Entrepreneurship / Marketing major chiming in…..be gentle.

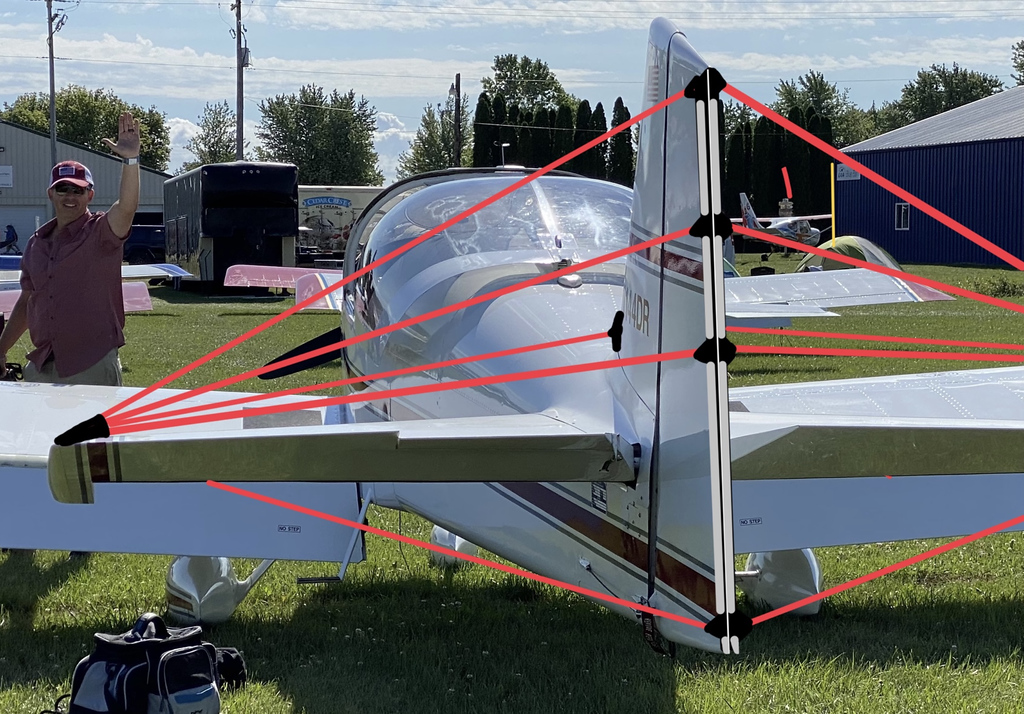

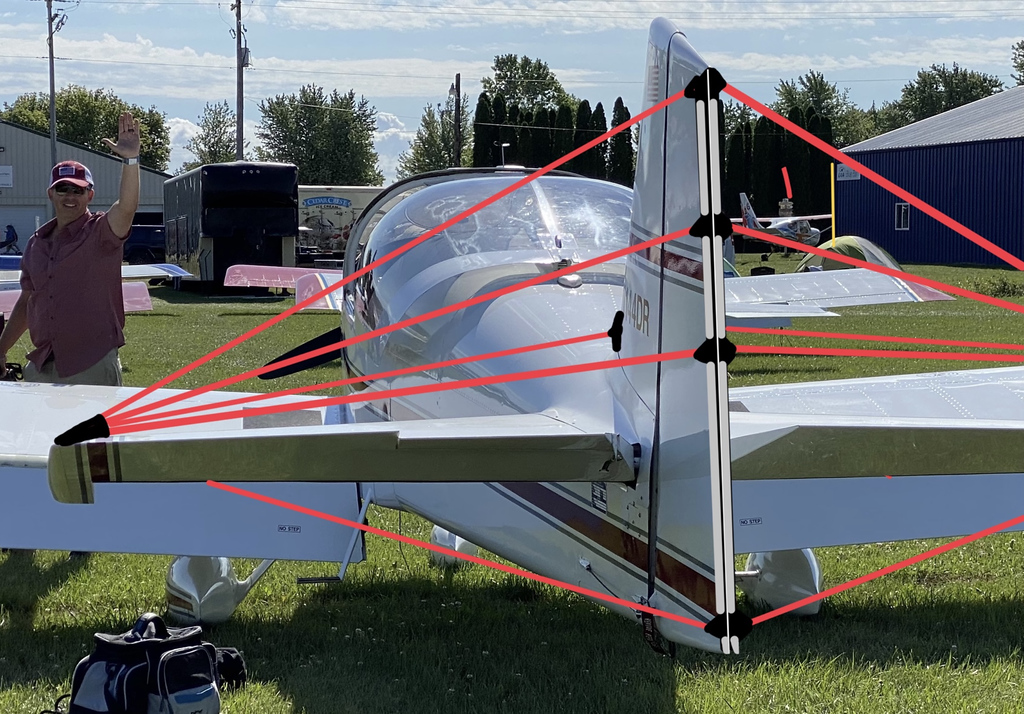

Please don’t call me an idiot too fast, but if you could connect two pieces of angled aluminum with a full length hinge, pad the inside surfaces, place that along the entire trailing edge length of the rudder, then hold that in place with bungee type cords running to the outboard ends of the HS.

Three or four small C-clamps gingerly holding the hinged contraption in place.

In a wind event, wouldn’t this apply the same tension along the entire length of the rudder?

Silly drawing below, note the bungee that runs in FRONT of the VS for stability.

A sort of ‘last resort’ OSH thing, not a use-all-the-time type thing.

Apologies in advance if this type thing has been discussed before ….. I haven’t seen anything that applies pressure along the entire trailing edge length of the rudder. That’s what I’m trying to address here

Shields up…crawling under the porch.

V/r,dr

Please don’t call me an idiot too fast, but if you could connect two pieces of angled aluminum with a full length hinge, pad the inside surfaces, place that along the entire trailing edge length of the rudder, then hold that in place with bungee type cords running to the outboard ends of the HS.

Three or four small C-clamps gingerly holding the hinged contraption in place.

In a wind event, wouldn’t this apply the same tension along the entire length of the rudder?

Silly drawing below, note the bungee that runs in FRONT of the VS for stability.

A sort of ‘last resort’ OSH thing, not a use-all-the-time type thing.

Apologies in advance if this type thing has been discussed before ….. I haven’t seen anything that applies pressure along the entire trailing edge length of the rudder. That’s what I’m trying to address here

Shields up…crawling under the porch.

V/r,dr

Last edited: