Like everything these days, it seems that there is no single best answer and a bit of perspective can be helpful.

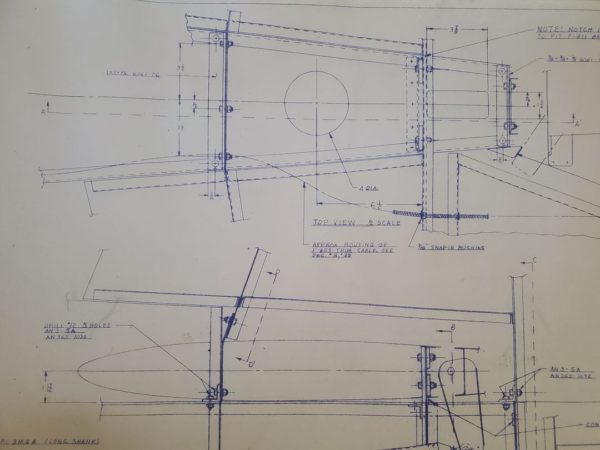

In my case, this change is not as simple as is often implied here because I have a very early -4, SN 107. The HS attach is a bit different than the current plans. Basically, the aluminum angle is forward of the F-10 bulkhead (which is the F-410 and F-410A bulkheads in the current plans) and that bulkhead is sandwiched between the HS spar and angle. (there is no F-410A bulkhead like in the current plans)

So, the first issue is getting at the bolts (that pass thru the aluminum angle/longeron) which can only be accessed from inside the tail. That will require removing the elevator push rod. I'm fairly confident (optimistic) that I can get in there. But... I seriously doubt I'll ever get out. My rotting corpse back there will seriously throw off the CG and decrease the value so, I probably need to rent a small/handy child.

Secondly, the aluminum angle and HS spar sandwhich the F-10 bulkhead. So, raising the HS is going to cause the bolt holes in the bulkhead to be elongated. Or, one must drill new holes (in different places) thru the entire sandwhich (angle, HS spar, and bulkhead).

I've seen an installation that moved the aluminum angle aft of F-10 which slightly improves access but one still has the sandwhich bolts to deal with. And, one is adding a couple of holes thru the longeron. Are all the additional holes ok? I don't know - thus I'm still flying with an out of trim elevator. :-(

I know... an email to the mothership is in order...