the door.

flyingriki

Well Known Member

Thank you all for being true to your requests. Hope these work for you all. Feel like I paid back a little for the help I've gotten here!

Bill Dicus

Well Known Member

Thanks. Will look at mailbox! Bill

flyingriki

Well Known Member

Thanks. Will look at mailbox! Bill

Don't recognize your name. Don't look too hard....

Vansrv7arob

Well Known Member

7 months on is there any update on this tjread?

flyingriki

Well Known Member

This fellow considered ordering another 100 to distribute:

I'd be OK with running the next order if you pass information.

Thanks

John Collier

__________________

John Collier

RV8

N774BC

Niceville, FL

But he may have just ordered them from the guy that was doing testing to sell for profit.

I'd be OK with running the next order if you pass information.

Thanks

John Collier

__________________

John Collier

RV8

N774BC

Niceville, FL

But he may have just ordered them from the guy that was doing testing to sell for profit.

Toobuilder

Well Known Member

I also have about 100 hours on mine and they are holding up fine.

However, they are very fiddly to install properly. They are so soft that it's difficult to keep the tube centered in the counterbore of the tube retainer, and a little bit too much torque and they extrude into the port. Before you discard that last statement I'd like to qualify it by saying I'm an A&P and have been maintaining aircraft engines my entire adult life - they are extremely sensitive to torque and position. The required torque is far lighter than the norm for this size fastener.

I'd like to see them made of a higher durometer material or perhaps a fabric impregnated silicone (like cowl baffle seal) to keep it from extruding into the port.

However, they are very fiddly to install properly. They are so soft that it's difficult to keep the tube centered in the counterbore of the tube retainer, and a little bit too much torque and they extrude into the port. Before you discard that last statement I'd like to qualify it by saying I'm an A&P and have been maintaining aircraft engines my entire adult life - they are extremely sensitive to torque and position. The required torque is far lighter than the norm for this size fastener.

I'd like to see them made of a higher durometer material or perhaps a fabric impregnated silicone (like cowl baffle seal) to keep it from extruding into the port.

I also have about 100 hours on mine and they are holding up fine.

However, they are very fiddly to install properly. They are so soft that it's difficult to keep the tube centered in the counterbore of the tube retainer, and a little bit too much torque and they extrude into the port. Before you discard that last statement I'd like to qualify it by saying I'm an A&P and have been maintaining aircraft engines my entire adult life - they are extremely sensitive to torque and position. The required torque is far lighter than the norm for this size fastener.

I'd like to see them made of a higher durometer material or perhaps a fabric impregnated silicone (like cowl baffle seal) to keep it from extruding into the port.

This was the #1 concern I had when I saw so many people jumping on the experimenting with their engine band wagon.

flyingriki

Well Known Member

.... they are extremely sensitive to torque and position. The required torque is far lighter than the norm for this size fastener.

I used locking nuts so the torque wasn't necessary.

Toobuilder

Well Known Member

I just happened to pull a few intake tubes off tonight for other maintenance and these are still doing fine. However, I decided to put my money where my mouth was and made up a new gasket out of some red (fabric reinforced) baffle seal. I installed it as a trial fit and found that just as I suspected, you can smoke the bolts down as tight as reason allows and there is no distortion or extrusion. Additionally, the flange remains solidly in the retainer counterbore with little possibility of jumping out. As a side note, I did find one of mine off center today. Considering the care and attention I paid to this exact issue on istallation and the extremely light clamping loads, I think it's a reasonable assumption that the tube moved in service. I'm not certain mind you- just mentioning it so that you can inspect yours from time to time. Its a simple visual inspection - just make sure the tube is centered in the retainer.

Anyway, I will fly this one gasket I made and see how it holds up. If it works well, then maybe someone with a waterjet can make a run.

Anyway, I will fly this one gasket I made and see how it holds up. If it works well, then maybe someone with a waterjet can make a run.

I used locking nuts so the torque wasn't necessary.

Studs on the intake tubes??

I need to replace the intake gaskets on two of my tubes...

I found this part on Aircraft Spruce but it doesn't say what engine it's for...

"SUPERIOR SA629925 GASKET, INTAKE MANIFOLD"

I have an o-360, is this the gasket I need?

tks

Yes.

Vic

RVG8tor

Well Known Member

Green gasket

I have 500 hours on my engine and no issues with intake tubes until last week. I have one small drip down an intake tube, no issues in the operation of the engine.

My gaskets are green, would this be the Superior gaskets. I want to get some to have on hand, annual coming up soon. I assume it is a good idea to change the rubber hose used to attach the intake tubes to the sump. Is there any best products for this or just standard Lycomoing part?

Thanks for any help

Cheers

I have 500 hours on my engine and no issues with intake tubes until last week. I have one small drip down an intake tube, no issues in the operation of the engine.

My gaskets are green, would this be the Superior gaskets. I want to get some to have on hand, annual coming up soon. I assume it is a good idea to change the rubber hose used to attach the intake tubes to the sump. Is there any best products for this or just standard Lycomoing part?

Thanks for any help

Cheers

edneff

Well Known Member

I have 500 hours on my engine.... I assume it is a good idea to change the rubber hose used to attach the intake tubes to the sump. Is there any best products for this or just standard Lycomoing part?

My A&P looked at the rubber hoses and he said "no cracks, they are fine... use them"

But I forgot to ask him what the nuts should be torqued to when reinstalling the tubes, anyone have that spec?

Tks

snopercod

Well Known Member

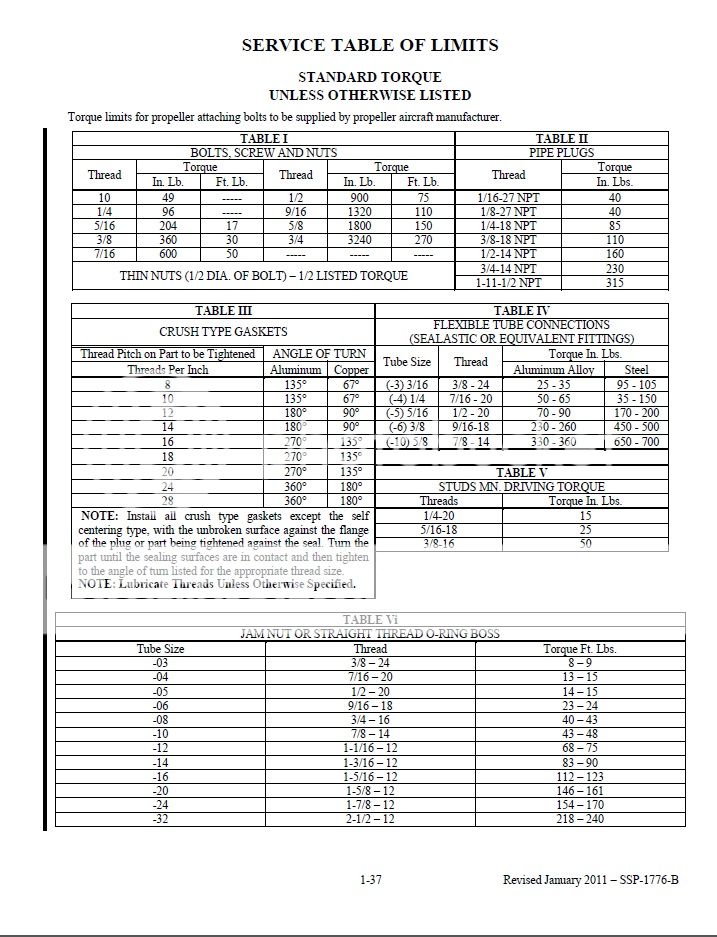

Apparently, nobody has that spec. It's not in the Lycoming table of limits (my old version, anyway). I used 96 in.lb. on those nuts....anyone have that spec?

scsmith

Well Known Member

how are everyone's gaskets doing?

Its interesting that this topic appeared and there was a great deal of interest about 2 years ago. And since then, all quiet. What became of the Mcminn fellow and his beta test of gaskets? Did he eventually do a production run?

Everyone that installed Rik's gaskets still happy with them despite the apparent tendency to creep and extrude?

Are the Superior gaskets working ok for most people?

I have about 420 hrs on an angle-valve IO-360. No symptoms so I have not looked really close, although I do give a cursory look every oil change. I will look super close this time, but would just like to know how everyone is doing with this. It flared up with such intense interest and then 'poof'..

Its interesting that this topic appeared and there was a great deal of interest about 2 years ago. And since then, all quiet. What became of the Mcminn fellow and his beta test of gaskets? Did he eventually do a production run?

Everyone that installed Rik's gaskets still happy with them despite the apparent tendency to creep and extrude?

Are the Superior gaskets working ok for most people?

I have about 420 hrs on an angle-valve IO-360. No symptoms so I have not looked really close, although I do give a cursory look every oil change. I will look super close this time, but would just like to know how everyone is doing with this. It flared up with such intense interest and then 'poof'..

Toobuilder

Well Known Member

...Everyone that installed Rik's gaskets still happy with them despite the apparent tendency to creep and extrude?...

Id be happy if they didnt creep and extrude. They work for the most part, but are not "the" solution, IMHO.

If the Lycoming retainer could be machined with an O ring groove at the head interface and also at the ID of the intake pipe (that is, between the retainer and intake pipe) that would likely be ideal. These O rings should be common, hardware store items available everywhere for pennies, too (as long as I'm dreaming).

scsmith

Well Known Member

Id be happy if they didnt creep and extrude. They work for the most part, but are not "the" solution, IMHO.

If the Lycoming retainer could be machined with an O ring groove at the head interface and also at the ID of the intake pipe (that is, between the retainer and intake pipe) that would likely be ideal. These O rings should be common, hardware store items available everywhere for pennies, too (as long as I'm dreaming).

Hardware store o-rings won't take 400F cylinder temps. Silicone o-rings will.

I can't visualize how you would get an o-ring gland between the intake pipe and the retainer, but its been a while since I've looked at them. It would have to go on the back side of the flared flange, right?

I think an appropriate gasket material would solve this permanently. Cloth-impregnated silicone would be ideal.

Ever look at an intake manifold gasket on a car? metal crush rings, often metal mesh laminated into the treated paper. (of course, this is mostly because the same gasket also seals the exhaust ports...at least on the cars I used to work on as a kid)

Toobuilder

Well Known Member

Hardware store o-rings won't take 400F cylinder temps. Silicone o-rings will.

I can't visualize how you would get an o-ring gland between the intake pipe and the retainer, but its been a while since I've looked at them. It would have to go on the back side of the flared flange, right?...

If you are seeing 400 at the intake port, the engine is on fire. IIRC, Ross did some research before releasing his "direct port" fuel injection adapters for the SDS system and the highest that area of the head sees is a bit over 200. But considering the proximity to the exhaust port, there might be some areas of high temps. Even silicone O-rings are cheap, however.

But yes, the one O ring would have to nest right above (behind?) the shoulder of the intake tube to seal the tube to the retainer. The other one would have to be outside the flange of the steel tube and would seal the retainer to the head. I dont have one in my hand, but there is not a bunch of real estate there so it may not even be possible.

On the other hand, I have a lathe....

Great! A new project to distract me from getting the Rocket back in the air.

Last edited:

Planecrazy232

Well Known Member

What about this method??

http://www.vansairforce.com/community/showthread.php?t=120750&highlight=Intake+gaskets

http://www.vansairforce.com/community/showthread.php?t=120750&highlight=Intake+gaskets

az_gila

Well Known Member

I say again:

Does anyone have the torque spec for the nuts attaching the inlet tubes???

Thanks

If they are not listed as special torque in the overhaul manual they default to the Lycoming "standard" torques.

They are not listed under special torques...

edneff

Well Known Member

If they are not listed as special torque in the overhaul manual they default to the Lycoming "standard" torques.

They are not listed under special torques...

Thanks! That will come in handy!