swisseagle

Well Known Member

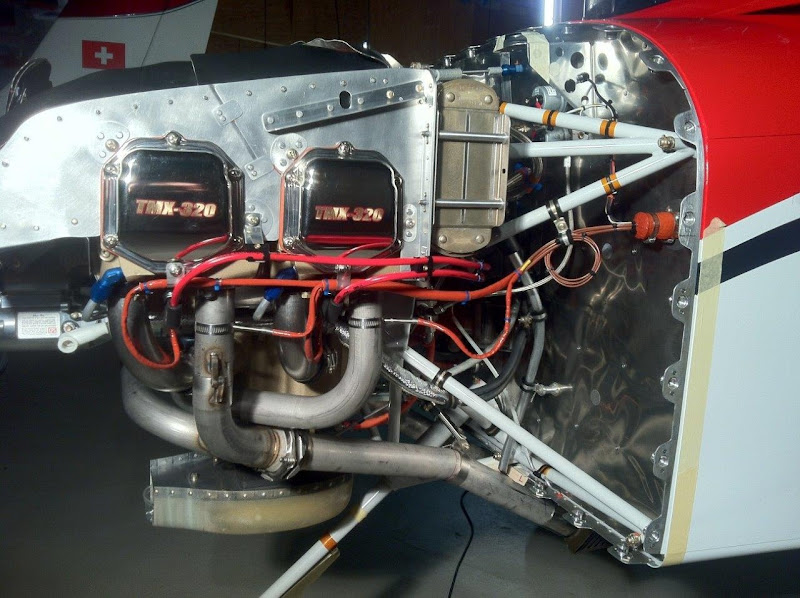

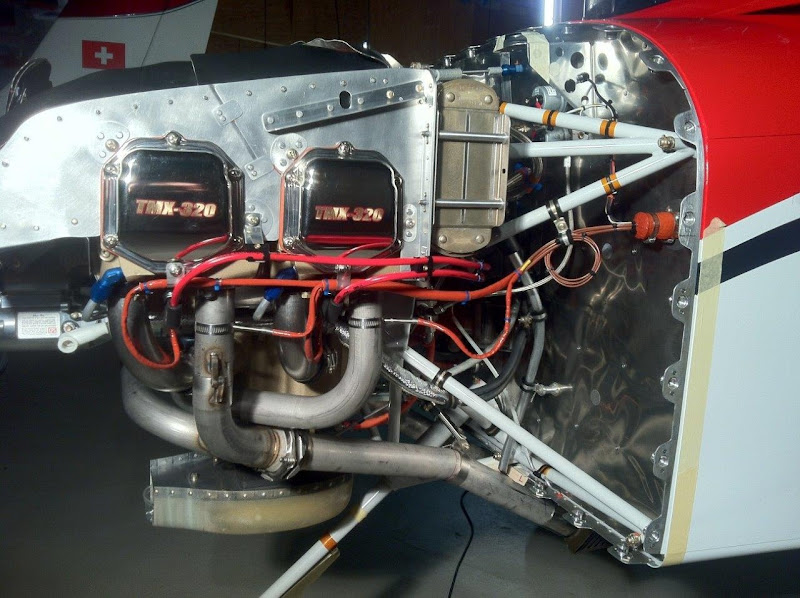

I’m short before the first engine run, what a task after 11 years of building!

Now the BIG question: What should be done to not harm the engine?

Mattituck TMX-IO-320, red gold

Roller tappet

AFS Fuel Injection

2x P-MAG

Sensenich metal FP

- Is there a Lycoming paper that describe this?

Otherwise I was thinking of this, but unsure:

- Drain anti rust oil, put a new oil filter on, refill with straight mineral oil (Phillips 20W50).

- Remove bottom spark plugs, drain any oil from the cylinder.

- Rotate propeller (x times?) to fill up the oil-system (filter, oil galley’s)?

- Check correct timing on the 2x P-MAG’s.

- Put in clean and proper gaped spark plugs.

- Purge the oil-pressure-line up to the pressure sensor?

- Purge the fuel pressure line up to the pressure sensor?

- Disconnect fuel line at the throttle body, flush fuel system with el. fuel pump, reconnect line.

- Fully charge the battery.

- As last step, connect the starter back again.

For sure also this:

- Put chocks under the wheel’s.

- Prepare fire extinguisher.

- Instruct ground crew.

- Mentally go thru engine start sequence.

- … wake up the engine and enjoy

Did I missed something?

The pictures are not brand new. In the mean time, the FWF section is finished, prop and spinner are on

Now the BIG question: What should be done to not harm the engine?

Mattituck TMX-IO-320, red gold

Roller tappet

AFS Fuel Injection

2x P-MAG

Sensenich metal FP

- Is there a Lycoming paper that describe this?

Otherwise I was thinking of this, but unsure:

- Drain anti rust oil, put a new oil filter on, refill with straight mineral oil (Phillips 20W50).

- Remove bottom spark plugs, drain any oil from the cylinder.

- Rotate propeller (x times?) to fill up the oil-system (filter, oil galley’s)?

- Check correct timing on the 2x P-MAG’s.

- Put in clean and proper gaped spark plugs.

- Purge the oil-pressure-line up to the pressure sensor?

- Purge the fuel pressure line up to the pressure sensor?

- Disconnect fuel line at the throttle body, flush fuel system with el. fuel pump, reconnect line.

- Fully charge the battery.

- As last step, connect the starter back again.

For sure also this:

- Put chocks under the wheel’s.

- Prepare fire extinguisher.

- Instruct ground crew.

- Mentally go thru engine start sequence.

- … wake up the engine and enjoy

Did I missed something?

The pictures are not brand new. In the mean time, the FWF section is finished, prop and spinner are on

Last edited: