SuperCubDriver

Well Known Member

Here is a report with an incident during departure which caught my attention:

Last Friday I was taking off from LOWZ airfield in Austria on Rwy 08 with my RV-7. When I reached a height of 500 ft the engine suddenly was shaking with a significant power loss. I immediately pushed the nose over and turned right knowing I hava to land ASAP. Two options came to mind - a short pattern or land on opposite rwy, chosed the second option as I was in a good position for it. I glanced at the instruments and saw cyl 2 is gone (not physically). Engine was still responsive but with reduced power and out of balance. I radioed I was having trouble and will come in on rwy 26. The approach was not pushed and good on speed and altitude being aware of about 2 kts tailwind on the 2500 ft rwy. I came in slightly high and the plane just didn´t wan´t to descent and become slower, somehow the engine was still producing power and I pulled hard on the throttle - no change.

Now I realized I will not make it and end up in the bushes at the end of the rwy. I made a bad decision but was lucky with it and did go around being aware I could crashland in the golf course ahead. I retracted the flaps to 10 and did a shallow climb with a slight left turn for a teardrop pattern. Then I came in high assuring to make the rwy. Again the airplane didn´t want to descent as usual, there is still the power just like on the first approach. I pulled the mixture and shut the engine down and she descendet normal towards the rwy for a reliefing landing. During rollout I pushed the mixture in again to keep the engine running for a taxi-out. I realized that the RPM was around 1200 while it should be around 650 - so it was really running with power and this explains the unsuccessful approach.

I can tell you that during these two seconds floating over the rwy realizing not to make it and having two bad options left is no fun at all. It is completely different analysing this later on the ground with all the information available.

A question for the engine gurus here:

What could have caused the power increase at idle setting?

My guess is that the sticking exhaust valve in open position acted like an"aggressive cam" with some significant valve overlap so the idle MAP was increased (less vacuum in the intake manifold).

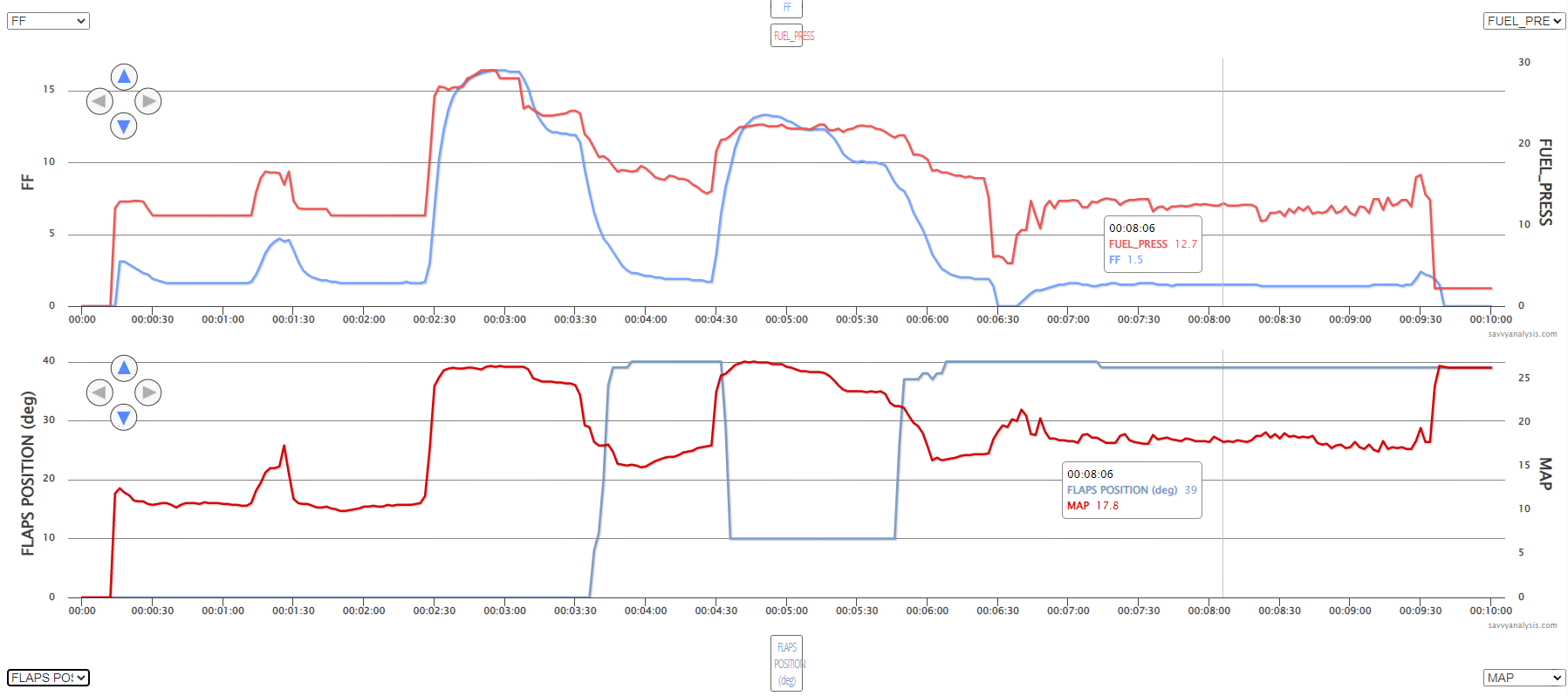

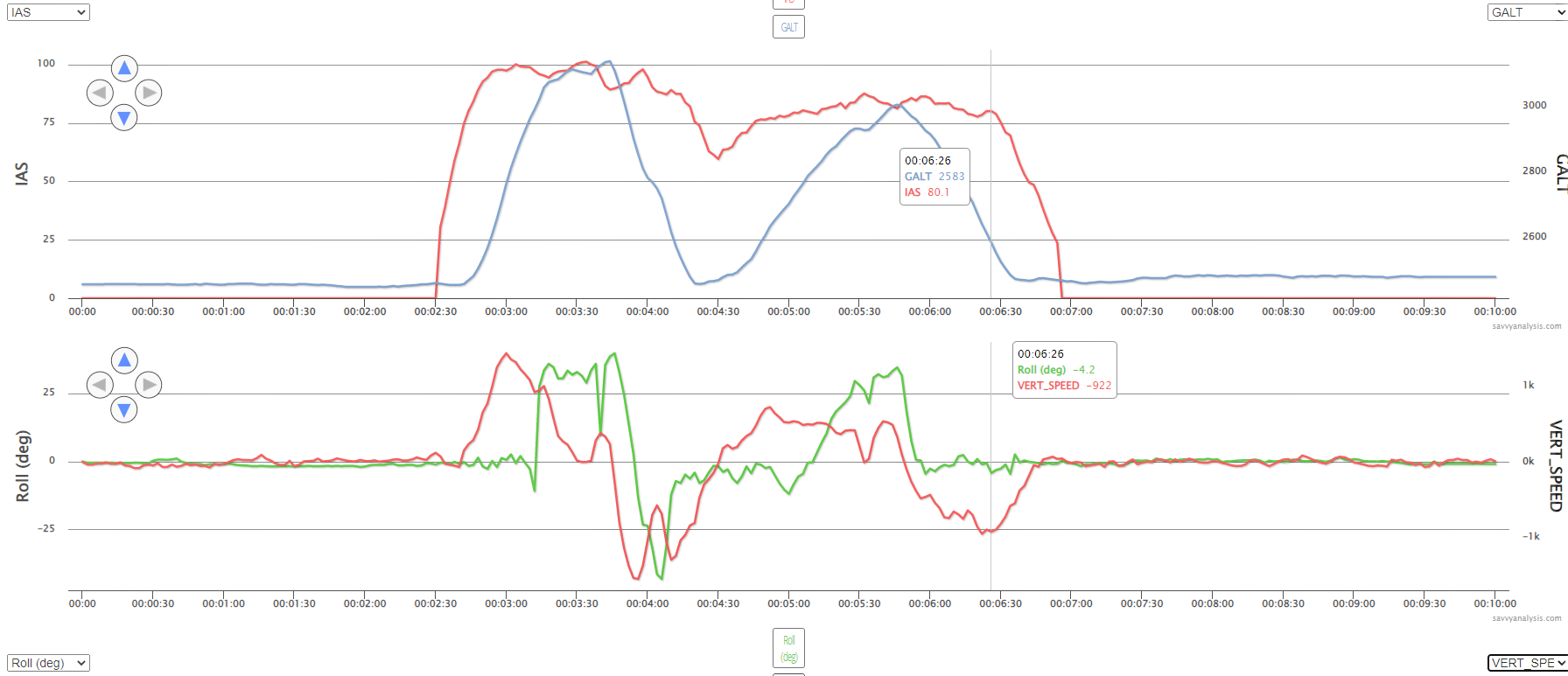

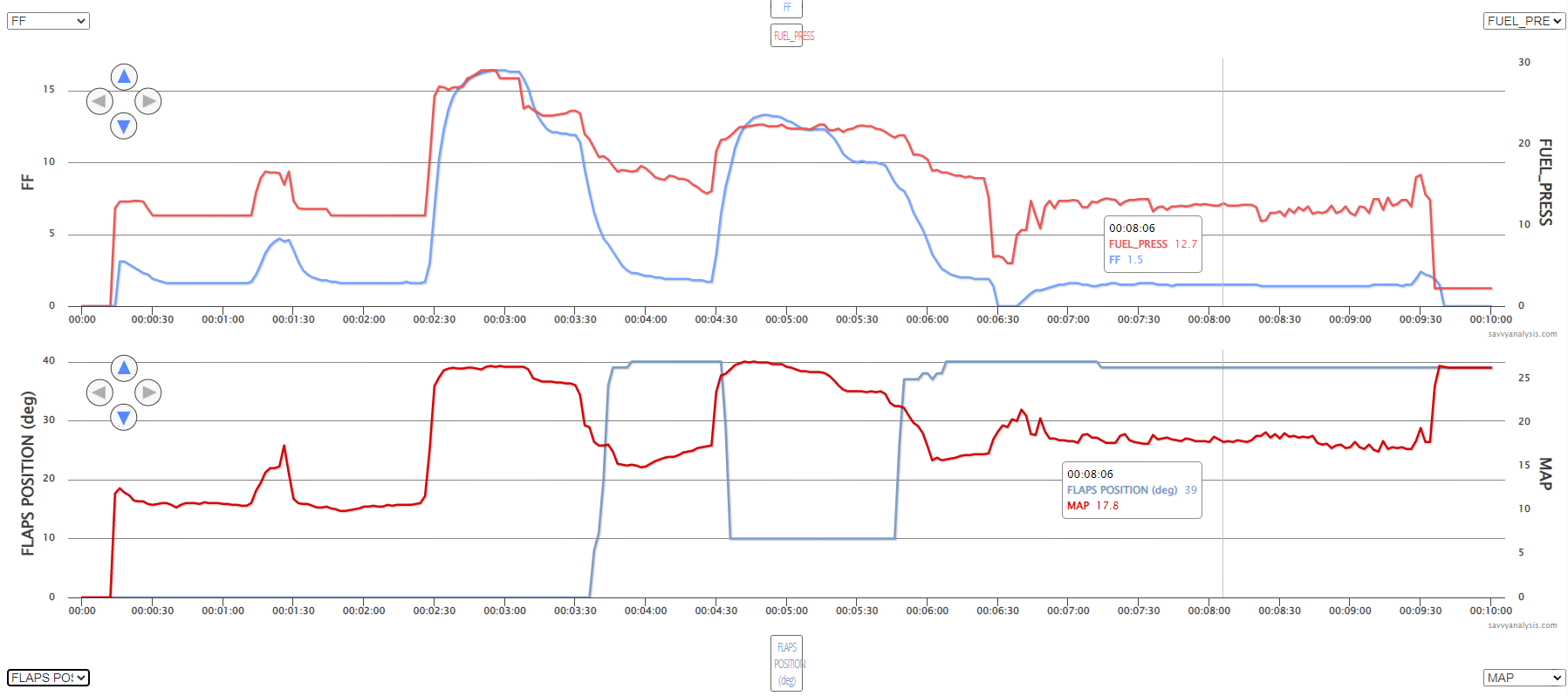

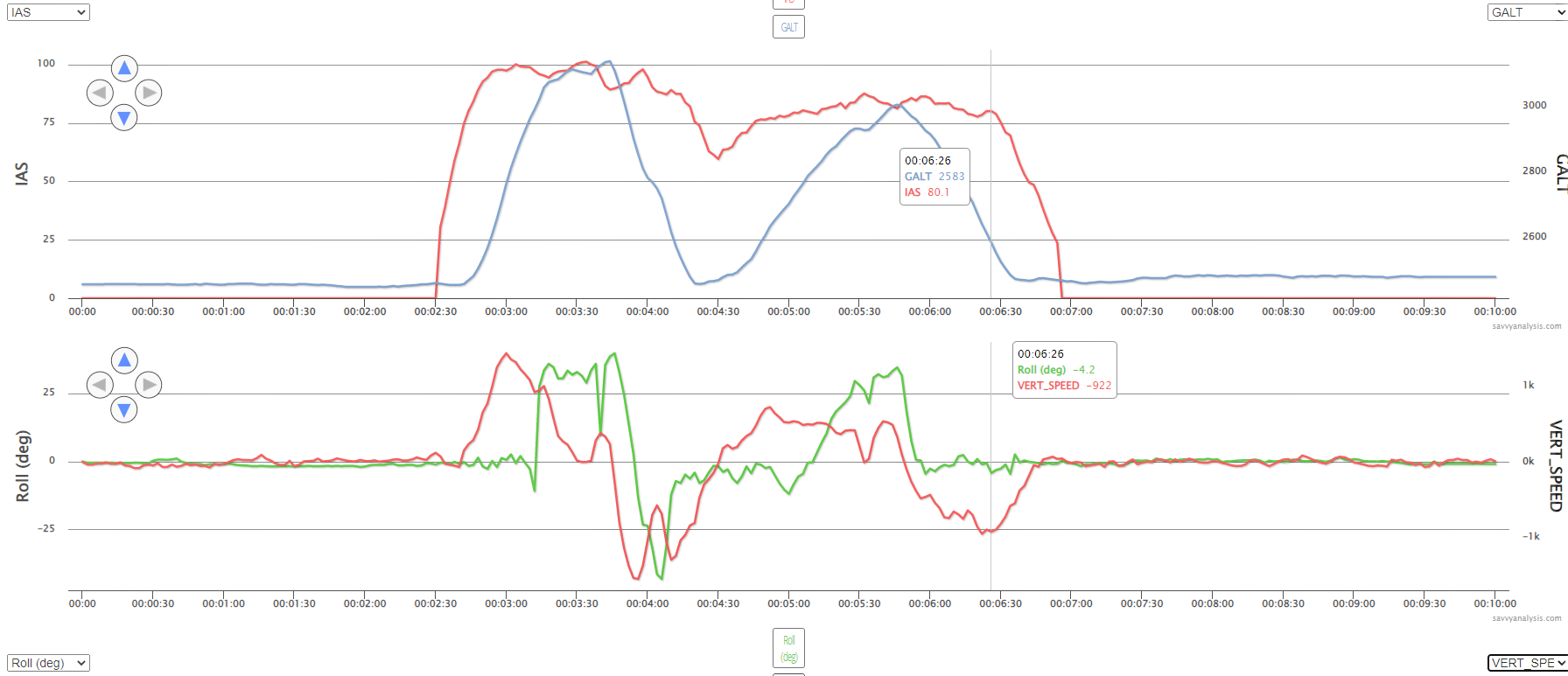

Here are the datas from the Skyview datalog:

The whole flight lasted four minutes. You can see this in the timelines from 02:30 to 06:30.

Note the RPM decrease at 06:30 when I pulled the mixture. The fuel flow went to zero while the RPM dropped from 1500 to 1100 RPM (windmilling).

Last Friday I was taking off from LOWZ airfield in Austria on Rwy 08 with my RV-7. When I reached a height of 500 ft the engine suddenly was shaking with a significant power loss. I immediately pushed the nose over and turned right knowing I hava to land ASAP. Two options came to mind - a short pattern or land on opposite rwy, chosed the second option as I was in a good position for it. I glanced at the instruments and saw cyl 2 is gone (not physically). Engine was still responsive but with reduced power and out of balance. I radioed I was having trouble and will come in on rwy 26. The approach was not pushed and good on speed and altitude being aware of about 2 kts tailwind on the 2500 ft rwy. I came in slightly high and the plane just didn´t wan´t to descent and become slower, somehow the engine was still producing power and I pulled hard on the throttle - no change.

Now I realized I will not make it and end up in the bushes at the end of the rwy. I made a bad decision but was lucky with it and did go around being aware I could crashland in the golf course ahead. I retracted the flaps to 10 and did a shallow climb with a slight left turn for a teardrop pattern. Then I came in high assuring to make the rwy. Again the airplane didn´t want to descent as usual, there is still the power just like on the first approach. I pulled the mixture and shut the engine down and she descendet normal towards the rwy for a reliefing landing. During rollout I pushed the mixture in again to keep the engine running for a taxi-out. I realized that the RPM was around 1200 while it should be around 650 - so it was really running with power and this explains the unsuccessful approach.

I can tell you that during these two seconds floating over the rwy realizing not to make it and having two bad options left is no fun at all. It is completely different analysing this later on the ground with all the information available.

A question for the engine gurus here:

What could have caused the power increase at idle setting?

My guess is that the sticking exhaust valve in open position acted like an"aggressive cam" with some significant valve overlap so the idle MAP was increased (less vacuum in the intake manifold).

Here are the datas from the Skyview datalog:

The whole flight lasted four minutes. You can see this in the timelines from 02:30 to 06:30.

Note the RPM decrease at 06:30 when I pulled the mixture. The fuel flow went to zero while the RPM dropped from 1500 to 1100 RPM (windmilling).

Last edited: