BuckWynd

Well Known Member

Time for a bit of a rant. Over the past two weeks, I have experienced TWO separate failures of what I consider to be inappropriate electrical connectors. One of them resulted in a loss of power to the affected unit. One was caught before it could cause any issues. On top of this, I have received several reports from acquaintances over the past few years of similar issues.

All of them are related to what I call "non aerospace-grade" wire connectors in a couple of common, apparently-accepted formats, and they are in many of our electronic units. (And yes, all of these installations were installed in accordance with the manufacturer's instructions and good building practices.)

For several reasons, I will not discuss any aviation manufacturer names on this thread, and I think we should leave that out of the discussion. I just want to point out what I think are connectors that should NOT be in electronics that are subject to vibration levels like that of a light airplane.

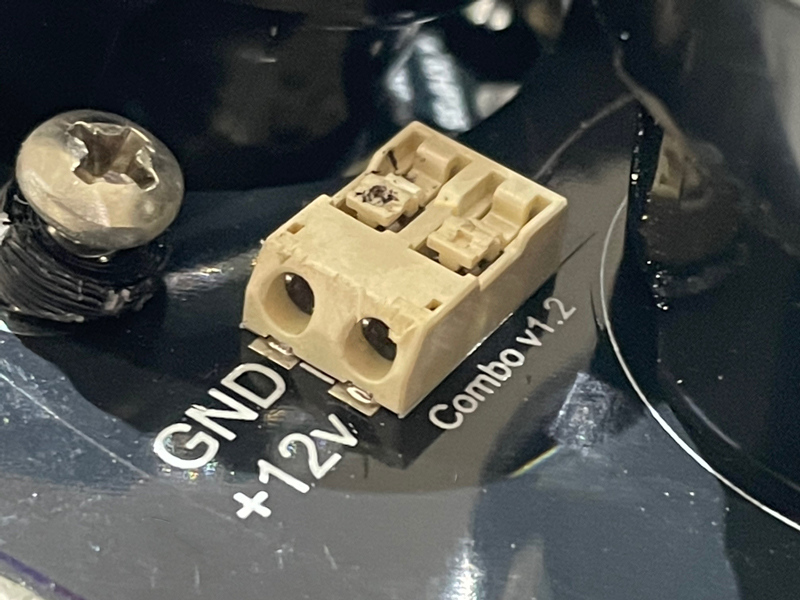

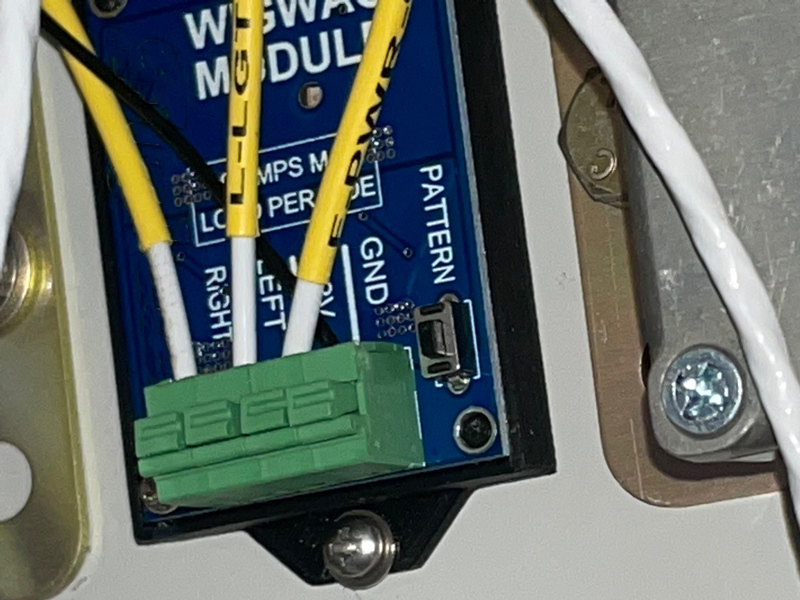

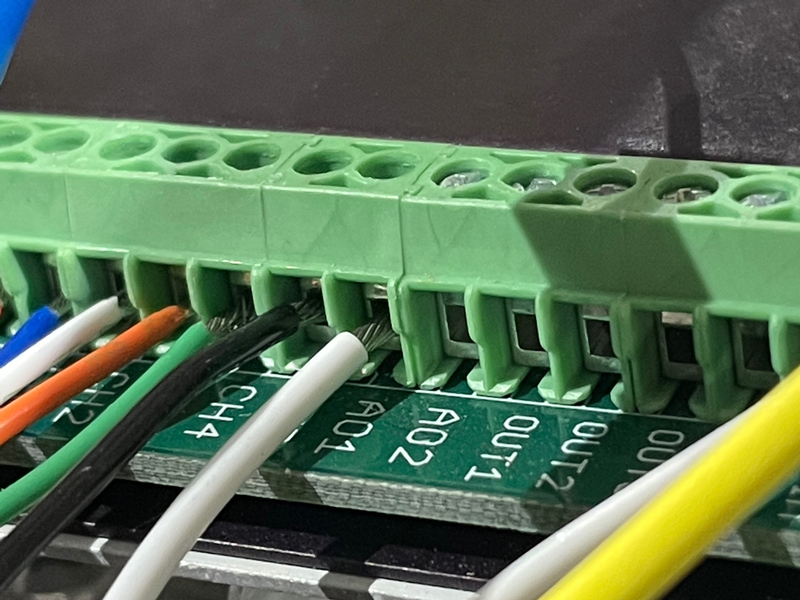

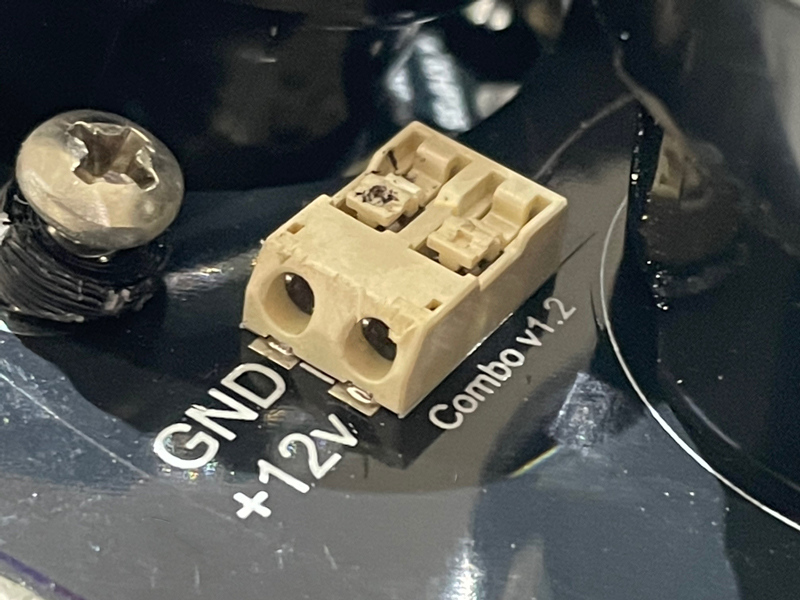

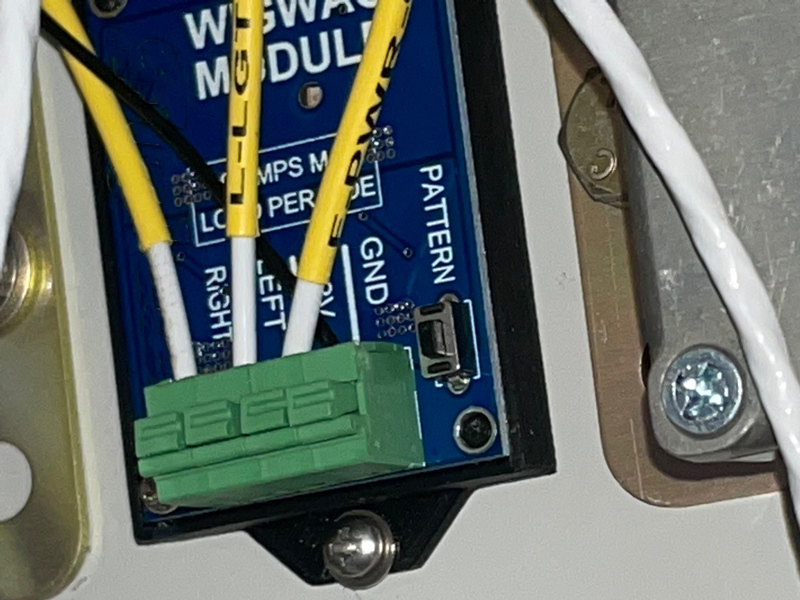

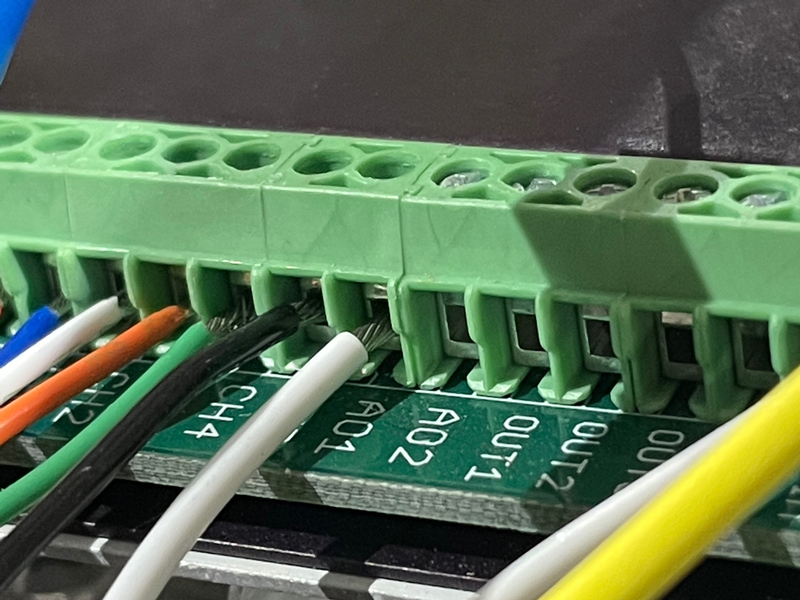

The photos below show the types of connectors I'm referring to. (These are not mine.) Both types require you to merely strip the wire and insert it into a recess. After that, the method of securing it is either 1). push the wire until it "locks" in place, or b). tighten a set-screw or plate onto the bare wire, flattening it down. The white one is called a "press-fit connector" or a "press connector," and the green one is called either a "pluggable terminal block," Euroblock, or Phoenix connector.

In my opinion, these are wonderful methods to secure your stereo speaker wires or your electronic hobby power supply cables, but they are alarmingly unsecure, subject to failure, and totally unsuitable for use in any aerospace vehicle except maybe a hobby drone.

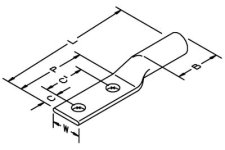

Bare wires tightened under a screw? Or worse, pushing a bare wire into a hole and hoping it stays there? Why, oh why, are we so accepting of this kind of nonsense in our airplanes? I spent over $700 on some really nice wire crimping tools of various kinds for my airplane project. I don't want some kind of half-baked hobby connectors on my critical flight gear. Give me a ring terminal ANY day. I am now to the point where I will never buy an aviation product, no matter how awesome it is, if it requires me to use a Euro connector.

I've never had a Molex, CPC, D-sub, PIDG Ring/Spade, Deutsch, Seal-All, or other normal connector simply disconnect or fall apart under normal conditions. So manufacturers, please stop using unsuitable, cheesy connectors in your aviation products!

And don't get me started on those tiny 26 AWG wires coming out of that certain brand of trim servo!

Is it just me? Sigh...

All of them are related to what I call "non aerospace-grade" wire connectors in a couple of common, apparently-accepted formats, and they are in many of our electronic units. (And yes, all of these installations were installed in accordance with the manufacturer's instructions and good building practices.)

For several reasons, I will not discuss any aviation manufacturer names on this thread, and I think we should leave that out of the discussion. I just want to point out what I think are connectors that should NOT be in electronics that are subject to vibration levels like that of a light airplane.

The photos below show the types of connectors I'm referring to. (These are not mine.) Both types require you to merely strip the wire and insert it into a recess. After that, the method of securing it is either 1). push the wire until it "locks" in place, or b). tighten a set-screw or plate onto the bare wire, flattening it down. The white one is called a "press-fit connector" or a "press connector," and the green one is called either a "pluggable terminal block," Euroblock, or Phoenix connector.

In my opinion, these are wonderful methods to secure your stereo speaker wires or your electronic hobby power supply cables, but they are alarmingly unsecure, subject to failure, and totally unsuitable for use in any aerospace vehicle except maybe a hobby drone.

Bare wires tightened under a screw? Or worse, pushing a bare wire into a hole and hoping it stays there? Why, oh why, are we so accepting of this kind of nonsense in our airplanes? I spent over $700 on some really nice wire crimping tools of various kinds for my airplane project. I don't want some kind of half-baked hobby connectors on my critical flight gear. Give me a ring terminal ANY day. I am now to the point where I will never buy an aviation product, no matter how awesome it is, if it requires me to use a Euro connector.

I've never had a Molex, CPC, D-sub, PIDG Ring/Spade, Deutsch, Seal-All, or other normal connector simply disconnect or fall apart under normal conditions. So manufacturers, please stop using unsuitable, cheesy connectors in your aviation products!

And don't get me started on those tiny 26 AWG wires coming out of that certain brand of trim servo!

Is it just me? Sigh...

Last edited: