Flying again!

Well Known Member

I just did a condition inspection and found that the prop control cable on my -10 had melted the outside cover (it passes along the left side of the sump and up to the govenor at the front left of the O-540.

Troy Thompson who signed off on the inspection said he thought it was from heat soak. He said during a group X-country one of the RV-8s had the throttle freeze after a refueing stop. Apparently it got so hot that the inner liner melted and froze the cable.

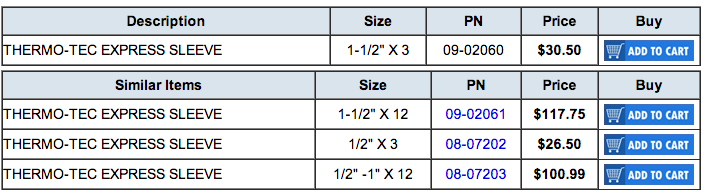

Mine was not that bad and it still functions normally. However, I bought HeatShield 270012 Thermaflect Sleeve 1/2" ID x 3' Heat Shield Sleeve for $16 from Amazon. It is rated for 1100 degrees F. I saw some evidence of the same with the throttle and mixture cables too.

The strange thing is that the -10 has over 360 hours and I have owned it for 18 months and over 150 hours. I check the engine very carefully at each oil change and did not see any damage at the end of October during the last oil change.

Here a a couple of pictures.

[/IMG]

[/IMG]

Troy Thompson who signed off on the inspection said he thought it was from heat soak. He said during a group X-country one of the RV-8s had the throttle freeze after a refueing stop. Apparently it got so hot that the inner liner melted and froze the cable.

Mine was not that bad and it still functions normally. However, I bought HeatShield 270012 Thermaflect Sleeve 1/2" ID x 3' Heat Shield Sleeve for $16 from Amazon. It is rated for 1100 degrees F. I saw some evidence of the same with the throttle and mixture cables too.

The strange thing is that the -10 has over 360 hours and I have owned it for 18 months and over 150 hours. I check the engine very carefully at each oil change and did not see any damage at the end of October during the last oil change.

Here a a couple of pictures.