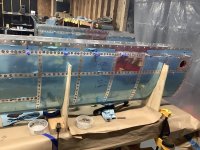

I finished closing up my tanks today, now waiting on Proseal to cure so I can leak check

A few questions.

1. Plans call for countersinking, then prosealing remaining rivet holes in rear baffle. This step is to be done after Proseal has cured..... how long should I wait? Clecos with blue tape.

2. Most folks say to wait a week or two to allow Proseal to cure before leak checking. Is there any guidance on how I can tell when the Proseal is fully cured? I planned on waiting at least a week.

3. Can I countersink, Proseal and rivet these 14 or so holes in the baffle when the Proseal has cured enough not to show a fingerprint

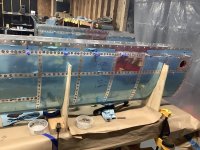

A few questions.

1. Plans call for countersinking, then prosealing remaining rivet holes in rear baffle. This step is to be done after Proseal has cured..... how long should I wait? Clecos with blue tape.

2. Most folks say to wait a week or two to allow Proseal to cure before leak checking. Is there any guidance on how I can tell when the Proseal is fully cured? I planned on waiting at least a week.

3. Can I countersink, Proseal and rivet these 14 or so holes in the baffle when the Proseal has cured enough not to show a fingerprint