FireMedic_2009

Well Known Member

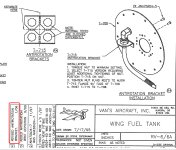

I'm nearing the end of the build for an inspection. I viewed all the SB's and the only one I'm lacking is the fuel pickup SB. I bore scoped the fuel pickup through the fuel sump and the safety wire wasn't done. The builder prosealed the side circular panel and the fuel gauge panel instead of using the cork gasket . I tried to use a metal putty knife to try to get behind the plate to separate it but was unable to even get the outer tip of the putty knife behind the plate.

The tanks are already installed and unlike the RV6 the tank is also secured to the wing spar with 18 bolts (6 rows of 3 bolts each). I'm trying not to remove the tank if possible.

Does anyone have any ideas? Worse case would be to remove the tank and if unable to remove the circular panel would be to cut a hole in the rear baffle and proseal behind the AN nut around the tube to keep the nut from loosening.

Thanks,

Daren

The tanks are already installed and unlike the RV6 the tank is also secured to the wing spar with 18 bolts (6 rows of 3 bolts each). I'm trying not to remove the tank if possible.

Does anyone have any ideas? Worse case would be to remove the tank and if unable to remove the circular panel would be to cut a hole in the rear baffle and proseal behind the AN nut around the tube to keep the nut from loosening.

Thanks,

Daren