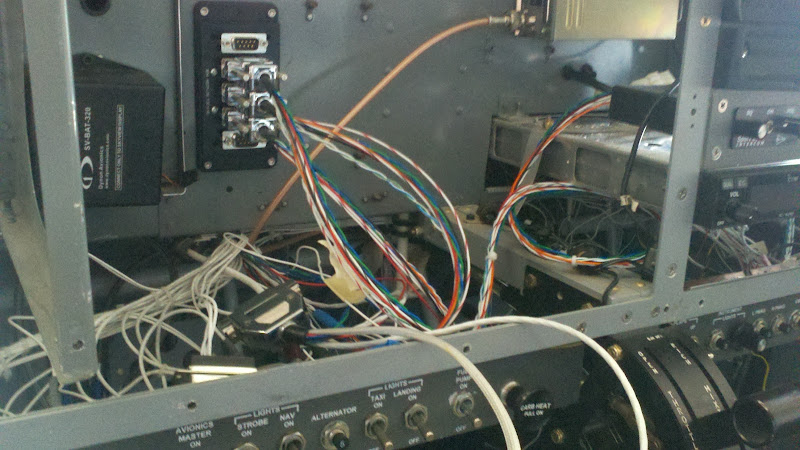

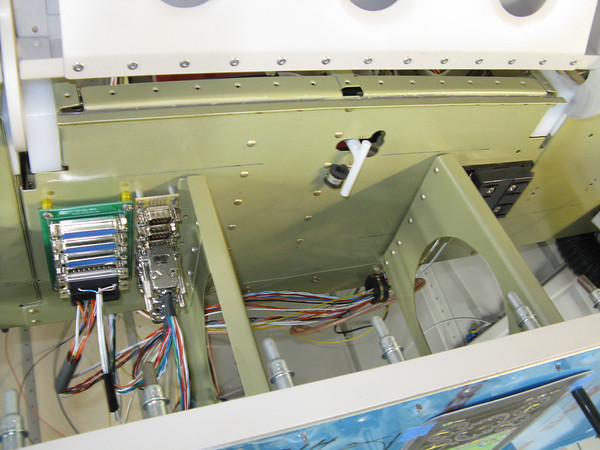

ron sterba

Well Known Member

RV9A. Starting my panel. I have a Dynon 10" with a ICOM 210 Comm. Did you use the standard panel from VANS or did you order the larger panel which extends down lower for switches ? Did anybody use a hinge to swing down their panel on pilots side with the Dynon 10" mounted. Where did you mount the transponder? Engine monitor module? Where did you place a pass-thru hole or holes, for engine probe wires? Power strip for 12V? Ground strip ?

I have entered into the DYNON ZONE, All welcome to give me a idea or a picture. Much appreciated!

Thanks Guys.

Ron in Oregon

I have entered into the DYNON ZONE, All welcome to give me a idea or a picture. Much appreciated!

Thanks Guys.

Ron in Oregon

Last edited: