Golf Echo

Active Member

Help! I'm kinda freaking out here...

I have match-drilled the left and right side HS skins to their respective substructures. Next, the book has you deburr all the holes. In deburring the holes on the rear spar, I noticed something horrible: oblong holes.

I used a #30 fluted reamer when I match-drilled HS-609PP to HS-603PP. I also used my 6000rpm Sioux drill. In doing some searching and reading of past posts, it now sounds like this was a REALLY bad combination.

In any event, I can't talk to Van's until Monday (which I am certainly planning on doing for a definitive answer). In the mean time, I'm hoping to get some guidance from the wealth of experience and knowledge on VAF.

Am I going to have to scrap the HS-609PPs and HS-603PPs and go shopping at Van's house of replacement parts?

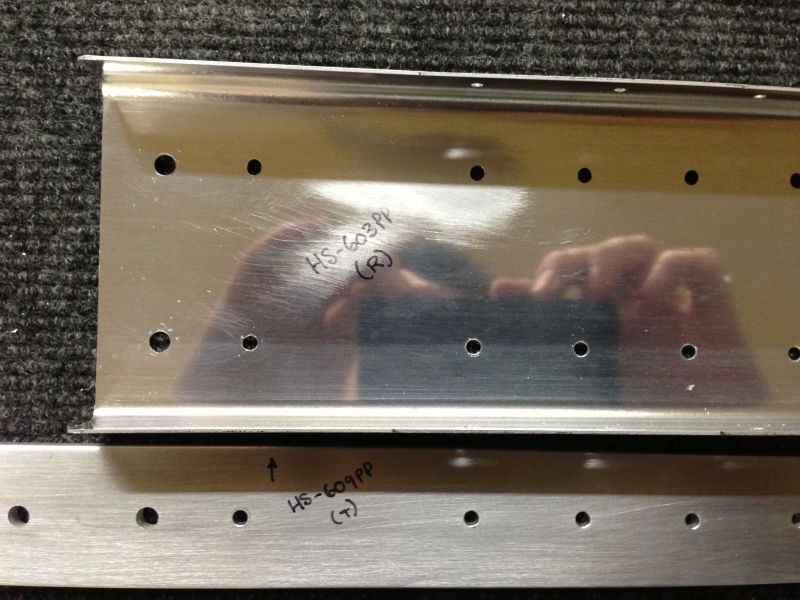

Here's the evidence:

This one looks REALLY bad. This is definitely the worst of it, and perhaps it looks worse in the photo than in person.

Thanks in advance

I have match-drilled the left and right side HS skins to their respective substructures. Next, the book has you deburr all the holes. In deburring the holes on the rear spar, I noticed something horrible: oblong holes.

I used a #30 fluted reamer when I match-drilled HS-609PP to HS-603PP. I also used my 6000rpm Sioux drill. In doing some searching and reading of past posts, it now sounds like this was a REALLY bad combination.

In any event, I can't talk to Van's until Monday (which I am certainly planning on doing for a definitive answer). In the mean time, I'm hoping to get some guidance from the wealth of experience and knowledge on VAF.

Am I going to have to scrap the HS-609PPs and HS-603PPs and go shopping at Van's house of replacement parts?

Here's the evidence:

This one looks REALLY bad. This is definitely the worst of it, and perhaps it looks worse in the photo than in person.

Thanks in advance