What is your typical Hobbs:Tach ratio? I just put my first 100 hours on and my ratio is 100:75. That indicates that I spend 1/4 of my time on the ground taxiing, warming up, or in the air practicing stalls. That doesn't seem right to me. Admittedly, my first 100 hours began in November and I probably saw more warm up time than I will in the next 6 months. But still...makes me wonder if clocks are working right.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hobbs vs Tach

- Thread starter wizard

- Start date

I'm not sure how your TACH time is set to record. On my Dynon FD180 EFIS/EMS here is an excerpt:

"The Tach Timer keeps track of engine time (normalized to the user-configured cruise RPM). The Hobbs Timer records the duration of time engine oil pressure is at 15 PSI or higher"

My Dynon originally defaulted with a higher number than I presently have set. I also had a large difference initially between the Hobbs and Tach times. My hobbs/tach are within about 5% after I adjusted the RPM setting for cruise (lowering the RPM). When the adjustment is made in the Dynon it actually changes the TACH time currently displayed using the RPM memory data residing in the EMS.

Check your configuration and you can probably narrow the ratio

"The Tach Timer keeps track of engine time (normalized to the user-configured cruise RPM). The Hobbs Timer records the duration of time engine oil pressure is at 15 PSI or higher"

My Dynon originally defaulted with a higher number than I presently have set. I also had a large difference initially between the Hobbs and Tach times. My hobbs/tach are within about 5% after I adjusted the RPM setting for cruise (lowering the RPM). When the adjustment is made in the Dynon it actually changes the TACH time currently displayed using the RPM memory data residing in the EMS.

Check your configuration and you can probably narrow the ratio

What is your typical cruise RPM vs. redline RPM? If you typically cruise at 2400 rpm using an everyday Lycoming, then your tach time during flight is less than 90% of your Hobbs. Now add in the time spent taxiing at 30%, and it is easy to see how you could end up with 75%.

Hobbs time is in many ways totally artificial - it gives no inkling as to how much work the engine has performed.

This (the Tach time being lower) is a GOOD thing, because your maintenance generally comes based on Tach time (or, how much work has the engine actually done).

Hobbs time is in many ways totally artificial - it gives no inkling as to how much work the engine has performed.

This (the Tach time being lower) is a GOOD thing, because your maintenance generally comes based on Tach time (or, how much work has the engine actually done).

John Myers

Member

Another data point for you, I am also using an AFS system and have about a 100:78 ratio (145h to 113t). That is pretty close to your ratio and may have more to do with the length of flight times than anything else. If the temp is colder than about 40 degrees F, I preheat and don't take off until oil temp comes up to about 115 degrees F. My ground run time is not normally very long that way and I live on a farm strip, so no long taxi times either. Hope that helps.

John Myers RV 8 N851JM

John Myers RV 8 N851JM

strahler13

Well Known Member

Vision?

Anybody know how the Vision hour meter would compare with a tach or Hobbs? Does it start "counting" at a certain RPM?

Thanks, Mark

Anybody know how the Vision hour meter would compare with a tach or Hobbs? Does it start "counting" at a certain RPM?

Thanks, Mark

Mark Albery

Well Known Member

Depending on the exact model of tacho, it will run true at a set RPM - typically 2400RPM. The Hobbs will record true time from master switch on to off unless it is fitted with an oil pressure or airspeed switch.

I usually cruise at 2200 RPM at low altitudes so my tacho is only recording 92% of true time in the cruise, less during descent and landing.

My Hobbs reads about 25% higher than the tacho.

Have a look at this to see how variable tach time can be.

Most renters charge Hobbs time because it gives the biggest number.

I usually cruise at 2200 RPM at low altitudes so my tacho is only recording 92% of true time in the cruise, less during descent and landing.

My Hobbs reads about 25% higher than the tacho.

Have a look at this to see how variable tach time can be.

Most renters charge Hobbs time because it gives the biggest number.

Greg Arehart

Well Known Member

I may be wrong, but my understanding was that Hobbs time is from engine on to engine off - basically any time there is oil pressure in the system. Tach time on the Dynon actually counts RPMs and then calculates time based on the user preset RPM. So if I set the "tach RPM" to 2700, I should get a much lower tach time than Hobbs time, since I rarely run at those RPMs! However, if I set the "tach RPM" to, say, 1800, then I might actually get a tach time that is LARGER than the Hobbs time, because I would be (normally) cruising at 22-2400 RPM which would compensate for the time I spend on the ground at 7-900 RPM.

I currently have my tach timer set for 2200 RPM, which is probably a bit lower than I normally cruise.

greg

I currently have my tach timer set for 2200 RPM, which is probably a bit lower than I normally cruise.

greg

80-20

My ratio has held very consistently at flight = 80% of hobbs. It been steady at that for about 8 years.

My ratio has held very consistently at flight = 80% of hobbs. It been steady at that for about 8 years.

What is your typical Hobbs:Tach ratio? I just put my first 100 hours on and my ratio is 100:75. That indicates that I spend 1/4 of my time on the ground taxiing, warming up, or in the air practicing stalls. That doesn't seem right to me. Admittedly, my first 100 hours began in November and I probably saw more warm up time than I will in the next 6 months. But still...makes me wonder if clocks are working right.

The EIS has a user settable RPM, above which time is counted. It doesn't average or normalize anything, it's either on or off based on an engine RPM "switch". I have mine set at 1400 RPM and it is amazingly close (within just a few minutes over almost 200 hours) in total time to my CNX-80, which is set to kick in at 40 knots ground speed. I consider my tach to be a pretty accurate representation of actual off-the-ground time.

To add a data point to the original poster, my tach time seems to run about 75% of the hobbs- same as yours.

To add a data point to the original poster, my tach time seems to run about 75% of the hobbs- same as yours.

Hobbs meter...

Hobbs meter is reading when the key is turned on until when it is turned off. this is not dependent on the engine running. That is why you want to be especially vigilant about turning off the master electrical switch when flying rental planes as they all use the Hobbs time for charging you for the rental. This is really easy to forget when the engine is turned off via fuel lever (which it should be). The Hobbs will keep running even tho the engine is not turning . Ask me how I know!

Hobbs meter is reading when the key is turned on until when it is turned off. this is not dependent on the engine running. That is why you want to be especially vigilant about turning off the master electrical switch when flying rental planes as they all use the Hobbs time for charging you for the rental. This is really easy to forget when the engine is turned off via fuel lever (which it should be). The Hobbs will keep running even tho the engine is not turning . Ask me how I know!

I may be wrong, but my understanding was that Hobbs time is from engine on to engine off - basically any time there is oil pressure in the system. Tach time on the Dynon actually counts RPMs and then calculates time based on the user preset RPM. So if I set the "tach RPM" to 2700, I should get a much lower tach time than Hobbs time, since I rarely run at those RPMs! However, if I set the "tach RPM" to, say, 1800, then I might actually get a tach time that is LARGER than the Hobbs time, because I would be (normally) cruising at 22-2400 RPM which would compensate for the time I spend on the ground at 7-900 RPM.

I currently have my tach timer set for 2200 RPM, which is probably a bit lower than I normally cruise.

greg

It as hinted at above, but just a note for those of you comparing tach times, the Dynon and AFS/GRT systems do it totally differently. The Dynon EMS systems actually normalize to an RPM, just like mechanical tach timers do. In a sense, they count actual revolutions of the engine, which is the whole reason that tach time is important. They read higher than 1 hour per hour if you are above your nominal RPM, and lower if you are lower. The system works at 600 RPM or 2700 RPM.

The AFS/GRT system is just a glorified hobbs timer. They just run 1 hour per hour when above a certain RPM. This is not tach time as defined by Lycoming or Continental.

If you cruise at 2300 RPM, but Lycoming says the nominal is 2400, then for every 24 hours you fly, you accumulate one more tach hour on a GRT or AFS than you do on a Dynon.

Of course, it's much harder to count actual revolutions on an engine than it is to just run a timer whenever RPM is greater than X, but we felt that if we were going to call it tach time, it should work like tach time.

Also, as a note, in many planes, hobbs is hooked to oil pressure, not the master. This is so you can't turn off the master and fly around while accumulating no hobbs time. In the Dynon EMS, hobbs runs whenever oil pressure is above 15 PSI. It does not accumulate just because the EMS is on.

The AFS/GRT system is just a glorified hobbs timer. They just run 1 hour per hour when above a certain RPM. This is not tach time as defined by Lycoming or Continental.

If you cruise at 2300 RPM, but Lycoming says the nominal is 2400, then for every 24 hours you fly, you accumulate one more tach hour on a GRT or AFS than you do on a Dynon.

Of course, it's much harder to count actual revolutions on an engine than it is to just run a timer whenever RPM is greater than X, but we felt that if we were going to call it tach time, it should work like tach time.

Also, as a note, in many planes, hobbs is hooked to oil pressure, not the master. This is so you can't turn off the master and fly around while accumulating no hobbs time. In the Dynon EMS, hobbs runs whenever oil pressure is above 15 PSI. It does not accumulate just because the EMS is on.

Garage Guy

Well Known Member

With E.I. instrumentation...

Another data point... We have Electronics International instruments for tach and Hobbs time in our RV-6. According to the manuals for these:

The E.I. R-1 tachometer "keeps a running total of time the engine is above 1300 RPM." Above that threshold it is evidently recording real clock time, not RPM-proportional time.

The E.I. SC-5 clock records the "total time the engine has been running." It decides the engine is running if the aircraft power bus is above 13 volts, which will normally be the case only if the alternator is spinning.

So, these are not doing exactly the same thing as a good old fashioned mechanical tach and oil-pressure Hobbs.

And we have 622.13 SC-5 time, 476.9 R-1 time. So tach is 77% of Hobbs, with this setup and our mix of flying.

--Paul

Another data point... We have Electronics International instruments for tach and Hobbs time in our RV-6. According to the manuals for these:

The E.I. R-1 tachometer "keeps a running total of time the engine is above 1300 RPM." Above that threshold it is evidently recording real clock time, not RPM-proportional time.

The E.I. SC-5 clock records the "total time the engine has been running." It decides the engine is running if the aircraft power bus is above 13 volts, which will normally be the case only if the alternator is spinning.

So, these are not doing exactly the same thing as a good old fashioned mechanical tach and oil-pressure Hobbs.

And we have 622.13 SC-5 time, 476.9 R-1 time. So tach is 77% of Hobbs, with this setup and our mix of flying.

--Paul

az_gila

Well Known Member

I'm not sure that is the standard.

The Hobbs meter is usually connected directly to the battery (bypassing the master switch) and is grounded (ie, switched on) by a pressure switch connected to the engine oil pressure.

This shows a certified 1977 era plane - the hour meter (aka Hobbs) is 2/3 down on the right side -

http://www.aucountry.com/ACA_Folder/Technical/Wire_Scan_76-77.jpg

The power to the Hobbs is a fuse under the cowl - not a breaker or fuse that is pilot accessible - so that a student can't reduce his/her bill by pulling a breaker...

I think the plane you are referring to might have been modified by an FBO/owner to get even more money...

Hobbs meter is reading when the key is turned on until when it is turned off. this is not dependent on the engine running. That is why you want to be especially vigilant about turning off the master electrical switch when flying rental planes as they all use the Hobbs time for charging you for the rental. This is really easy to forget when the engine is turned off via fuel lever (which it should be). The Hobbs will keep running even tho the engine is not turning . Ask me how I know!

The Hobbs meter is usually connected directly to the battery (bypassing the master switch) and is grounded (ie, switched on) by a pressure switch connected to the engine oil pressure.

This shows a certified 1977 era plane - the hour meter (aka Hobbs) is 2/3 down on the right side -

http://www.aucountry.com/ACA_Folder/Technical/Wire_Scan_76-77.jpg

The power to the Hobbs is a fuse under the cowl - not a breaker or fuse that is pilot accessible - so that a student can't reduce his/her bill by pulling a breaker...

I think the plane you are referring to might have been modified by an FBO/owner to get even more money...

Well, I guess I'll have to recheck that. the owner is a "good friend". I forgot the master switch and it ran for about 1 1/2 hours extra.Maybe he modified it?!

Or the pressure switch could be broken. However, in the distant past I have heard rumors of flight schools that have bypassed the oil pressure switch...

az_gila

Well Known Member

Probably not...

...since the "standard circuit" does not go through the master switch, it is driven directly off the battery. See schematic link above.

I'm not sure how standardized the circuit I mentioned is - does anyone have any different circuits from certified planes?

Or the pressure switch could be broken. However, in the distant past I have heard rumors of flight schools that have bypassed the oil pressure switch...

...since the "standard circuit" does not go through the master switch, it is driven directly off the battery. See schematic link above.

I'm not sure how standardized the circuit I mentioned is - does anyone have any different circuits from certified planes?

IowaRV9Dreamer

Well Known Member

I checked my 1980 Beech Skipper manual - the circuit is as shown above. There is a 5A cartridge fuse in the engine compartment (easily reachable through the oil door) that powers both the Hobbs and the clock.I'm not sure how standardized the circuit I mentioned is - does anyone have any different circuits from certified planes?

roadrunner20

Well Known Member

My hobbs is significantly larger than my tach time.

My TT is set for 1500rpm.

It is indicative of the way I fly. I fly alot of very short flights(10-15 mins) but my hobbs would record .4 to include the taxi.

(.2 TT : .4 hobbs)

Current numbers.

Hobbs: 332

TT: 228

My TT is set for 1500rpm.

It is indicative of the way I fly. I fly alot of very short flights(10-15 mins) but my hobbs would record .4 to include the taxi.

(.2 TT : .4 hobbs)

Current numbers.

Hobbs: 332

TT: 228

This all brings up an interesting question. A LONG time ago I was told that the Tach time was meant to register 1:1 at 100% rpm, not at "cruise rpm." This was because the actual wear on the engine is related to power setting, and that if you ran at lower power settings you could (intuitively) run the engine "longer" between scheduled maintenance times.

So, if you perform a "100 hour inspection" based on Tach time rather than Hobbs (which sounds like both a reasonable and desirable thing to do) but you have your tach time set to 1:1 at 2400 rpm, it seems like you are stabbing yourself in the foot (100 hours will come almost exactly at 100 Hobbs hours, rather than after the number of revolutions equal to 100 hours at 100% rpm).

Making matters even worse (from the perspective of your pocketbook), if you routinely fly at high altitudes even running 100% rpm may not be particularly harsh on your engine (65% power at 12,500').

So, for those of you with a better head for real-life and regulatory considerations, would you please enlighten us as to what we should actually be setting our Tach time RPM to and why?

So, if you perform a "100 hour inspection" based on Tach time rather than Hobbs (which sounds like both a reasonable and desirable thing to do) but you have your tach time set to 1:1 at 2400 rpm, it seems like you are stabbing yourself in the foot (100 hours will come almost exactly at 100 Hobbs hours, rather than after the number of revolutions equal to 100 hours at 100% rpm).

Making matters even worse (from the perspective of your pocketbook), if you routinely fly at high altitudes even running 100% rpm may not be particularly harsh on your engine (65% power at 12,500').

So, for those of you with a better head for real-life and regulatory considerations, would you please enlighten us as to what we should actually be setting our Tach time RPM to and why?

I'm not sure what's going on with mu system. My HOBBS and Tach time are pretty close, but the Hobbs time compared to actual time from Foreflight, Flight Aware are way off. Foreflight and Flight Aware are within a minute or two every time. But compared to Hobbs are way off, like Hobbs will be 1.5 when in reality the flight was 2 hours.

Mechanical Tachometers...radial vs lyco

I know a guy with a mech. tach. in his plane, builder says it came from a plane with a radial engine, so it doesn't read quite right for a lyco. Some (A&P) have said this was horse sheit, some have said it has merit. I really found nothing on the goog to support or deny. Assuming the rpm regime of the radial is different then this dynon normalization rpm would be different, and the builder would be right!

Anybody know?

I know a guy with a mech. tach. in his plane, builder says it came from a plane with a radial engine, so it doesn't read quite right for a lyco. Some (A&P) have said this was horse sheit, some have said it has merit. I really found nothing on the goog to support or deny. Assuming the rpm regime of the radial is different then this dynon normalization rpm would be different, and the builder would be right!

Anybody know?

Mechanical Tachometers...radial vs lyco

I know a guy with a mech. tach. in his plane, builder says it came from a plane with a radial engine, so it doesn't read quite right for a lyco. Some (A&P) have said this was horse sheit, some have said it has merit. I really found nothing on the goog to support or deny. Assuming the rpm regime of the radial is different then this dynon normalization rpm would be different, and the builder would be right!

Anybody know?

How would a tach know what kind of engine it's hooked up to? One rev is one rev, regardless of whether it's a radial, a flat, a V-12, your arm pulling the prop through...

How would a tach know what kind of engine it's hooked up to? One rev is one rev, regardless of whether it's a radial, a flat, a V-12, your arm pulling the prop through...

We are talking about the gauge's measure of Tach Hours, not its measure of RPM. Read back in the thread for that debate, mostly in reference to EFIS though. Still, Dynon chimed in that they do it like a mechanical tach.

We are talking about the gauge's measure of Tach Hours, not its measure of RPM. Read back in the thread for that debate, mostly in reference to EFIS though. Still, Dynon chimed in that they do it like a mechanical tach.

I understand that, and that a tach can be adjusted so that it is 1:1 at some set RPM. But how would that depend in any way on whether the engine was a Pratt & Whitney vs. a Lycoming?

builder says it came from a plane with a radial engine, so it doesn't read quite right for a lyco. Some (A&P) have said this was horse sheit, some have said it has merit.

I understand that, and that a tach can be adjusted so that it is 1:1 at some set RPM. But how would that depend in any way on whether the engine was a Pratt & Whitney vs. a Lycoming?

"Radial" is not a brand, you know this, but for those who may not. Now I assumed that anybody reading this would assume when I say Lyco(ming) I am referring to our typical flat 4 and 6 cylinder engines. So" radial vs lyco" means "Radial vs lycoming flat 4".

I suspect that many of the big radials, think Stearman or YAK 52, have a different "typical cruise RPM" than a Lyco, thus the tachometer would be set differently.

If all you're saying is that the tach had a calibrated 100% setting that was originally for some other engine (which happened to be a radial), yeah, okay. Nothing unusual there, that's what would almost *always* be the case.

There's no "Lycoming" set-point that's defined for a tach...it's up to the owner to define it wherever he or she wishes. 2300, 2400, 2500, 2700, whatever.

We had tachs set up for various RPMs on different airplanes in the flying club I was in, and occasionally we had them adjusted by the instrument shop to a different value.

I guess I was thrown off by the implication that the cause of the difference was the type of engine, which has nothing to do with it other than that drove the cruise RPM setting that some previous owner liked.

There's no "Lycoming" set-point that's defined for a tach...it's up to the owner to define it wherever he or she wishes. 2300, 2400, 2500, 2700, whatever.

We had tachs set up for various RPMs on different airplanes in the flying club I was in, and occasionally we had them adjusted by the instrument shop to a different value.

I guess I was thrown off by the implication that the cause of the difference was the type of engine, which has nothing to do with it other than that drove the cruise RPM setting that some previous owner liked.

So you agree with the builder in this case, just disagree with his stated reason. I'm cool with that. But yes this conversation supports the idea that the tach in question is not going to be accurate for it's current airplane. I assume the setting is way off, or rather it is completely unknown, why else mention it. The hobbs time is used to recorded everything in the logs. Before this conversation I didn't even know that changing settings in a mechanical tach was a thing people do. FWIW the tach reads 600 and the hobbs reads 660. Thanks RV7A Flyer.

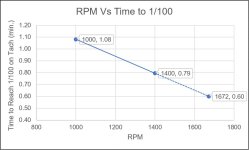

Did a little test yesterday. Ran the engine at 1000 RPM, recorded the actual time it took to register 1/100 hour on the tach. Repeated for 1400 rpm. Graphed it, extrapolated to 1/100 hour and got an RPM of 1672.

Now I don't know actually how it works in the tach but I would assume it is a linear trend. I only took 2 coarse data points, but I bet I am in the ballpark, for my Tach being set at 1672, plus or minus a couple hundred rpm.

Now I don't know actually how it works in the tach but I would assume it is a linear trend. I only took 2 coarse data points, but I bet I am in the ballpark, for my Tach being set at 1672, plus or minus a couple hundred rpm.