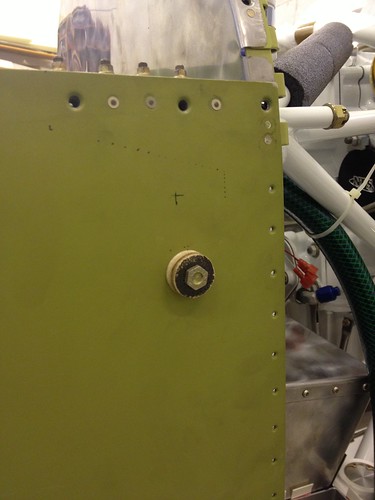

I'm going to be cutting a couple of round holes in my RV 4 to install a pair of ULTIMATE VENTILATOR's

So, I don't see anything much in the way of using circle cutters that are attached to the end of a drill with a pilot bit then followed by a hole cutter such as what is used on wood.

So is there anything designed for aluminum built similar to this?

Or is my best bet is to order the Circle Cutter that is on Air Craft Spruce that looks like Scribe powered by a drill?

http://www.aircraftspruce.ca/catalog/topages/holecutter.php?clickkey=29428

Any recommendation on what to use for tools for this as well as what to do or not do? I will practice on some scrap aluminum 1st to make sure I get it right the first time.

Thanks

Tim

So, I don't see anything much in the way of using circle cutters that are attached to the end of a drill with a pilot bit then followed by a hole cutter such as what is used on wood.

So is there anything designed for aluminum built similar to this?

Or is my best bet is to order the Circle Cutter that is on Air Craft Spruce that looks like Scribe powered by a drill?

http://www.aircraftspruce.ca/catalog/topages/holecutter.php?clickkey=29428

Any recommendation on what to use for tools for this as well as what to do or not do? I will practice on some scrap aluminum 1st to make sure I get it right the first time.

Thanks

Tim