Renaudvator

I'm New Here

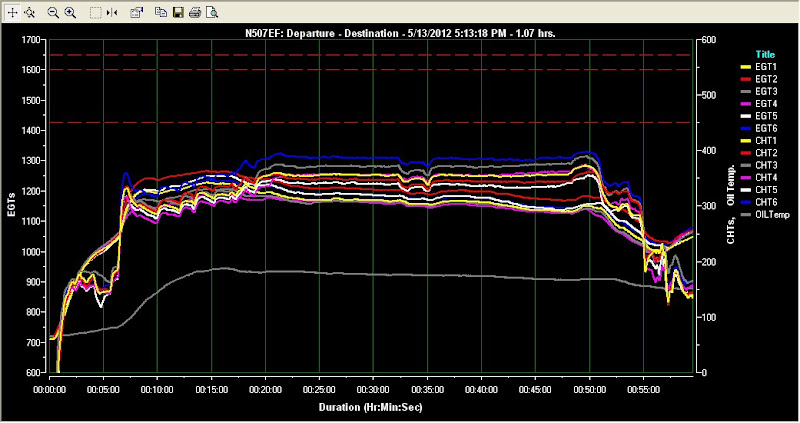

Would like to hear from southern RV10 builders about controlling oil temps and CHT's. I'm a short timer, 21hrs on Hobbs, and temps are running in the 430's.

Would like to hear from southern RV10 builders about controlling oil temps and CHT's. I'm a short timer, 21hrs on Hobbs, and temps are running in the 430's.

The stock engine in the stock -10 cowl installed in the stock way with good stock baffles should not be running that hot. I would first go through the other suggestions for mag timing, leaning and baffle sealing. Louvers definitely help, and I especially think one on the side by the oil cooler is a good idea, but you should be able to get acceptable temps without extra louvers. I would start with good baffles and the other things mentioned and then add louvers. Extra exit area means extra drag. Inefficient cooling because of baffle leaks is what you want to avoid. Efficient cooling with good tight baffles is one of the things that make these planes faster than the Cherokees and Cessnas out there with massive inlets and terrible baffles.