Aero_Octaveus

Well Known Member

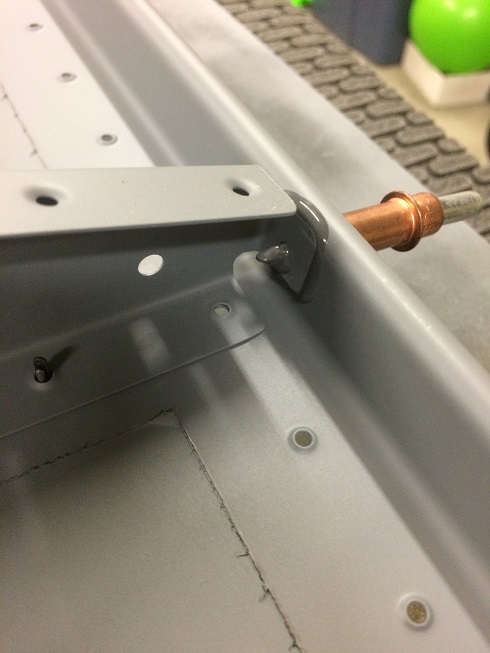

I have found a good way to destroy a cleco. Use 3m 2216 structural epoxy with a cleco.

The best part is that from the outside....it looks fine. But it's not inside!!!!

The best part is that from the outside....it looks fine. But it's not inside!!!!