walter

Well Known Member

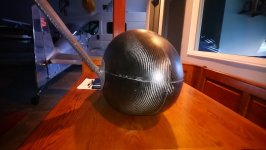

Was browsing the net and found a photo of the WAT (Whelen Aerospace Technologies) wheel pants for the Cirrus SR series aircraft. The wheel pant intersection fairing looks interesting. I wonder if it's more aerodynamic than our standard wheel pant fairings. Thoughts from the aerodynamically minded?

Wheel pant/Fairing:

Website Link: https://flywat.com/products/main-pants-cirrus-iceskates

Wheel pant/Fairing:

Website Link: https://flywat.com/products/main-pants-cirrus-iceskates