bruceh

Well Known Member

Which is the better route for wires that are run across the top of the fuel and vent lines and then need to penetrate the spar carry through holes that are under the gear leg weldments?

Looks like the wires could go either forward or aft of the fuel & vent lines, then down to the hole.

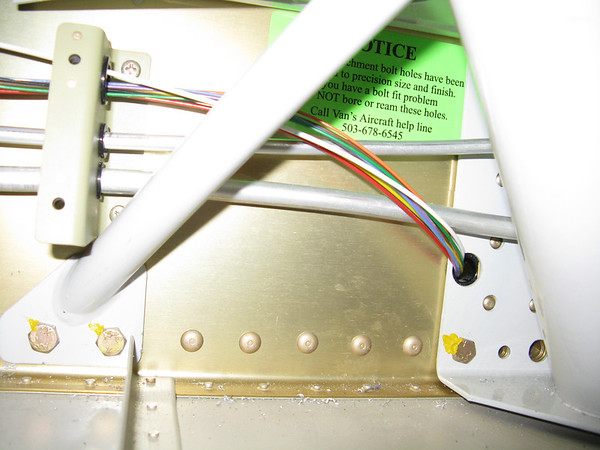

Here the wires are going forward of the fuel & vent lines.

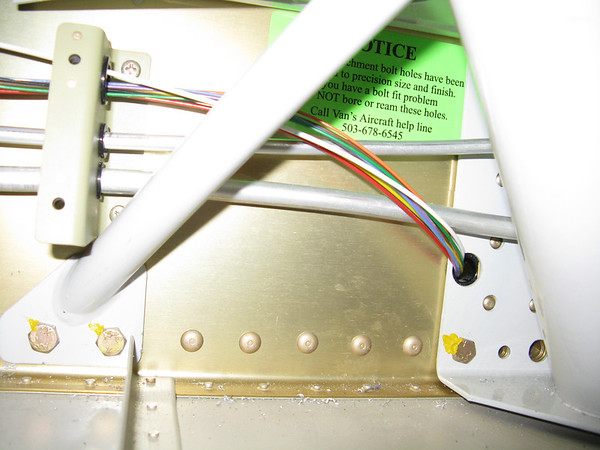

Here is the opposite side with the wires going behind the fuel & vent lines.

Before I start finishing up the wire runs, which way is preferred?

Looks like the wires could go either forward or aft of the fuel & vent lines, then down to the hole.

Here the wires are going forward of the fuel & vent lines.

Here is the opposite side with the wires going behind the fuel & vent lines.

Before I start finishing up the wire runs, which way is preferred?