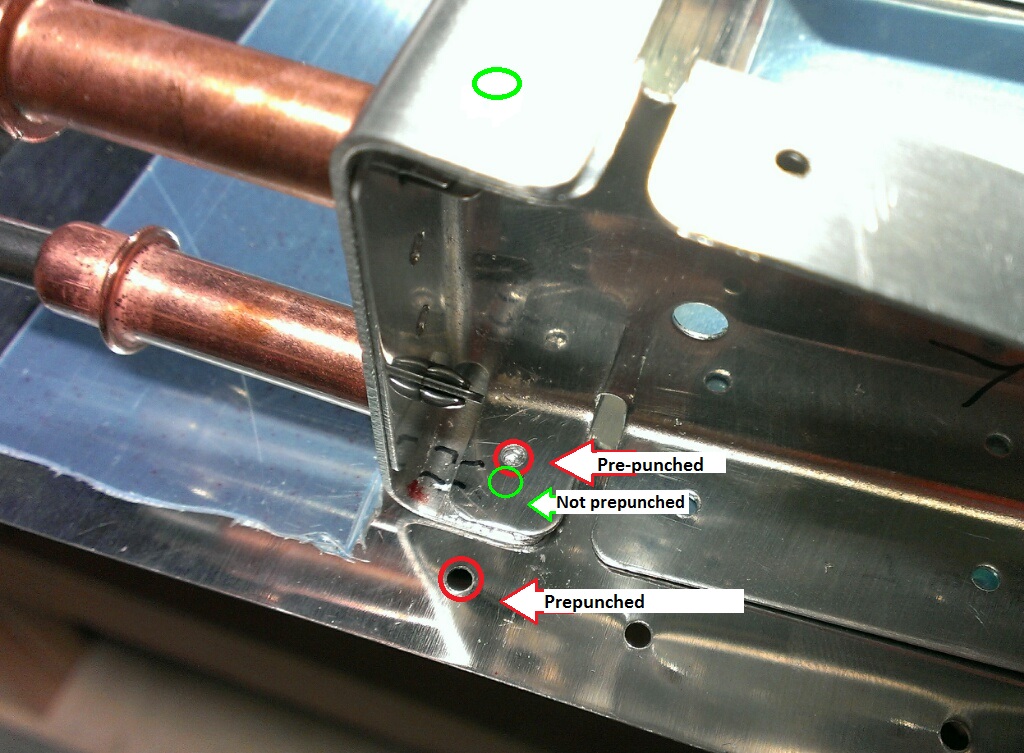

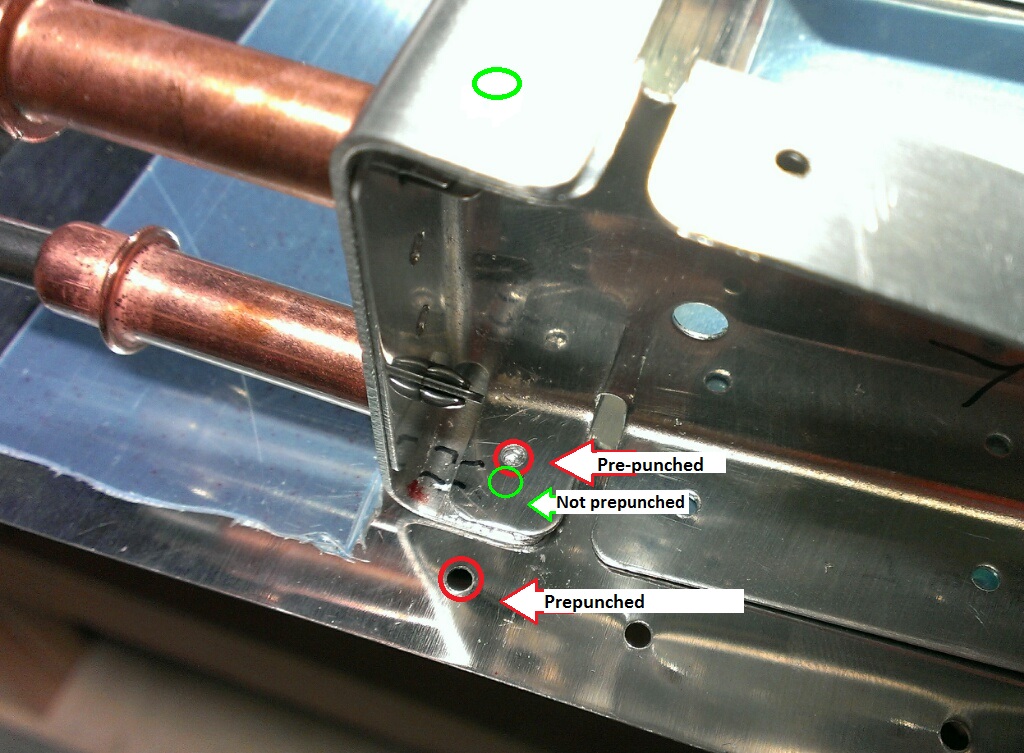

This is a good situation for practice. The challenge is that using a thin skin to keep your bit aligned is not a good situation. There is not enough area to keep the bit in place. This is a situation that will occur many times. You have several options.

Drill a proper hole in another piece of material about the thickness of the spar. Deburr, then as you have clamped and aligned all, and this is near the last hole, use this thicker piece as a drill guide to drill through the pieces.

Or - assemble, cleco, and get everything else aligned, then before you drill this missing hole, mark it with a sharpie through the skin on both sides, use a good set of magnifiers to center punch the hole position, (you may beed to dissemble to see it well) then drill it dissembled with 2 sizes smaller drill bit. Reassemble, use a punch to get best alignment, clamp with cleco or swivel foot vice grips (which ever you have and works best), and then match drill to final size.

I think the latter method would yield the best results.