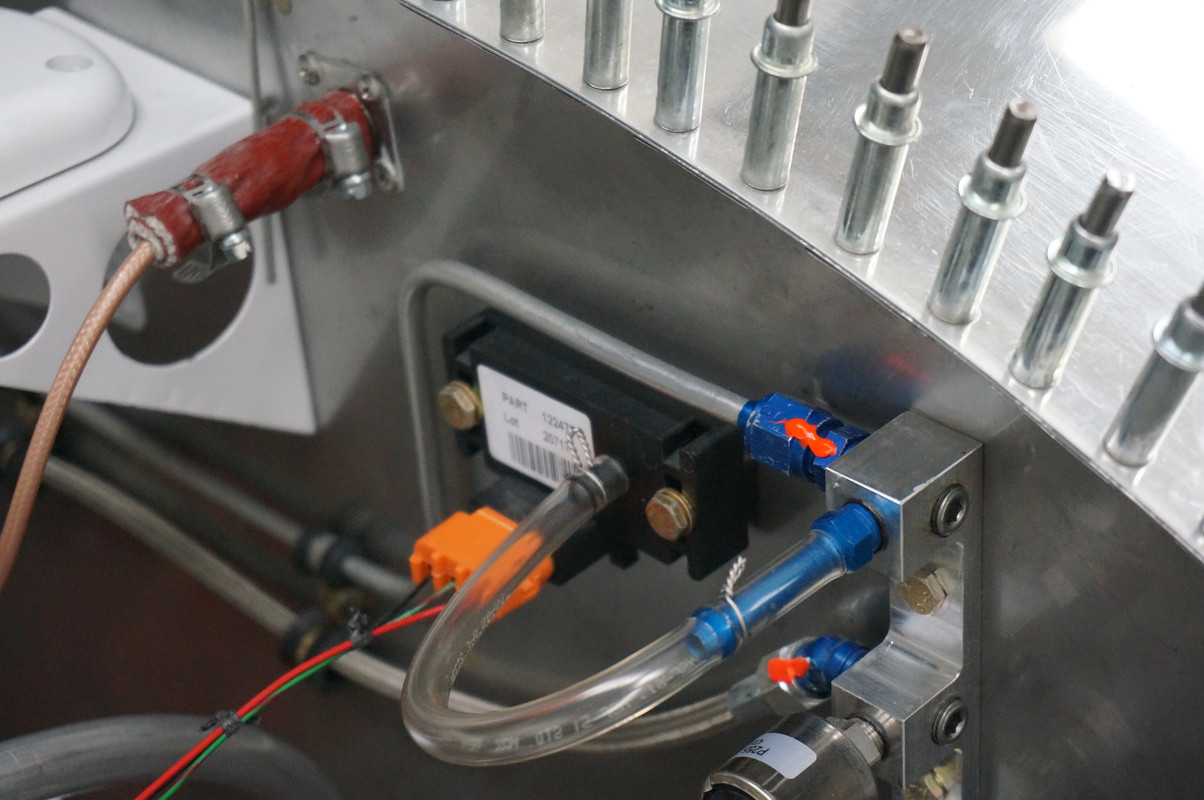

I need to install the MAP sensor and running a same air hose to the right PMAG on my engine. Unfortunately, I have the Dynon supplied MAP sensor, its inlet port is too large for the small Vans nylon hose in the kit. I also need to split the same MAP air line into the PMAG inlet. Both of the MAP sensor and PMAG have the same hose inlet size which is approximately 1/8".

What is the tubing material and hose connectors you guys use for the MAP sensor? The Vans MAP kit comes with a steel braided hose that connects from the #3 cylinder and has a restricted AN fitting at the other end. The plastic air line connects from this restricted AN fitting to the sensor.

Thanks in advance for any reply.

What is the tubing material and hose connectors you guys use for the MAP sensor? The Vans MAP kit comes with a steel braided hose that connects from the #3 cylinder and has a restricted AN fitting at the other end. The plastic air line connects from this restricted AN fitting to the sensor.

Thanks in advance for any reply.