Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RV8 cooling ramp cracks

- Thread starter Pilot8

- Start date

jbDC9

Well Known Member

I don’t know the ramp skin gauge on my -8, it’s whatever was standard on a 2004 vintage QB kit... I had multiple ramp cracks within the first hundred hours running a 4 into 1 exhaust pipe with no downturned tip. I stop drilled the cracks, laid patches over the top, then installed a downturned exhaust tip. No more cracks at 1800 hours.

I don’t know the ramp skin gauge on my -8, it’s whatever was standard on a 2004 vintage QB kit... I had multiple ramp cracks within the first hundred hours running a 4 into 1 exhaust pipe with no downturned tip. I stop drilled the cracks, laid patches over the top, then installed a downturned exhaust tip. No more cracks at 1800 hours.

Ditto all that for me, except that I have the standard four-in-to-two cross-over exhaust. The stop-drilled cracks have been there now for fifteen years, and my thought is that the down-turned tips “fixed” the problem of beating up the skin.... yet I am but a single data point blowing in the exhaust stream.....

Carl Froehlich

Well Known Member

For those still building, consider replacing the provided aluminum cooling ramp with 0.015” SS. This also complements firewalls insulated with Fiberfrax and a thin SS clad.

Use the provided aluminum cooling ramp as a template to fabricate this SS replacement. It only takes a few minutes to get the curved front end just right.

Carl

Use the provided aluminum cooling ramp as a template to fabricate this SS replacement. It only takes a few minutes to get the curved front end just right.

Carl

Last edited:

scsmith

Well Known Member

For those still building, consider replacing the provided aluminum cooling ramp with 0.15” SS. This also complements firewalls insulated with Fiberfrax and a thin SS clad.

Use the provided aluminum cooling ramp as a template to fabricate this SS replacement. It only takes a few minutes to get the curved front end just right.

Carl

Plus one on making a stainless steel ramp. Carl meant 0.015”.

As a datapoint, I have a vetterman crossover exhaust with downturns.( or should I say turn-downs?

Last edited:

fl-mike

Well Known Member

For those still building, consider replacing the provided aluminum cooling ramp with 0.015” SS. This also complements firewalls insulated with Fiberfrax and a thin SS clad.

Use the provided aluminum cooling ramp as a template to fabricate this SS replacement. It only takes a few minutes to get the curved front end just right.

Carl

That's what I did. Flatten the provided ramp to make the template for a stainless version. I also put some Dynamat on the inside to dampen any drumming.

RV8 Tunnel Issues

Yes deal with this while you’re building if you can. I have an early 2000’s vintage QB and wasn’t aware it was an issue. I had strong drumming in the floor boards, (wife would worriedly ask “what’s that”), and a crack developed in the tunnel at 150 hours. Not sure if engine prop combination matters but it’s an XP360 with a 200RV prop. It has the standard Vetterman exhaust with 2” pipes which he was just coming out with as I recall.

I ordered the turn downs to stop the drumming. Might have helped a little. I saw someone had created an insert for their tunnel and I decided to do that. I believe I used .032, bent the flanges on each side and tapered them toward the rear to match. I installed it right over the existing tunnel, prosealed the front on the firewall and riveted it in place It greatly reduced the drumming and so far no cracks.

I really felt I needed to do something substantial to address the vibration thus my aggressive approach.

Brett N

Yes deal with this while you’re building if you can. I have an early 2000’s vintage QB and wasn’t aware it was an issue. I had strong drumming in the floor boards, (wife would worriedly ask “what’s that”), and a crack developed in the tunnel at 150 hours. Not sure if engine prop combination matters but it’s an XP360 with a 200RV prop. It has the standard Vetterman exhaust with 2” pipes which he was just coming out with as I recall.

I ordered the turn downs to stop the drumming. Might have helped a little. I saw someone had created an insert for their tunnel and I decided to do that. I believe I used .032, bent the flanges on each side and tapered them toward the rear to match. I installed it right over the existing tunnel, prosealed the front on the firewall and riveted it in place It greatly reduced the drumming and so far no cracks.

I really felt I needed to do something substantial to address the vibration thus my aggressive approach.

Brett N

La_Rooster

I'm New Here

I saw someone had created an insert for their tunnel and I decided to do that. I believe I used .032, bent the flanges on each side and tapered them toward the rear to match. I installed it right over the existing tunnel, prosealed the front on the firewall and riveted it in place. It greatly reduced the drumming and so far no cracks.

Brett, do you have any pictures of your tunnel insert or its final installation to the firewall? I was thinking of doing something similar with titanium sheet and sandwiching some Fiberfrax and a couple extra stiffeners in there. Just wasn't sure about the best way to terminate it at the front where the curved portion is.

I'm still at a point where I can replace the whole ramp with stainless, but like the idea of having the Fiberfrax in there and don't want to bring that stuff on the cockpit side of the ramp.

chrispratt

Well Known Member

I discovered a crack within the first 50 hours (16 years ago). Stop-drilled it and has been fine ever since. Engine is an O-360-A1A, Hartzell constant speed prop, and Vetterman 4 into 2 exhaust. I finally added the exhaust turn downs five years after the first flight (about 380 hours). Immediately noticed a reduction in vibration and less fatiguing flight. Wish I had added these from the start. I can't say definitively that the turn downs would have eliminated the cracking issue but they certainly were a great addition just by reducing the vibration felt through my feet.

Chris

Chris

RV8JD

Well Known Member

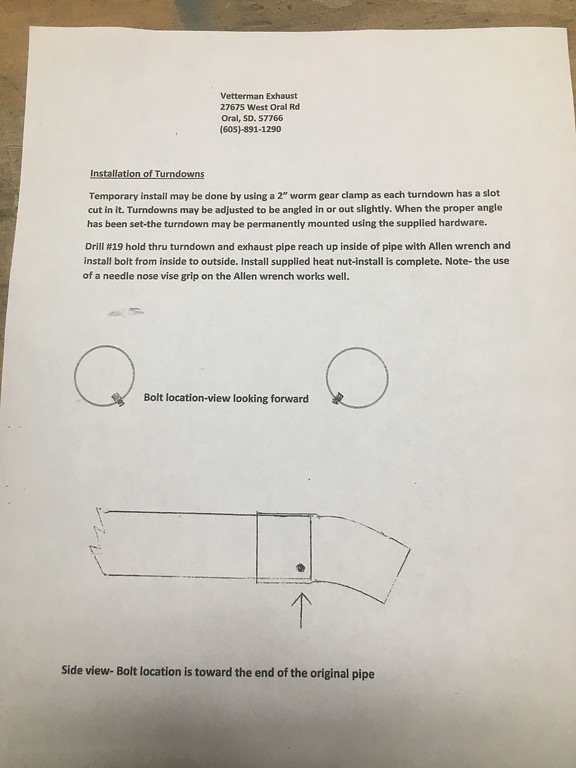

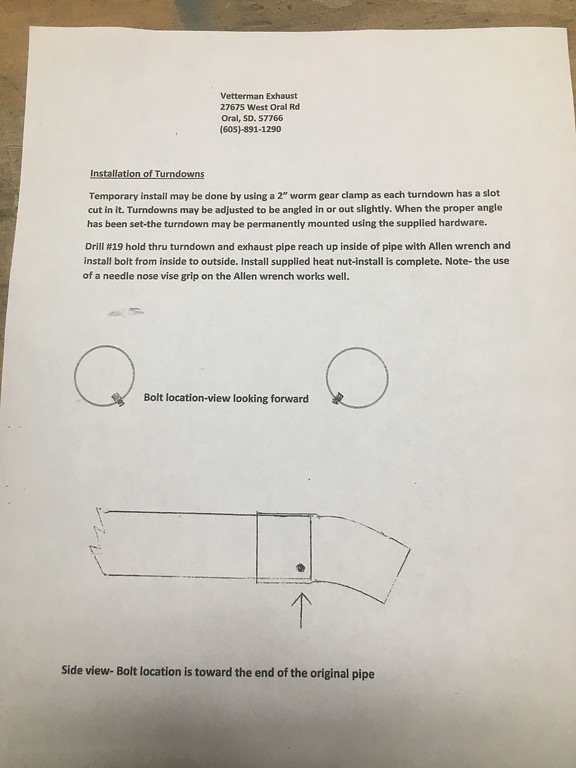

FWIW. I didn't have any belly skin cracks but wanted to reduce the floor vibration. Vetterman sells turndown extensions and straight extensions. I already had the turndown exhaust, but they were short. So Clint at Vetterman's sent me two short, straight extensions. They are each attached by one bolt. Hint: Put the bolt in per the instructions so the bolt is pointed toward the center of the airplane and not visible to a bystander standing next to the airplane (not like I did).

And the instructions:

And the instructions: